High Definition Interconnect PCB Fabrication: Everything You Need to Know

By:Admin

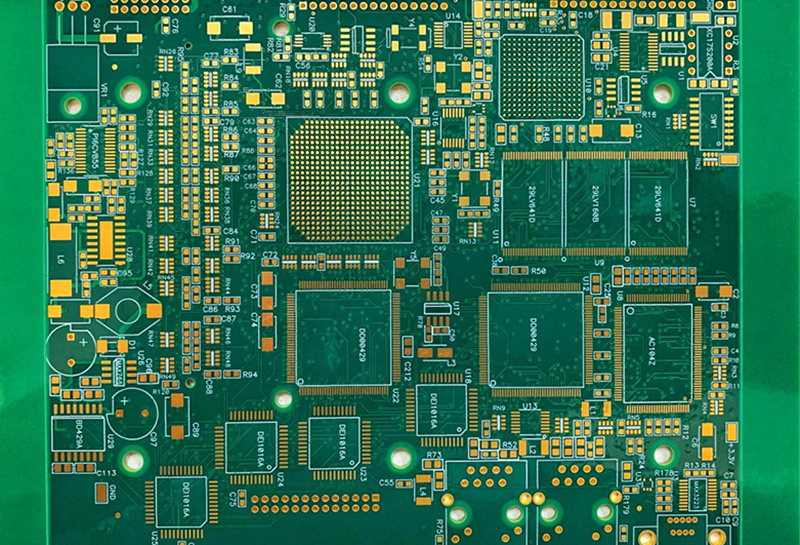

In today's fast-paced and technology-driven world, the demand for high-density interconnect (HDI) printed circuit boards (PCBs) continues to grow. As a key player in the electronic manufacturing industry, the need for advanced and reliable HDI PCB fabrication solutions has become increasingly important. This is where Company X comes into the picture. Their expertise in providing high-quality, cost-effective, and efficient HDI PCB fabrication services has made them a leader in the field.

Company X is a top-notch manufacturer specializing in HDI PCB fabrication, with a proven track record of delivering exceptional products to a wide range of industries, including telecommunications, automotive, medical devices, and consumer electronics. Their state-of-the-art facility is equipped with the latest technology and manufacturing processes to ensure the highest quality and precision in every PCB they produce.

With a team of experienced engineers and technicians, Company X is committed to staying at the forefront of innovation in HDI PCB fabrication. Their dedication to research and development has led to the creation of cutting-edge solutions that meet the evolving needs of their clients. By leveraging advanced materials and manufacturing techniques, they are able to produce HDI PCBs with increased functionality, smaller form factors, and improved performance, all while maintaining strict compliance with industry standards and regulations.

One of the key factors that sets Company X apart from the competition is their ability to offer a comprehensive range of HDI PCB fabrication services, including PCB design, assembly, and testing. This full suite of offerings allows their clients to streamline their production processes and ensures that their PCBs are manufactured with the utmost care and attention to detail.

Furthermore, Company X places a strong emphasis on quality control throughout the entire fabrication process. Their rigorous inspection and testing procedures guarantee that every HDI PCB meets the highest standards for reliability, durability, and performance. This commitment to quality has earned them the trust and loyalty of their customers, who rely on Company X to deliver superior products that consistently exceed their expectations.

In addition to their technical expertise, Company X takes great pride in their customer-centric approach. They understand that every client has unique requirements and work closely with them to develop customized solutions that address their specific needs. Whether it's a prototype for a new product or a large-scale production run, Company X is dedicated to delivering results that align with their clients' goals and objectives.

Looking ahead, Company X remains focused on staying ahead of the curve in HDI PCB fabrication. They continue to invest in research and development to explore new materials, processes, and technologies that will further enhance the performance and capabilities of their PCBs. By taking a proactive approach to innovation, they strive to be at the forefront of industry trends and deliver value-added solutions that give their clients a competitive edge in their respective markets.

As the demand for smaller, faster, and more complex electronic devices continues to grow, the need for reliable and efficient HDI PCB fabrication will only become more critical. Company X is well positioned to meet these evolving demands with their unwavering commitment to excellence and their ability to push the boundaries of what is possible in HDI PCB fabrication. With a solid reputation for delivering top-tier products and a dedication to continuous improvement, Company X is poised to remain a trusted partner for companies seeking high-quality HDI PCB fabrication solutions.

Company News & Blog

How to Flash PCBA: A Step-by-Step Guide

Pcba Flashing, a leading provider of printed circuit board assembly (PCBA) solutions, has announced the release of a new and innovative product that aims to revolutionize the electronics industry. With over 20 years of experience in the field, Pcba Flashing has established itself as a trusted partner for businesses looking to create high-quality electronic products.The newly developed product, which is set to be released in the coming months, promises to offer faster and more reliable flash programming for PCBAs. This breakthrough technology will significantly reduce production time and costs, providing manufacturers with a competitive edge in the market.This latest development is a testament to Pcba Flashing's commitment to innovation and dedication to meeting the evolving needs of the electronics industry. The company has a proven track record of delivering cutting-edge solutions that enhance the performance and reliability of electronic products.Pcba Flashing's state-of-the-art manufacturing facilities are equipped with the latest technology and equipment, allowing the company to produce PCBAs that meet the highest quality standards. With a team of experienced engineers and technicians, Pcba Flashing has the expertise to develop custom solutions tailored to the specific requirements of its clients.In addition to its technical capabilities, Pcba Flashing is also known for its exceptional customer service. The company takes pride in building strong and long-lasting relationships with its clients, providing them with support and guidance throughout the product development and manufacturing process."We are thrilled to introduce this new product to the market," said [Company Spokesperson], [Title] at Pcba Flashing. "We believe that it will have a significant impact on the way PCBAs are programmed, offering our clients a more efficient and cost-effective solution."Pcba Flashing's dedication to innovation and quality has earned the company a stellar reputation in the industry. With a focus on continuous improvement and a commitment to excellence, Pcba Flashing is well-positioned to remain a leader in the rapidly evolving electronics market.As the demand for electronic products continues to grow, Pcba Flashing is poised to play a key role in supporting businesses looking to develop cutting-edge solutions. With its advanced technology, expertise, and commitment to customer satisfaction, Pcba Flashing is undoubtedly a company to watch in the coming years.In conclusion, Pcba Flashing's latest product release is a testament to the company's dedication to innovation and excellence. With its advanced technology, experienced team, and commitment to customer satisfaction, Pcba Flashing is well-positioned to continue leading the way in the electronics industry.

The Latest News and Developments in Passive Components and Resistors

Passive Components Company Introduces New Line of Resistors{Company Name}, a leading manufacturer of passive components, is excited to announce the launch of their new line of resistors. With a focus on innovation and quality, the company has developed a range of resistors that are designed to meet the evolving needs of the electronics industry.Resistors are essential components in electronic circuits, used to limit the flow of electricity and protect sensitive components from damage. {Company Name}'s new line of resistors offers a variety of options to suit different applications, including precision resistors for high-accuracy circuits, as well as high-power resistors for more demanding environments.One of the key features of {Company Name}'s new resistors is their reliability. The company has utilized state-of-the-art manufacturing processes and rigorous quality control measures to ensure that their resistors meet the highest standards for performance and durability. This commitment to quality is reflected in the company's ISO 9001 certification, which demonstrates their dedication to producing components that consistently meet customer requirements.In addition to their focus on quality, {Company Name} also prioritizes innovation in the development of their resistors. The company's team of engineers and designers are constantly exploring new materials and technologies to improve the performance and efficiency of their components. This dedication to innovation allows {Company Name} to stay ahead of the curve in the rapidly advancing electronics industry, offering customers cutting-edge solutions for their circuit design needs.{Company Name} understands that the electronics industry is constantly evolving, with new technologies and applications driving demand for more advanced components. As a result, the company is committed to offering a comprehensive range of resistors to meet the diverse needs of their customers. Whether it's for consumer electronics, industrial equipment, or automotive applications, {Company Name}'s new line of resistors provides solutions that are tailored to the specific requirements of each application.In addition to their standard range of resistors, {Company Name} also offers custom design services to meet the unique needs of their customers. This allows engineers and designers to collaborate with {Company Name}'s experts to develop resistors that are tailored to their exact specifications, providing a level of flexibility that is unmatched in the industry.As a company with a global presence, {Company Name} is committed to providing excellent customer service and support to their clients around the world. With a network of distributors and sales representatives, {Company Name} is able to offer technical assistance, product information, and logistics support to ensure that customers have access to the components they need, when they need them.{Company Name}'s new line of resistors represents a significant step forward for the company, and a major advancement for the electronics industry as a whole. With their focus on quality, innovation, and customer service, {Company Name} is well positioned to continue leading the way in the development of passive components for years to come.

Innovative Rigid Flex Technology: Advantages and Applications

Rigid flex PCBs (printed circuit boards) have been gaining popularity in the electronics industry due to their ability to combine the benefits of both rigid and flexible PCBs. This innovative technology is being adopted by various industries, from consumer electronics to medical devices, and its demand is expected to grow in the coming years.Rigid flex PCBs are a type of circuit board that combines flexible PCBs with rigid PCBs, allowing for more complex and versatile designs. They are made from a combination of flexible substrate material and rigid laminate material, allowing them to bend and fold in ways that traditional rigid PCBs cannot. This flexibility opens up new possibilities for product design and allows for more compact and lightweight electronic devices.One company at the forefront of the rigid flex PCB industry is {}. With over 20 years of experience in the PCB manufacturing industry, {} has established itself as a leading provider of high-quality PCBs for a wide range of applications. The company's expertise in rigid flex PCBs has allowed them to stay ahead of the curve and meet the growing demand for this innovative technology.{}'s state-of-the-art manufacturing facilities and advanced technology allow them to produce rigid flex PCBs with high precision and reliability. Their team of experienced engineers and technicians works closely with clients to understand their specific requirements and provide customized solutions to meet their needs. Whether it's for aerospace, automotive, medical, or consumer electronics, {} has the capabilities to deliver top-notch rigid flex PCBs for any industry.One of the key advantages of rigid flex PCBs is their ability to reduce the overall size and weight of electronic devices. By eliminating the need for connectors and cables, rigid flex PCBs enable more compact and lightweight designs, making them ideal for portable and wearable electronics. This can lead to cost savings in production and improved performance in the final product.In addition to size and weight savings, rigid flex PCBs also offer improved reliability and durability. The elimination of connectors and cables reduces the risk of mechanical failure and signal interference, resulting in more reliable and robust electronic devices. This is particularly important in industries such as aerospace and medical, where failure is not an option.The versatility of rigid flex PCBs also allows for more complex and creative product designs. Their ability to bend and fold opens up new possibilities for innovative and ergonomic designs, giving engineers and designers more freedom to create unique and compelling products. This can lead to a competitive edge in the market and enhance the overall user experience.With the increasing demand for smaller, lighter, and more reliable electronic devices, the market for rigid flex PCBs is expected to continue growing in the coming years. Companies like {} are well-positioned to meet this demand with their advanced manufacturing capabilities and expertise in rigid flex PCB technology.As the electronics industry continues to evolve, rigid flex PCBs will play a crucial role in enabling new and exciting innovations. With their ability to combine the benefits of both rigid and flexible PCBs, they offer a compelling solution for a wide range of applications. As more companies and industries recognize the advantages of rigid flex PCBs, their adoption is expected to become more widespread, driving further growth and advancement in the electronics industry.

How to Perform a DC Voltage Test: Step-by-Step Guide

The importance of conducting comprehensive DC voltage tests cannot be overstated, and with the latest technological advancements in the field, it is easier than ever to ensure the safety and reliability of electrical systems. DC voltage testing is a critical aspect of maintenance, troubleshooting, and quality control for a wide range of industries, from power generation and distribution to manufacturing and telecommunications. It is essential for identifying potential issues such as insulation breakdown, voltage drops, and other electrical faults that can lead to costly downtime and safety hazards.One company that has been at the forefront of developing innovative DC voltage testing solutions is {}. With a strong commitment to research and development, they have introduced a range of advanced testing equipment that has set new standards for accuracy, efficiency, and user-friendliness. Their cutting-edge products have been widely adopted by professionals in various industries, earning a reputation for reliability and precision.The company's flagship DC voltage testing equipment offers a wide range of features that set it apart from traditional testing methods. For instance, their latest model is equipped with advanced digital technology, allowing for precise measurement and analysis of voltage levels. This ensures that potential issues are identified with high accuracy, providing valuable insights for maintenance and troubleshooting purposes.In addition to accuracy, the company's testing equipment is designed with user convenience in mind. The intuitive interface and ergonomic design make it easy for technicians to operate the equipment, even in challenging environments. This not only improves efficiency but also minimizes the risk of errors, ensuring that testing procedures are carried out smoothly and effectively.Furthermore, the company is dedicated to providing comprehensive support for their products, including extensive training programs and technical assistance. This commitment to customer satisfaction has made them a trusted partner for businesses looking to elevate their DC voltage testing capabilities.With a strong focus on innovation and quality, {} has earned a prominent position in the market, serving a wide range of industries with their state-of-the-art testing solutions. Their dedication to advancing DC voltage testing technology has not only elevated industry standards but has also contributed to improved safety and reliability for countless electrical systems.In conclusion, the importance of DC voltage testing cannot be overlooked, and {} is at the forefront of delivering cutting-edge solutions that empower businesses to ensure the safety and reliability of their electrical systems. With a strong focus on innovation, quality, and customer satisfaction, they continue to set new benchmarks for DC voltage testing, contributing to the advancement of various industries and the protection of critical electrical infrastructure.Whether it's for maintenance, troubleshooting, or quality control, businesses can rely on {} to provide the most advanced and reliable DC voltage testing solutions. With their commitment to excellence, they are poised to shape the future of this vital aspect of electrical system management.

How Printed Circuit Assemblies are Changing the Electronics Manufacturing Industry

Printed Circuit Assy, also known as PCB assembly, is a critical part of the electronics manufacturing process. It involves assembling various electronic components onto a printed circuit board to create a functional electronic device. From simple consumer electronics to complex industrial machinery, PCB assembly is an integral part of the production process.Founded in 1990, and with over three decades of experience, our company has been a leading provider of PCB assembly services for a wide range of industries. With state-of-the-art facilities and a team of skilled professionals, we are committed to delivering high-quality PCB assemblies that meet the specific requirements of our clients.Our company offers a comprehensive range of PCB assembly services, including surface-mount technology (SMT) assembly, through-hole assembly, and mixed-technology assembly. Our advanced manufacturing capabilities allow us to handle complex PCB designs and produce high-quality assemblies with tight tolerances.In addition to our assembly services, we also provide comprehensive testing and inspection services to ensure the quality and reliability of our PCB assemblies. With advanced testing equipment and strict quality control processes, we are able to detect and rectify any potential defects or issues before the final products are delivered to our clients.One of the key strengths of our company is our ability to provide customized PCB assembly solutions to meet the specific needs of our clients. We work closely with our customers to understand their requirements and provide tailored assembly solutions that align with their design specifications, budget, and timeline.Over the years, our company has built a strong reputation for delivering high-quality PCB assemblies with exceptional reliability and performance. We have successfully served clients in various industries, including telecommunications, automotive, aerospace, medical, and consumer electronics.As a customer-centric company, we are committed to providing excellent service and support to our clients throughout the entire PCB assembly process. From initial design and prototyping to mass production and after-sales support, we work closely with our clients to ensure a seamless and efficient experience.In line with the ever-evolving nature of the electronics industry, our company continuously invests in the latest technology and equipment to enhance our manufacturing capabilities. We stay abreast of the latest industry trends and standards to deliver cutting-edge PCB assembly solutions that meet the demands of modern electronics applications.In addition to our commitment to quality and innovation, our company places a strong emphasis on environmental sustainability and social responsibility. We adhere to strict environmental regulations and promote eco-friendly practices in our manufacturing processes. Furthermore, we prioritize the well-being and safety of our employees, providing a conducive and inclusive work environment.Looking ahead, our company remains focused on driving technological advancements and delivering superior PCB assembly solutions to our clients. With a dedication to excellence and a passion for innovation, we are well-positioned to meet the evolving needs of the electronics industry and continue to be a trusted partner for our clients.In conclusion, Printed Circuit Assembly is a critical component of the electronics manufacturing process, and our company has established itself as a leading provider of high-quality PCB assembly services. With a strong focus on quality, innovation, and customer satisfaction, we are committed to delivering customized assembly solutions that meet the specific requirements of our clients. As we continue to invest in technology and expand our capabilities, we are poised to remain at the forefront of the PCB assembly industry.

Optimize Your Production Line with Automated PCB Testing

Automated PCB Testing Revolutionizes Quality Control at {}In the era of advanced technology and fast-paced production processes, the need for efficient quality control has become more crucial than ever. With the increasing complexity of electronic components, the demand for reliable and accurate testing methods has surged. One company that has truly embraced this challenge is {}.Based in the heart of the electronic manufacturing hub, {} has been a key player in providing cutting-edge solutions for the printed circuit board (PCB) industry. With a strong commitment to innovation and precision, the company has recently introduced an automated PCB testing system that is set to revolutionize the quality control process.The automated PCB testing system developed by {} represents a significant advancement in the industry. By combining state-of-the-art technology with a deep understanding of the challenges faced by electronic manufacturers, {} has created a solution that promises to streamline the testing process and deliver superior results.Traditionally, PCB testing has been a time-consuming and labor-intensive task, often prone to errors and inconsistencies. Manual testing methods are not only slow and inefficient, but also leave room for human error, leading to potential defects slipping through the cracks. {}'s automated testing system addresses these issues by offering a seamless and reliable testing process that ensures the highest level of quality control.One of the key features of {}'s automated PCB testing system is its ability to detect defects with unmatched precision. Equipped with advanced sensors and intelligent algorithms, the system is capable of identifying even the smallest imperfections in PCBs, ensuring that only the highest quality products make it to the market. This level of accuracy not only enhances the overall quality control process but also helps to minimize the risk of product recalls and costly rework.Moreover, the automated testing system significantly reduces the time and resources required for testing. By automating the process, {} has managed to greatly increase efficiency and throughput, enabling manufacturers to meet tight production deadlines without compromising on quality. This is particularly crucial in today's fast-paced manufacturing environment, where time-to-market is a critical factor in staying competitive.In addition to its technical capabilities, {}'s automated PCB testing system is designed with user-friendliness in mind. The intuitive interface and easy-to-use controls make it accessible to operators of all levels of expertise, eliminating the need for extensive training and reducing the likelihood of operator error. This ensures that the system can be seamlessly integrated into existing production lines without causing disruptions or delays.Furthermore, {} provides comprehensive technical support and training to its clients, ensuring that they can maximize the benefits of the automated testing system. With a team of experienced engineers and technical experts, the company is committed to assisting its customers in optimizing their testing processes and achieving the best possible outcomes.The introduction of {}'s automated PCB testing system marks a significant milestone in the evolution of quality control in the electronic manufacturing industry. By leveraging the power of automation and advanced technology, {} has set a new standard for PCB testing, offering a solution that is not only more accurate and efficient but also more accessible and user-friendly.As the demand for high-quality electronic components continues to grow, the importance of reliable and efficient testing methods cannot be overstated. With its automated PCB testing system, {} has positioned itself as a leader in providing innovative solutions that address the key challenges faced by manufacturers, ultimately contributing to the advancement of the electronics industry as a whole.

Top tips for low volume PCB fabrication

Low Volume PCB Fabrication Made Easy with [Company Name]In today's fast-paced and technology-driven world, printed circuit boards (PCBs) play a crucial role in the functioning of various electronic devices. Whether it's a small handheld gadget or a complex industrial machinery, PCBs are at the heart of these electronic devices. However, for companies looking to produce low volumes of PCBs, finding a reliable and cost-effective fabrication solution can be a daunting task. This is where [Company Name] comes in, offering a seamless and efficient solution for low volume PCB fabrication.[Company Name] is a leading provider of PCB fabrication services, specializing in catering to the needs of small and medium-sized businesses that require low volumes of PCBs. With years of experience and expertise in the field, [Company Name] has established itself as a trusted partner for businesses looking for high-quality PCB fabrication without the high volume requirements typically demanded by other manufacturers.One of the key advantages of working with [Company Name] is their ability to provide customized solutions for low volume PCB fabrication. While many manufacturers prioritize large-scale production runs, [Company Name] understands the unique requirements of small and medium-sized businesses. They are able to provide personalized attention to each project, ensuring that the specific needs of their clients are met with precision and accuracy.In addition to customization, [Company Name] also offers a quick turnaround time for low volume PCB fabrication. Their streamlined production process, combined with state-of-the-art technology and machinery, allows them to efficiently fulfill orders without compromising on quality. This is a significant advantage for businesses that require a fast and reliable solution for their PCB fabrication needs.Furthermore, [Company Name] is committed to maintaining the highest standards of quality in their fabrication processes. They adhere to strict quality control measures at every step of the production cycle, ensuring that each PCB meets the exact specifications and performance standards required by their clients. This dedication to quality has earned [Company Name] a reputation for excellence in the industry, making them a preferred choice for businesses seeking reliable low volume PCB fabrication services.Another standout feature of [Company Name]'s services is their cost-effective pricing structure for low volume PCB fabrication. As a business-focused service provider, [Company Name] understands the importance of balancing quality and affordability. They have developed a pricing model that allows small and medium-sized businesses to access high-quality PCB fabrication services without breaking the bank. This makes [Company Name] an ideal partner for businesses looking to optimize their production costs while maintaining top-notch quality.Moreover, [Company Name] offers comprehensive support and guidance throughout the entire fabrication process. Their team of experienced professionals works closely with clients to understand their specific requirements and provide expert advice and recommendations. From initial design consultations to final product delivery, [Company Name] ensures that their clients are supported at every step, minimizing the complexities often associated with PCB fabrication.With [Company Name]'s low volume PCB fabrication services, businesses can enjoy a hassle-free and efficient solution for their PCB production needs. Whether it's a prototype for a new product or a small-scale production run, [Company Name] is dedicated to delivering the highest quality PCBs to meet the unique requirements of their clients.In conclusion, [Company Name] is revolutionizing the landscape of low volume PCB fabrication with their commitment to quality, affordability, and personalized service. Businesses looking for a reliable and efficient solution for their PCB fabrication needs can confidently turn to [Company Name] for a seamless and hassle-free experience. With their expertise and dedication to excellence, [Company Name] is poised to continue leading the way in low volume PCB fabrication, empowering businesses to bring their electronic innovations to life.

How to Design a Circuit Card Assembly: A Complete Guide

Circuit Card Assembly Design is an important process in the manufacturing of electronic devices and systems. It involves the design and assembly of circuit boards that serve as the foundation for the functionality of a wide range of products, from smartphones to medical devices.One company that is known for its expertise in circuit card assembly design is {}. With a strong focus on innovation and quality, {} has established itself as a leading provider of circuit card assembly design services for a diverse range of industries.Founded in {}, {} has built a reputation for excellence in circuit card assembly design through its commitment to staying at the forefront of technological advancements. The company's team of experienced engineers and designers are dedicated to ensuring that each circuit card assembly is optimized for performance, reliability, and cost-effectiveness.One of the key strengths of {} is its ability to provide customized circuit card assembly design solutions to meet the specific needs of its clients. Whether it's a complex multi-layered circuit board for a high-tech consumer electronics product or a simple single-layer board for a basic control system, {} has the expertise and experience to deliver high-quality designs that meet and exceed client expectations.In addition to its superior design capabilities, {} also prides itself on its commitment to quality and reliability. The company utilizes advanced testing and inspection processes to ensure that each circuit card assembly meets the highest standards for performance and durability. This dedication to quality has earned {} the trust and loyalty of its clients, who rely on the company to deliver circuit card assembly designs that are of the highest caliber.As technology continues to advance at a rapid pace, the demand for innovative and high-performance circuit card assembly designs is only expected to grow. {} is poised to meet this demand with its ongoing investment in research and development, as well as its dedication to staying ahead of industry trends.With a proven track record of delivering exceptional circuit card assembly design services, {} is well-positioned to continue its leadership in the field. The company's commitment to innovation, quality, and customer satisfaction sets it apart as a trusted partner for businesses looking to develop cutting-edge electronic products.In conclusion, the design and assembly of circuit cards is a critical process in the production of electronic devices, and companies like {} play a vital role in ensuring that these products meet the highest standards for performance and reliability. With its expertise, commitment to quality, and dedication to innovation, {} is well-equipped to meet the evolving needs of the electronics industry and continue to be a leader in circuit card assembly design.

How to Perform a DC Voltage Check with a Multimeter

The use of a multimeter for checking direct current (DC) voltage has become increasingly popular in various industries. With the advancement of technology, multimeters have become an essential tool for measuring and testing electrical circuits and components. The accuracy and reliability of a multimeter make it an indispensable instrument for electricians, engineers, and technicians. The ability to measure DC voltage is crucial for troubleshooting and diagnosing electrical systems, as well as for ensuring the safety and efficiency of electrical equipment.{Company Name} is a leading manufacturer of high-quality multimeters that are known for their accuracy, durability, and reliability. With a strong commitment to innovation and quality, {Company Name} has been at the forefront of developing advanced multimeters that meet the needs of professionals in various industries. The company's multimeters are designed to provide accurate measurements, user-friendly interface, and robust construction to withstand the rigors of everyday use.The DC voltage check feature in {Company Name}'s multimeters allows users to accurately measure the voltage in a DC circuit. This is essential for identifying electrical issues, troubleshooting problems, and ensuring the proper functioning of electrical systems. The multimeters are equipped with precise measurement capabilities, ensuring that users can obtain accurate voltage readings for their specific applications. With a wide range of voltage measurement options, {Company Name}'s multimeters are suitable for a variety of DC voltage testing requirements.One of the key advantages of using {Company Name}'s multimeters for DC voltage check is the reliability and accuracy of the measurements. The multimeters are equipped with high-quality components and advanced technology that ensure precise voltage readings, allowing users to make informed decisions about the condition of the electrical systems they are testing. This level of accuracy is crucial for preventing potential electrical hazards and maintaining the efficiency of electrical equipment.Furthermore, {Company Name}'s multimeters are designed with user convenience in mind, featuring easy-to-read displays, intuitive controls, and ergonomic designs. This makes them suitable for both experienced professionals and individuals who are new to electrical testing. The user-friendly interface enhances the overall testing experience, allowing users to perform DC voltage checks with ease and confidence.In addition to the reliability and user-friendly features, {Company Name}'s multimeters are built to withstand the demands of various work environments. They are constructed with durable materials and are tested to ensure their resilience to extreme conditions. This makes them suitable for use in industrial settings, construction sites, and other challenging work environments where reliable electrical testing tools are essential.With a commitment to quality and innovation, {Company Name} continues to develop multimeters that meet the evolving needs of professionals in the electrical industry. The company's dedication to excellence has made it a trusted provider of reliable and accurate electrical testing instruments.In conclusion, the DC voltage check feature in {Company Name}'s multimeters provides professionals with a reliable and accurate tool for measuring and testing DC voltage in electrical circuits and components. With a focus on precision, durability, and user convenience, {Company Name} is committed to providing high-quality multimeters that meet the demanding requirements of various industries. Whether it is for troubleshooting electrical issues, inspecting equipment, or maintaining electrical systems, {Company Name}'s multimeters are the go-to choice for professionals who require precision and reliability in their electrical testing tools.

Top Tips for Using an Empty PCB Board

[Company Logo][Company Name][Company Address][City, State, Zip Code][Phone Number][Email Address][Website URL]For Immediate ReleaseEmpty PCB Board: The Latest Innovation from [Company Name][City, State, Date] - [Company Name], a leading manufacturer of electronic components, has recently announced the release of their latest innovation, the Empty PCB Board. This cutting-edge technology is designed to revolutionize the electronic manufacturing industry, providing companies with a cost-effective solution for their PCB assembly needs.The Empty PCB Board, also known as a bare board or unpopulated PCB, is a printed circuit board that comes without any electronic components attached to it. This allows companies to customize their PCB assembly according to their specific requirements, without being limited by pre-installed components. The Empty PCB Board is available in various sizes, shapes, and materials, making it suitable for a wide range of electronic applications.[Company Name] has been a key player in the electronic manufacturing industry for over [number] years. With their state-of-the-art facilities and cutting-edge technologies, the company has gained a reputation for delivering high-quality products and exceptional customer service. The release of the Empty PCB Board is yet another testament to their commitment to innovation and excellence."We are thrilled to introduce the Empty PCB Board to the market," said [Spokesperson's Name], [Job Title] at [Company Name]. "This product is the result of extensive research and development, and we believe it will significantly impact the way companies approach their PCB assembly process. The versatility and flexibility of the Empty PCB Board make it an ideal choice for companies looking to streamline their production and reduce costs."The Empty PCB Board offers several advantages for electronic manufacturers. By customizing the assembly process, companies can optimize the design and performance of their electronic products. This flexibility also allows for easier troubleshooting and repair, as components can be easily replaced or upgraded as needed. Additionally, the Empty PCB Board reduces the lead time for PCB assembly, as companies can keep a stock of bare boards and populate them on-demand.In addition to the Empty PCB Board, [Company Name] offers a comprehensive range of electronic components and services, including PCB assembly, component sourcing, and prototype development. The company's team of experts provides technical support and guidance throughout the entire manufacturing process, ensuring that customers receive the best solutions for their electronic needs.With the release of the Empty PCB Board, [Company Name] aims to further solidify its position as a leader in the electronic manufacturing industry. The company continues to invest in research and development, as well as strategic partnerships, to bring innovative products and services to the market.For more information about the Empty PCB Board and other products and services offered by [Company Name], please visit their website at [Company Website].About [Company Name]:[Company Name] is a leading manufacturer of electronic components, providing high-quality products and exceptional service to customers worldwide. With a focus on innovation and excellence, the company offers a comprehensive range of electronic solutions, including PCB assembly, component sourcing, and prototype development. With a commitment to customer satisfaction, [Company Name] continues to set new standards in the electronic manufacturing industry.Contact:[Contact Person's Name][Contact Person's Job Title][Company Name][Phone Number][Email Address][Company Website]###[Note to Editor: Please replace the placeholders with the actual information before publishing the news.]