Top Tips for Outdoor Displaying PCBs: What to Know

By:Admin

Outdoor displaying PCB (printed circuit board) has become an integral part of the signage and outdoor advertising industry. These PCBs are used to power and control various outdoor display systems such as electronic billboards, digital signage, and LED screens. With the rise of digital advertising, the demand for high-quality outdoor displaying PCBs has seen a significant increase in recent years. In response to this growing demand, companies like {} have been at the forefront of developing cutting-edge outdoor displaying PCB technologies.

{} is a leading manufacturer and supplier of outdoor displaying PCBs. With over 20 years of experience in the industry, the company has established itself as a trusted partner for businesses looking to enhance their outdoor advertising and signage solutions. {} offers a wide range of outdoor displaying PCB products, including single and double-sided PCBs, multi-layer PCBs, and flexible PCBs, to meet the diverse needs of their customers.

The outdoor displaying PCB industry has seen rapid technological advancements in recent years, driven by the increasing demand for energy-efficient and high-definition outdoor display systems. {} has been at the forefront of these developments, continuously innovating its product offerings to meet the evolving needs of the market. The company has invested heavily in research and development to create PCBs that are not only robust and reliable but also capable of delivering stunning visual performance in various outdoor environments.

One of the key challenges in the outdoor displaying PCB industry is ensuring the durability and reliability of the PCBs in harsh outdoor conditions. Extreme temperatures, exposure to moisture, and potential physical damage from environmental factors are among the challenges that outdoor displaying PCBs must withstand. {} has addressed these challenges by employing advanced manufacturing processes and using high-quality materials to ensure that their PCBs meet the highest industry standards for reliability and longevity.

In addition to the technical aspects, {} has also focused on providing excellent customer service and support. The company works closely with its customers to understand their specific requirements and to provide tailored solutions that meet their needs. With a commitment to quality and customer satisfaction, {} has built a strong reputation as a reliable partner for businesses seeking high-performance outdoor displaying PCBs.

The future of the outdoor displaying PCB industry looks promising, with continued advancements in technology and an increasing demand for innovative outdoor display solutions. {} is poised to play a significant role in shaping the future of this industry, with its dedication to quality, innovation, and customer-centric approach.

In conclusion, outdoor displaying PCBs have become an essential component of the outdoor advertising and signage industry, driving the demand for high-quality and reliable PCB solutions. {} has established itself as a leading provider of outdoor displaying PCBs, offering a wide range of products and excellent customer support. With its focus on innovation and quality, {} is well-positioned to meet the evolving needs of the market and contribute to the growth of the outdoor displaying PCB industry.

Company News & Blog

Innovative Multilayer Flexible PCB Technology Offers Enhanced Performance

Multilayer Flex PCB: The Future of Electronic InterconnectivityIn today's fast-paced and interconnected world, the demand for smaller, more flexible, and more efficient electronic devices is higher than ever. As technology advances, so does the need for innovative printed circuit board (PCB) solutions that can keep up with the changing landscape of consumer electronics. One company that is at the forefront of this innovation is {company name}, a leading manufacturer of advanced electronic interconnect solutions.{Company name} specializes in the production of multilayer flex PCBs, which are designed to provide unparalleled flexibility, reliability, and performance for a wide range of electronic applications. These advanced PCBs are constructed using multiple layers of flexible substrate materials, which are combined to form a highly adaptable and durable interconnect solution. The result is a PCB that can be bent, twisted, and shaped to fit into even the most tight and compact electronic devices, without sacrificing performance or reliability.With the increasing demand for smaller and more powerful electronic devices, the need for flexible and reliable interconnect solutions has never been greater. As a leading manufacturer of multilayer flex PCBs, {company name} is committed to providing its customers with the most advanced and innovative interconnect solutions on the market. By leveraging cutting-edge manufacturing techniques and materials, the company is able to produce PCBs that are not only highly flexible and durable but also provide exceptional electrical performance and signal integrity.One of the key advantages of {company name}'s multilayer flex PCBs is their ability to withstand extreme environmental conditions. Whether it is in a high-temperature industrial application or a harsh outdoor environment, these PCBs are designed to provide reliable and consistent performance, even in the most challenging conditions. This makes them an ideal choice for a wide range of applications, including aerospace, automotive, medical, and consumer electronics, where reliability and performance are critical.In addition to their flexibility and reliability, {company name}'s multilayer flex PCBs are also designed to provide exceptional electrical performance. By utilizing advanced materials and construction techniques, the company is able to produce PCBs that offer high-speed signal transmission, low electrical loss, and minimal electromagnetic interference. This makes them an ideal choice for applications that require high-frequency operation, such as wireless communications, data processing, and high-speed computing.{Company name} is also committed to sustainability and environmental responsibility in its manufacturing processes. The company takes a proactive approach to reducing its environmental impact by using environmentally friendly materials and production techniques, and by adhering to strict environmental regulations and standards. This ensures that customers can rely on {company name} not only for high-quality and high-performance products but also for solutions that are eco-friendly and sustainable.As the demand for smaller, more flexible, and more efficient electronic devices continues to grow, the need for advanced interconnect solutions such as multilayer flex PCBs will become increasingly important. {Company name}'s commitment to innovation, quality, and sustainability makes it an ideal partner for companies looking to stay ahead of the curve in the ever-evolving world of electronic interconnectivity. With its advanced manufacturing capabilities, cutting-edge materials, and unwavering commitment to customer satisfaction, {company name} is well-positioned to lead the way in the development of the next generation of electronic interconnect solutions.

How Printed Circuit Assemblies are Changing the Electronics Manufacturing Industry

Printed Circuit Assy, also known as PCB assembly, is a critical part of the electronics manufacturing process. It involves assembling various electronic components onto a printed circuit board to create a functional electronic device. From simple consumer electronics to complex industrial machinery, PCB assembly is an integral part of the production process.Founded in 1990, and with over three decades of experience, our company has been a leading provider of PCB assembly services for a wide range of industries. With state-of-the-art facilities and a team of skilled professionals, we are committed to delivering high-quality PCB assemblies that meet the specific requirements of our clients.Our company offers a comprehensive range of PCB assembly services, including surface-mount technology (SMT) assembly, through-hole assembly, and mixed-technology assembly. Our advanced manufacturing capabilities allow us to handle complex PCB designs and produce high-quality assemblies with tight tolerances.In addition to our assembly services, we also provide comprehensive testing and inspection services to ensure the quality and reliability of our PCB assemblies. With advanced testing equipment and strict quality control processes, we are able to detect and rectify any potential defects or issues before the final products are delivered to our clients.One of the key strengths of our company is our ability to provide customized PCB assembly solutions to meet the specific needs of our clients. We work closely with our customers to understand their requirements and provide tailored assembly solutions that align with their design specifications, budget, and timeline.Over the years, our company has built a strong reputation for delivering high-quality PCB assemblies with exceptional reliability and performance. We have successfully served clients in various industries, including telecommunications, automotive, aerospace, medical, and consumer electronics.As a customer-centric company, we are committed to providing excellent service and support to our clients throughout the entire PCB assembly process. From initial design and prototyping to mass production and after-sales support, we work closely with our clients to ensure a seamless and efficient experience.In line with the ever-evolving nature of the electronics industry, our company continuously invests in the latest technology and equipment to enhance our manufacturing capabilities. We stay abreast of the latest industry trends and standards to deliver cutting-edge PCB assembly solutions that meet the demands of modern electronics applications.In addition to our commitment to quality and innovation, our company places a strong emphasis on environmental sustainability and social responsibility. We adhere to strict environmental regulations and promote eco-friendly practices in our manufacturing processes. Furthermore, we prioritize the well-being and safety of our employees, providing a conducive and inclusive work environment.Looking ahead, our company remains focused on driving technological advancements and delivering superior PCB assembly solutions to our clients. With a dedication to excellence and a passion for innovation, we are well-positioned to meet the evolving needs of the electronics industry and continue to be a trusted partner for our clients.In conclusion, Printed Circuit Assembly is a critical component of the electronics manufacturing process, and our company has established itself as a leading provider of high-quality PCB assembly services. With a strong focus on quality, innovation, and customer satisfaction, we are committed to delivering customized assembly solutions that meet the specific requirements of our clients. As we continue to invest in technology and expand our capabilities, we are poised to remain at the forefront of the PCB assembly industry.

Top tips for low volume PCB fabrication

Low Volume PCB Fabrication Made Easy with [Company Name]In today's fast-paced and technology-driven world, printed circuit boards (PCBs) play a crucial role in the functioning of various electronic devices. Whether it's a small handheld gadget or a complex industrial machinery, PCBs are at the heart of these electronic devices. However, for companies looking to produce low volumes of PCBs, finding a reliable and cost-effective fabrication solution can be a daunting task. This is where [Company Name] comes in, offering a seamless and efficient solution for low volume PCB fabrication.[Company Name] is a leading provider of PCB fabrication services, specializing in catering to the needs of small and medium-sized businesses that require low volumes of PCBs. With years of experience and expertise in the field, [Company Name] has established itself as a trusted partner for businesses looking for high-quality PCB fabrication without the high volume requirements typically demanded by other manufacturers.One of the key advantages of working with [Company Name] is their ability to provide customized solutions for low volume PCB fabrication. While many manufacturers prioritize large-scale production runs, [Company Name] understands the unique requirements of small and medium-sized businesses. They are able to provide personalized attention to each project, ensuring that the specific needs of their clients are met with precision and accuracy.In addition to customization, [Company Name] also offers a quick turnaround time for low volume PCB fabrication. Their streamlined production process, combined with state-of-the-art technology and machinery, allows them to efficiently fulfill orders without compromising on quality. This is a significant advantage for businesses that require a fast and reliable solution for their PCB fabrication needs.Furthermore, [Company Name] is committed to maintaining the highest standards of quality in their fabrication processes. They adhere to strict quality control measures at every step of the production cycle, ensuring that each PCB meets the exact specifications and performance standards required by their clients. This dedication to quality has earned [Company Name] a reputation for excellence in the industry, making them a preferred choice for businesses seeking reliable low volume PCB fabrication services.Another standout feature of [Company Name]'s services is their cost-effective pricing structure for low volume PCB fabrication. As a business-focused service provider, [Company Name] understands the importance of balancing quality and affordability. They have developed a pricing model that allows small and medium-sized businesses to access high-quality PCB fabrication services without breaking the bank. This makes [Company Name] an ideal partner for businesses looking to optimize their production costs while maintaining top-notch quality.Moreover, [Company Name] offers comprehensive support and guidance throughout the entire fabrication process. Their team of experienced professionals works closely with clients to understand their specific requirements and provide expert advice and recommendations. From initial design consultations to final product delivery, [Company Name] ensures that their clients are supported at every step, minimizing the complexities often associated with PCB fabrication.With [Company Name]'s low volume PCB fabrication services, businesses can enjoy a hassle-free and efficient solution for their PCB production needs. Whether it's a prototype for a new product or a small-scale production run, [Company Name] is dedicated to delivering the highest quality PCBs to meet the unique requirements of their clients.In conclusion, [Company Name] is revolutionizing the landscape of low volume PCB fabrication with their commitment to quality, affordability, and personalized service. Businesses looking for a reliable and efficient solution for their PCB fabrication needs can confidently turn to [Company Name] for a seamless and hassle-free experience. With their expertise and dedication to excellence, [Company Name] is poised to continue leading the way in low volume PCB fabrication, empowering businesses to bring their electronic innovations to life.

Get the Latest News on Filled Vias PCB Technology

A cutting-edge PCB technology has been developed by a renowned company, leading the way in innovative electronics manufacturing. Their new vias PCB technology is set to revolutionize the industry, offering faster and more efficient ways to create high-performance printed circuit boards.The vias PCB technology involves filling vias, which are small holes drilled into the PCB, with a conductive material. This allows for efficient conductivity between different layers of the PCB, improving the overall performance and reliability of the circuit board. The technology also allows for more compact and dense circuit designs, as the filled vias take up less space compared to traditional unfilled vias.With the introduction of this new technology, the company is positioning itself as a leader in the PCB manufacturing industry. Their commitment to innovation and their investment in research and development have allowed them to develop this cutting-edge technology, giving them a competitive edge in the market.The filled vias PCB technology offers a wide range of benefits for electronics manufacturers. The improved conductivity and reliability of the circuit boards mean that products can perform better and last longer. The compact nature of the filled vias also allows for smaller and more efficient designs, which is crucial in industries where space is at a premium, such as the automotive and aerospace sectors.In addition to the performance benefits, the new technology also offers cost savings for manufacturers. The more efficient use of space on the PCB means that less material is required, resulting in cost savings on production. The improved reliability of the circuit boards also means that there is less risk of defects or failures, reducing the need for costly repairs or replacements.The company's commitment to quality and innovation is evident in the development of the filled vias PCB technology. They have invested heavily in state-of-the-art manufacturing and testing equipment to ensure that their products meet the highest standards of performance and reliability. Their team of skilled engineers and technicians are dedicated to pushing the boundaries of PCB technology, and the introduction of the filled vias technology is a testament to their ongoing efforts.With this new technology, the company is set to make a significant impact in the electronics manufacturing industry. Their filled vias PCBs offer a new standard of performance and reliability, setting them apart from their competitors. As electronics continue to become smaller and more complex, the demand for high-performance PCBs will only continue to grow, and the company is well-positioned to meet this demand with their cutting-edge technology.Overall, the introduction of the vias PCB technology by the company {} represents a significant milestone in the electronics manufacturing industry. Their commitment to innovation and quality has resulted in a technology that offers improved performance, reliability, and cost savings for electronics manufacturers. As they continue to push the boundaries of PCB technology, the company is sure to remain at the forefront of the industry for years to come.

What is the Importance of Breakdown Voltage Testing?

Breakdown Voltage Test is a crucial procedure in the testing and quality control of electrical equipment. It refers to the maximum voltage that can be applied to a material without causing it to break down or become electrically conductive. This test is particularly important in the manufacturing of high voltage equipment to ensure the safety and reliability of electrical systems.At the forefront of developing advanced testing equipment for Breakdown Voltage Test is a leading company in the field of electrical testing and measurement technology. With a strong focus on innovation and quality, the company has been a trusted partner for industries worldwide.The Breakdown Voltage Test equipment developed by the company is designed to meet the highest standards of accuracy and reliability. It is capable of performing tests on a wide range of materials and electrical components, providing valuable data for the assessment of their insulation properties.In addition to standard Breakdown Voltage Tests, the company's equipment also offers advanced features such as automatic test sequences, data logging, and remote monitoring. This allows for efficient testing processes and detailed analysis of test results, ensuring that the highest level of precision is achieved.The company's expertise in Breakdown Voltage Test equipment extends to various industries including power generation, electrical utilities, manufacturing, and research laboratories. Their testing solutions have been instrumental in ensuring the safety and performance of critical electrical infrastructure and components.One of the key advantages of the company's Breakdown Voltage Test equipment is its versatility and ease of use. With intuitive interfaces and advanced software integration, the testing process can be streamlined for maximum efficiency. This not only saves time and resources but also allows for comprehensive testing of a wide range of electrical equipment.Furthermore, the company is committed to providing excellent customer support and technical assistance for their Breakdown Voltage Test equipment. Their team of experts offers training, maintenance services, and application support to ensure that their clients can fully utilize the capabilities of the testing equipment.In line with the company's dedication to innovation, they continue to invest in research and development to further enhance their Breakdown Voltage Test solutions. Their ongoing efforts in improving testing accuracy, automation, and data management demonstrate their commitment to staying at the forefront of the industry.As the demand for high-quality Breakdown Voltage Test equipment continues to grow, the company remains focused on meeting the evolving needs of the market. Their ability to adapt to changing industry requirements and deliver cutting-edge testing solutions has established them as a leader in the field of electrical testing and measurement technology.In conclusion, Breakdown Voltage Test is a critical aspect of ensuring the safety and reliability of electrical equipment, and the company's advanced testing solutions are playing an essential role in meeting this need. With a strong emphasis on innovation, quality, and customer satisfaction, the company is well-positioned to continue driving advancements in Breakdown Voltage Test technology and contribute to the success of industries worldwide.

Top Ways LED PCB Boards are Revolutionizing the Technology Industry

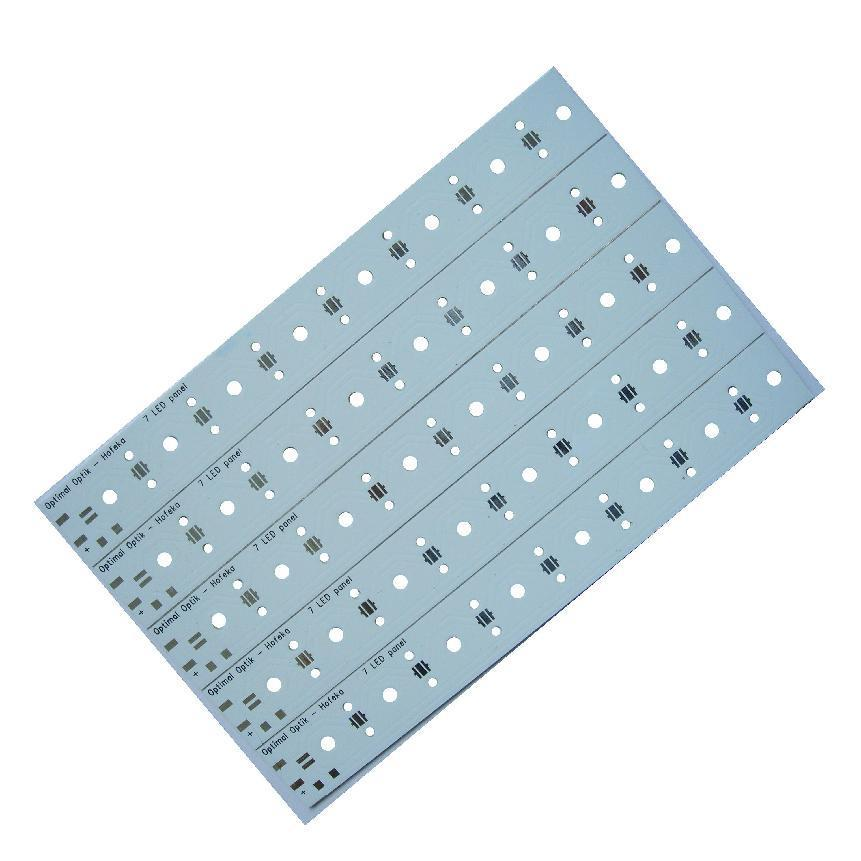

LED PCB Board: Revolutionizing the Lighting IndustryIn today's rapidly evolving technological landscape, the demand for efficient and eco-friendly lighting solutions has never been higher. As the world looks for ways to reduce energy consumption and cut down on harmful emissions, the importance of LED lighting has become increasingly evident. LED PCB boards, in particular, have emerged as a key component in the production of high-quality LED lighting systems.When it comes to manufacturing LED PCB boards, one company comes to mind—{} has been at the forefront of producing innovative and reliable LED PCB boards for a wide range of applications. With a strong focus on research and development, {} has consistently pushed the boundaries of what is possible in the world of LED lighting technology.The company's LED PCB boards are designed to meet the growing demand for energy-efficient and long-lasting lighting solutions. By leveraging cutting-edge manufacturing techniques and materials, {} has been able to deliver products that are not only cost-effective but also environmentally friendly. With a commitment to quality and sustainability, {} has established itself as a leader in the LED lighting industry.One of the key benefits of {}'s LED PCB boards is their versatility. These boards can be customized to meet the specific requirements of different lighting fixtures, allowing for seamless integration and optimal performance. Whether it's for general lighting, automotive applications, or specialty lighting, {} has the expertise and capability to deliver tailored solutions that meet the unique needs of its customers.In addition to their technical prowess, {}'s LED PCB boards are also known for their durability and reliability. With a focus on robust design and stringent quality control, {} ensures that its products meet the highest standards for performance and longevity. This has made {} a trusted partner for companies looking to incorporate LED lighting into their products and projects.Furthermore, {}'s dedication to innovation has resulted in the development of advanced LED PCB board designs that offer enhanced thermal management and compatibility with a wide range of LED modules. This has enabled customers to achieve greater efficiency and performance in their lighting applications, while also reducing maintenance and replacement costs.As the demand for LED lighting continues to grow across various industries, {} remains committed to staying ahead of the curve. The company's investment in research and development has allowed it to continuously improve its LED PCB board offerings, setting new benchmarks for efficiency, reliability, and performance in the industry.Looking ahead, {} is poised to play a pivotal role in driving the adoption of LED lighting solutions on a global scale. By leveraging its expertise and capabilities, {} is well-positioned to address the evolving needs of its customers and contribute to the advancement of sustainable lighting technologies.In conclusion, {}'s LED PCB boards represent a significant advancement in the field of LED lighting technology. With a focus on quality, innovation, and sustainability, {} has established itself as a leading provider of LED PCB boards that are setting new standards for the industry. As the demand for energy-efficient and high-performance lighting solutions continues to rise, {} is well-equipped to meet the needs of its customers and contribute to a brighter, more sustainable future.

Complete Guide to Pcb Smt Process: Everything You Need to Know

In recent technology news, the innovative PCB SMT process is revolutionizing the electronics manufacturing industry. This advanced process, developed and implemented by the industry leader in electronics manufacturing, {}, is setting a new standard for efficiency and quality in PCB assembly.With over 20 years of experience in the industry, {} has been at the forefront of developments in printed circuit board (PCB) manufacturing and surface mount technology (SMT). The company has a strong reputation for delivering high-quality electronic products to a wide range of industries, including automotive, aerospace, telecommunications, and consumer electronics.The PCB SMT process developed by {} is a game-changer in the electronics manufacturing industry. It involves the use of surface mount technology to directly place electronic components onto the surface of a printed circuit board. This process differs from traditional methods, such as through-hole technology, where components are inserted into holes on the circuit board.One of the key advantages of the PCB SMT process is its ability to significantly reduce the size of electronic devices while increasing their functionality and performance. By directly mounting components onto the surface of the PCB, manufacturers can produce smaller, lighter, and more efficient electronic products.Additionally, the PCB SMT process allows for higher component density and greater design flexibility, enabling manufacturers to create more complex and sophisticated electronic devices. This is particularly important in the rapidly evolving technology industry, where consumers are demanding smaller, more powerful, and more feature-rich products.Furthermore, the PCB SMT process offers improved reliability and durability compared to traditional PCB assembly methods. By eliminating the need for holes in the circuit board, the risk of mechanical and electrical failures is reduced, leading to longer-lasting and more robust electronic products.In addition to these benefits, the PCB SMT process also enables faster and more cost-effective production. By streamlining the assembly process and reducing the need for manual labor, manufacturers can significantly reduce lead times and production costs, ultimately making electronic products more affordable for consumers.{}'s expertise and commitment to innovation have positioned the company as a leading provider of PCB SMT solutions. With state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians, {} is able to deliver superior quality products and services to meet the diverse needs of its customers.The company's dedication to research and development has led to the continuous improvement and refinement of the PCB SMT process, ensuring that it remains at the forefront of technological advancements in electronic manufacturing. This commitment to excellence has earned {} a strong reputation as a trusted partner for companies seeking high-quality electronic manufacturing solutions.As the demand for smaller, more powerful, and more reliable electronic products continues to grow, the PCB SMT process developed by {} is poised to play a crucial role in shaping the future of the electronics industry. With its numerous advantages, including increased functionality, improved reliability, and cost-effective production, the PCB SMT process represents a significant advancement in electronic manufacturing technology.In conclusion, the PCB SMT process developed by {} is a groundbreaking innovation that is transforming the way electronic products are designed and manufactured. With its numerous benefits, including smaller size, increased functionality, improved reliability, and cost-effective production, this process is revolutionizing the electronics industry and helping to meet the demands of the ever-evolving technology market. As {} continues to lead the way in electronic manufacturing, its PCB SMT process will undoubtedly play a pivotal role in shaping the future of electronic products.

The Latest News and Developments in Passive Components and Resistors

Passive Components Company Introduces New Line of Resistors{Company Name}, a leading manufacturer of passive components, is excited to announce the launch of their new line of resistors. With a focus on innovation and quality, the company has developed a range of resistors that are designed to meet the evolving needs of the electronics industry.Resistors are essential components in electronic circuits, used to limit the flow of electricity and protect sensitive components from damage. {Company Name}'s new line of resistors offers a variety of options to suit different applications, including precision resistors for high-accuracy circuits, as well as high-power resistors for more demanding environments.One of the key features of {Company Name}'s new resistors is their reliability. The company has utilized state-of-the-art manufacturing processes and rigorous quality control measures to ensure that their resistors meet the highest standards for performance and durability. This commitment to quality is reflected in the company's ISO 9001 certification, which demonstrates their dedication to producing components that consistently meet customer requirements.In addition to their focus on quality, {Company Name} also prioritizes innovation in the development of their resistors. The company's team of engineers and designers are constantly exploring new materials and technologies to improve the performance and efficiency of their components. This dedication to innovation allows {Company Name} to stay ahead of the curve in the rapidly advancing electronics industry, offering customers cutting-edge solutions for their circuit design needs.{Company Name} understands that the electronics industry is constantly evolving, with new technologies and applications driving demand for more advanced components. As a result, the company is committed to offering a comprehensive range of resistors to meet the diverse needs of their customers. Whether it's for consumer electronics, industrial equipment, or automotive applications, {Company Name}'s new line of resistors provides solutions that are tailored to the specific requirements of each application.In addition to their standard range of resistors, {Company Name} also offers custom design services to meet the unique needs of their customers. This allows engineers and designers to collaborate with {Company Name}'s experts to develop resistors that are tailored to their exact specifications, providing a level of flexibility that is unmatched in the industry.As a company with a global presence, {Company Name} is committed to providing excellent customer service and support to their clients around the world. With a network of distributors and sales representatives, {Company Name} is able to offer technical assistance, product information, and logistics support to ensure that customers have access to the components they need, when they need them.{Company Name}'s new line of resistors represents a significant step forward for the company, and a major advancement for the electronics industry as a whole. With their focus on quality, innovation, and customer service, {Company Name} is well positioned to continue leading the way in the development of passive components for years to come.

High Definition Interconnect PCB Fabrication: Everything You Need to Know

HDI PCB Fabrication: A Closer Look at Advanced TechnologyIn today's fast-paced and technology-driven world, the demand for high-density interconnect (HDI) printed circuit boards (PCBs) continues to grow. As a key player in the electronic manufacturing industry, the need for advanced and reliable HDI PCB fabrication solutions has become increasingly important. This is where Company X comes into the picture. Their expertise in providing high-quality, cost-effective, and efficient HDI PCB fabrication services has made them a leader in the field.Company X is a top-notch manufacturer specializing in HDI PCB fabrication, with a proven track record of delivering exceptional products to a wide range of industries, including telecommunications, automotive, medical devices, and consumer electronics. Their state-of-the-art facility is equipped with the latest technology and manufacturing processes to ensure the highest quality and precision in every PCB they produce.With a team of experienced engineers and technicians, Company X is committed to staying at the forefront of innovation in HDI PCB fabrication. Their dedication to research and development has led to the creation of cutting-edge solutions that meet the evolving needs of their clients. By leveraging advanced materials and manufacturing techniques, they are able to produce HDI PCBs with increased functionality, smaller form factors, and improved performance, all while maintaining strict compliance with industry standards and regulations.One of the key factors that sets Company X apart from the competition is their ability to offer a comprehensive range of HDI PCB fabrication services, including PCB design, assembly, and testing. This full suite of offerings allows their clients to streamline their production processes and ensures that their PCBs are manufactured with the utmost care and attention to detail.Furthermore, Company X places a strong emphasis on quality control throughout the entire fabrication process. Their rigorous inspection and testing procedures guarantee that every HDI PCB meets the highest standards for reliability, durability, and performance. This commitment to quality has earned them the trust and loyalty of their customers, who rely on Company X to deliver superior products that consistently exceed their expectations.In addition to their technical expertise, Company X takes great pride in their customer-centric approach. They understand that every client has unique requirements and work closely with them to develop customized solutions that address their specific needs. Whether it's a prototype for a new product or a large-scale production run, Company X is dedicated to delivering results that align with their clients' goals and objectives.Looking ahead, Company X remains focused on staying ahead of the curve in HDI PCB fabrication. They continue to invest in research and development to explore new materials, processes, and technologies that will further enhance the performance and capabilities of their PCBs. By taking a proactive approach to innovation, they strive to be at the forefront of industry trends and deliver value-added solutions that give their clients a competitive edge in their respective markets.As the demand for smaller, faster, and more complex electronic devices continues to grow, the need for reliable and efficient HDI PCB fabrication will only become more critical. Company X is well positioned to meet these evolving demands with their unwavering commitment to excellence and their ability to push the boundaries of what is possible in HDI PCB fabrication. With a solid reputation for delivering top-tier products and a dedication to continuous improvement, Company X is poised to remain a trusted partner for companies seeking high-quality HDI PCB fabrication solutions.

Benefits of Active Circuit Elements in Electronic Devices

. (active circuit elements) Unveils New Technology for Enhanced Circuit Performance[Company Name], a leading provider of innovative electronic products, has announced the release of a groundbreaking new technology in the field of active circuit elements. This cutting-edge technology promises to revolutionize the way circuits are designed and will significantly improve overall performance.The new technology, developed by [Company Name]'s team of expert engineers, focuses on enhancing the functionality of active circuit elements such as transistors and diodes. By incorporating advanced materials and novel design strategies, [Company Name] has been able to push the boundaries of circuit performance to new heights.One of the key features of this new technology is its ability to significantly reduce power consumption without compromising on performance. This is a critical factor in today's electronic devices, where power efficiency is paramount. With [Company Name]'s technology, circuit designers can achieve substantial power savings, leading to longer battery life and reduced energy consumption.In addition to improved power efficiency, the new technology also offers enhanced speed and reliability. By optimizing the properties of active circuit elements, [Company Name] has succeeded in creating circuits that operate at higher speeds and are more robust against environmental fluctuations. This is particularly important in applications such as telecommunications, where fast and reliable circuit performance is essential.Moreover, [Company Name] has ensured that its new technology is highly versatile and can be easily integrated into existing circuit designs. This means that circuit designers can take advantage of the improved performance benefits without having to completely overhaul their current designs. This seamless integration capability will enable rapid adoption of the technology across a wide range of industries.In a statement regarding the new technology, [Company Name]'s CEO expressed enthusiasm about the potential impact it will have on the electronics industry. "We are proud to introduce this breakthrough technology in active circuit elements," said the CEO. "We believe that it will drive significant advancements in circuit design and enable the development of more efficient and reliable electronic devices."The unveiling of this new technology further solidifies [Company Name]'s position as a trailblazer in the field of electronic innovation. With a strong track record of delivering cutting-edge solutions, the company is widely recognized for its commitment to pushing the boundaries of what is possible in electronics.[Company Name] has already begun collaborating with leading electronics manufacturers to integrate the new technology into upcoming products. This strategic partnership approach will ensure that the benefits of the technology are widely accessible to consumers and will help drive its adoption across the industry.As the electronic landscape continues to evolve, [Company Name] remains dedicated to staying at the forefront of technological advancement. With the introduction of this new active circuit element technology, the company is poised to make a significant impact on the future of electronic design and performance. Industry experts and consumers alike are eagerly anticipating the potential of this groundbreaking technology, which promises to set a new standard for circuit performance.