New Water-Proof PCBA Technology Provides Enhanced Durability

By:Admin

In today's digital world, electronic devices have become an integral part of our daily lives. From smartphones to smartwatches, we rely on these devices for communication, entertainment, and information. However, one of the biggest challenges faced by electronic devices is their vulnerability to water damage. Water can cause irreparable damage to the printed circuit board assembly (PCBA) of these devices, rendering them useless. In response to this issue, [Company Name], a leading provider of electronic solutions, has introduced a revolutionary water-proof PCBA that is set to change the game for electronic devices.

With over [number] years of experience in the electronic industry, [Company Name] has established itself as a pioneer in developing innovative solutions for electronic devices. The company has a team of highly skilled engineers and technicians who are constantly working on improving the performance and durability of electronic components. Their latest creation, the water-proof PCBA, is a testament to their commitment to innovation and excellence.

The water-proof PCBA is designed to withstand exposure to water and moisture, making it ideal for a wide range of electronic devices. Whether it's a smartphone, tablet, or wearable device, the water-proof PCBA ensures that the electronic components remain protected from water damage. This innovation is a game-changer for industries such as healthcare, sports, and outdoor activities, where electronic devices are constantly exposed to water and moisture.

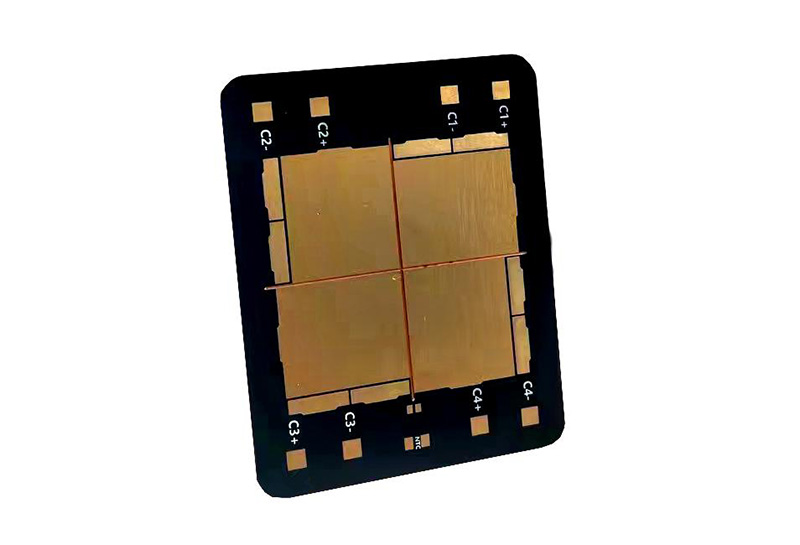

One of the key features of the water-proof PCBA is its advanced coating technology, which creates a protective barrier around the electronic components. This coating is designed to repel water and prevent it from seeping into the circuit board, thus safeguarding the integrity of the device. Additionally, the water-proof PCBA undergoes rigorous testing to ensure that it meets the highest standards of durability and performance.

The development of the water-proof PCBA is a result of [Company Name]'s commitment to research and development. The company invests heavily in R&D to stay ahead of the curve and anticipate the needs of the ever-evolving electronic industry. By partnering with leading material suppliers and industry experts, [Company Name] has been able to develop a cutting-edge solution that addresses a critical issue in the electronic devices market.

Moreover, [Company Name] is dedicated to sustainability and reducing its environmental impact. The water-proof PCBA is manufactured using environmentally-friendly materials and processes, ensuring that it aligns with the company's green initiatives. This commitment to sustainability sets [Company Name] apart from its competitors and demonstrates its ethical approach to business.

The introduction of the water-proof PCBA has the potential to revolutionize the electronic devices market. With its ability to protect electronic components from water damage, it opens up new possibilities for the design and functionality of electronic devices. Manufacturers and consumers alike are set to benefit from this innovative solution, as it offers peace of mind and confidence in the durability of electronic devices.

In conclusion, [Company Name]'s water-proof PCBA represents a significant advancement in the field of electronic devices. Its ability to protect electronic components from water damage and moisture opens up new opportunities for the industry. With its commitment to innovation, excellence, and sustainability, [Company Name] continues to lead the way in shaping the future of electronic devices. The water-proof PCBA is a testament to the company's dedication to pushing boundaries and creating solutions that make a real difference in the world of electronics.

Company News & Blog

Top Tips for Outdoor Displaying PCBs: What to Know

Outdoor Displaying PCB: A Booming IndustryOutdoor displaying PCB (printed circuit board) has become an integral part of the signage and outdoor advertising industry. These PCBs are used to power and control various outdoor display systems such as electronic billboards, digital signage, and LED screens. With the rise of digital advertising, the demand for high-quality outdoor displaying PCBs has seen a significant increase in recent years. In response to this growing demand, companies like {} have been at the forefront of developing cutting-edge outdoor displaying PCB technologies.{} is a leading manufacturer and supplier of outdoor displaying PCBs. With over 20 years of experience in the industry, the company has established itself as a trusted partner for businesses looking to enhance their outdoor advertising and signage solutions. {} offers a wide range of outdoor displaying PCB products, including single and double-sided PCBs, multi-layer PCBs, and flexible PCBs, to meet the diverse needs of their customers.The outdoor displaying PCB industry has seen rapid technological advancements in recent years, driven by the increasing demand for energy-efficient and high-definition outdoor display systems. {} has been at the forefront of these developments, continuously innovating its product offerings to meet the evolving needs of the market. The company has invested heavily in research and development to create PCBs that are not only robust and reliable but also capable of delivering stunning visual performance in various outdoor environments.One of the key challenges in the outdoor displaying PCB industry is ensuring the durability and reliability of the PCBs in harsh outdoor conditions. Extreme temperatures, exposure to moisture, and potential physical damage from environmental factors are among the challenges that outdoor displaying PCBs must withstand. {} has addressed these challenges by employing advanced manufacturing processes and using high-quality materials to ensure that their PCBs meet the highest industry standards for reliability and longevity.In addition to the technical aspects, {} has also focused on providing excellent customer service and support. The company works closely with its customers to understand their specific requirements and to provide tailored solutions that meet their needs. With a commitment to quality and customer satisfaction, {} has built a strong reputation as a reliable partner for businesses seeking high-performance outdoor displaying PCBs.The future of the outdoor displaying PCB industry looks promising, with continued advancements in technology and an increasing demand for innovative outdoor display solutions. {} is poised to play a significant role in shaping the future of this industry, with its dedication to quality, innovation, and customer-centric approach.In conclusion, outdoor displaying PCBs have become an essential component of the outdoor advertising and signage industry, driving the demand for high-quality and reliable PCB solutions. {} has established itself as a leading provider of outdoor displaying PCBs, offering a wide range of products and excellent customer support. With its focus on innovation and quality, {} is well-positioned to meet the evolving needs of the market and contribute to the growth of the outdoor displaying PCB industry.

Innovative Rigid Flex Technology: Advantages and Applications

Rigid flex PCBs (printed circuit boards) have been gaining popularity in the electronics industry due to their ability to combine the benefits of both rigid and flexible PCBs. This innovative technology is being adopted by various industries, from consumer electronics to medical devices, and its demand is expected to grow in the coming years.Rigid flex PCBs are a type of circuit board that combines flexible PCBs with rigid PCBs, allowing for more complex and versatile designs. They are made from a combination of flexible substrate material and rigid laminate material, allowing them to bend and fold in ways that traditional rigid PCBs cannot. This flexibility opens up new possibilities for product design and allows for more compact and lightweight electronic devices.One company at the forefront of the rigid flex PCB industry is {}. With over 20 years of experience in the PCB manufacturing industry, {} has established itself as a leading provider of high-quality PCBs for a wide range of applications. The company's expertise in rigid flex PCBs has allowed them to stay ahead of the curve and meet the growing demand for this innovative technology.{}'s state-of-the-art manufacturing facilities and advanced technology allow them to produce rigid flex PCBs with high precision and reliability. Their team of experienced engineers and technicians works closely with clients to understand their specific requirements and provide customized solutions to meet their needs. Whether it's for aerospace, automotive, medical, or consumer electronics, {} has the capabilities to deliver top-notch rigid flex PCBs for any industry.One of the key advantages of rigid flex PCBs is their ability to reduce the overall size and weight of electronic devices. By eliminating the need for connectors and cables, rigid flex PCBs enable more compact and lightweight designs, making them ideal for portable and wearable electronics. This can lead to cost savings in production and improved performance in the final product.In addition to size and weight savings, rigid flex PCBs also offer improved reliability and durability. The elimination of connectors and cables reduces the risk of mechanical failure and signal interference, resulting in more reliable and robust electronic devices. This is particularly important in industries such as aerospace and medical, where failure is not an option.The versatility of rigid flex PCBs also allows for more complex and creative product designs. Their ability to bend and fold opens up new possibilities for innovative and ergonomic designs, giving engineers and designers more freedom to create unique and compelling products. This can lead to a competitive edge in the market and enhance the overall user experience.With the increasing demand for smaller, lighter, and more reliable electronic devices, the market for rigid flex PCBs is expected to continue growing in the coming years. Companies like {} are well-positioned to meet this demand with their advanced manufacturing capabilities and expertise in rigid flex PCB technology.As the electronics industry continues to evolve, rigid flex PCBs will play a crucial role in enabling new and exciting innovations. With their ability to combine the benefits of both rigid and flexible PCBs, they offer a compelling solution for a wide range of applications. As more companies and industries recognize the advantages of rigid flex PCBs, their adoption is expected to become more widespread, driving further growth and advancement in the electronics industry.

Top Tips for Choosing the Best Circuit Card Assembly in 2022

Circuit Card Assy, commonly known as CCA, is a critical component in a wide range of electronic devices. From consumer electronics to industrial machinery, CCAs are essential for ensuring the proper functioning of these devices. One company that has made a name for itself in the CCA manufacturing industry is a global leader in electronic manufacturing services. With a strong focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for businesses across various industries.The company's commitment to excellence is evident in its state-of-the-art manufacturing facilities and dedicated team of engineers and technicians. With a keen understanding of the latest technological advancements and market trends, the company continuously strives to develop cutting-edge CCAs that meet the evolving needs of its customers. This dedication to innovation has enabled the company to stay ahead of the competition and maintain its position as a leader in the electronic manufacturing industry.One of the key factors that set the company apart from its competitors is its unwavering commitment to quality. The company adheres to the highest industry standards and rigorous quality control processes to ensure that its CCAs meet the strictest performance and reliability requirements. This dedication to quality has earned the company numerous certifications and accolades, further solidifying its reputation as a trusted and reliable partner for electronic manufacturing services.In addition to quality, the company places a strong emphasis on customer satisfaction. By working closely with its clients and understanding their unique requirements, the company is able to deliver tailored solutions that address specific needs and challenges. Whether it's a custom-designed CCA for a niche market or a high-volume production run for a popular consumer electronics product, the company has the expertise and resources to deliver superior results.Furthermore, the company's commitment to sustainability and corporate responsibility sets it apart as a leader in the electronic manufacturing industry. By integrating eco-friendly practices into its operations and supply chain, the company strives to minimize its environmental impact and reduce its carbon footprint. This initiative not only benefits the planet but also aligns with the sustainability goals of its clients, making it an attractive partner for businesses looking to reduce their environmental impact.As the demand for electronic devices continues to grow, the company remains at the forefront of the industry, driving innovation and delivering high-quality CCAs to meet the needs of its diverse customer base. Whether it's a complex multi-layer CCA for a cutting-edge medical device or a simple circuit board for a consumer electronic product, the company has the expertise and capabilities to deliver top-notch solutions that exceed expectations.With a strong track record of success and a commitment to excellence, the company is poised to continue leading the electronic manufacturing industry for years to come. Its dedication to innovation, quality, customer satisfaction, and sustainability sets it apart as a trusted partner for businesses looking for superior electronic manufacturing services. As the industry evolves, the company remains steadfast in its mission to drive progress and deliver exceptional CCAs that power the electronic devices of today and tomorrow.

How to Debug a Single Test: Tips and Tricks

Jest Debug Single Test (need remove brand name)Developers and software testers know the struggle of debugging a single test. It can be a time-consuming and frustrating process, often requiring them to sift through lines of code to find the root cause of the issue. However, with the latest update from {}, debugging a single test has become easier and more efficient than ever before.The newest feature in {} allows developers to debug a single test using Jest, a popular JavaScript testing framework. This feature streamlines the debugging process and saves developers valuable time and effort. With just a few simple steps, developers can isolate and fix issues within a single test, ultimately leading to a more efficient and effective development process.{} is a leading provider of software development tools and services, with a strong focus on improving the efficiency and productivity of developers. Their latest update to {} demonstrates their commitment to providing cutting-edge solutions that address the pain points of software development.The company's dedication to innovation and continuous improvement is evident in their recent release of the debug single test feature. By addressing a common challenge faced by developers, {} is reaffirming their position as a trailblazer in the software development industry.The debug single test feature in {} offers a range of benefits to developers. Firstly, it simplifies the debugging process, allowing developers to quickly identify and resolve issues within a single test. This saves time and reduces the frustration often associated with debugging. Additionally, the feature provides a more focused approach to debugging, allowing developers to isolate specific issues without having to wade through an entire test suite.Furthermore, the debug single test feature enhances collaboration among development teams. By making it easier to pinpoint and fix issues within a single test, team members can work more cohesively and efficiently towards a common goal. This streamlined approach to debugging ultimately leads to a more productive and harmonious development process.For developers who are already familiar with Jest, the debug single test feature seamlessly integrates into their existing workflow. It is designed to be intuitive and easy to use, minimizing the learning curve and allowing developers to quickly reap the benefits of this new functionality. Additionally, {} provides comprehensive documentation and support to ensure that developers can make the most of the feature.The implementation of the debug single test feature underscores {}'s commitment to empowering developers with the tools they need to succeed. By continually seeking out ways to enhance the development process, {} is playing a pivotal role in driving innovation and progress within the software development industry.In conclusion, the latest update from {} introduces a game-changing feature for developers using Jest. The debug single test functionality offers a more efficient and focused approach to debugging, ultimately leading to a more productive development process. As {} continues to push the boundaries of software development, they are demonstrating their unwavering commitment to empowering developers and driving innovation within the industry. This latest release is undoubtedly a testament to {}'s vision and dedication to serving the needs of the developer community.

Ultimate Guide to Flex Circuit Assembly: Everything You Need to Know

Flex Circuit Assembly Offers Innovative Solutions for Electronic ManufacturingFlex Circuit Assembly is a leading provider of innovative solutions for electronic manufacturing. With a strong focus on quality, reliability, and flexibility, the company has earned a reputation as a trusted partner for businesses looking to streamline their production processes and bring their products to market quickly.Specializing in custom flex circuit assembly, the company leverages cutting-edge technology and state-of-the-art equipment to deliver high-quality electronic components that meet the unique needs of each client. From design and prototyping to full-scale production, Flex Circuit Assembly offers end-to-end solutions that enable businesses to stay ahead of the competition and meet the demands of today's fast-paced market.One of the key advantages of working with Flex Circuit Assembly is its ability to provide flexible and cost-effective manufacturing solutions. Whether clients require low-volume, high-mix production or high-volume, low-cost production, the company has the expertise and capabilities to meet their specific requirements. This flexibility allows businesses to scale their production as needed, without compromising on quality or performance.In addition to its custom flex circuit assembly services, Flex Circuit Assembly also offers a range of value-added services, including component sourcing, testing, and assembly. This comprehensive approach to electronic manufacturing enables clients to simplify their supply chain and reduce time-to-market, while ensuring that their products meet the highest quality standards.Flex Circuit Assembly takes pride in its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay at the forefront of technological advancements in the electronic manufacturing industry. By leveraging the latest materials, processes, and design techniques, Flex Circuit Assembly is able to deliver innovative solutions that help clients stay ahead in a rapidly evolving market.Furthermore, Flex Circuit Assembly places a strong emphasis on quality and reliability. The company follows rigorous quality control standards throughout the manufacturing process to ensure that every product meets the highest industry standards. Whether clients require rigid flex PCB assembly, flexible printed circuit boards, or any other type of electronic component, they can trust that Flex Circuit Assembly will deliver products that are built to last.With a customer-centric approach, Flex Circuit Assembly works closely with clients to understand their unique needs and challenges. The company's team of experienced engineers and technicians collaborates with clients from the initial design phase through to production, providing valuable insights and expertise to help optimize the manufacturing process and achieve the best results.In summary, Flex Circuit Assembly is a trusted partner for businesses looking to streamline their electronic manufacturing processes. With its commitment to quality, reliability, and innovation, the company offers a comprehensive range of solutions to help clients meet the demands of today's market. By leveraging cutting-edge technology, flexible manufacturing capabilities, and a customer-centric approach, Flex Circuit Assembly is well-positioned to continue leading the way in the electronic manufacturing industry.For more information about Flex Circuit Assembly and its innovative solutions for electronic manufacturing, visit their website at [insert company website].

Comparing Rigid and Flexible PCB: Understanding the Differences

Rigid and Flexible PCBs are some of the most essential components in modern electronic devices. Whether it's a smartphone, a computer, a car, or a medical device, PCBs play a crucial role in the functionality of these devices. {Company name} has been at the forefront of PCB manufacturing for over two decades. With a strong emphasis on quality, innovation, and customer satisfaction, {company name} has established itself as a trusted supplier of rigid and flexible PCBs to a wide range of industries including telecommunications, automotive, aerospace, and consumer electronics.Rigid PCBs are the traditional and most common type of PCB used in electronic devices. These boards are made of solid substrate materials such as fiberglass, and they are capable of supporting heavy components. Rigid PCBs are ideal for applications where durability and stability are paramount, such as in automotive electronics and industrial control systems.On the other hand, flexible PCBs are designed to be more versatile and adaptable to the shape and size requirements of the device they are used in. These boards are made of flexible substrate materials such as polyimide, which allows them to be bent, twisted, and folded without compromising their functionality. Flexible PCBs are widely used in portable electronic devices such as smartphones, tablets, and wearable technology.{Company name} has a comprehensive range of capabilities in the production of both rigid and flexible PCBs. Its state-of-the-art manufacturing facilities are equipped with advanced machinery and technology to ensure the highest quality and precision in every PCB produced. The company's team of experienced engineers and technicians are well-versed in the latest industry standards and best practices, allowing them to deliver PCB solutions that meet the most stringent requirements of their customers.In addition to its standard PCB offerings, {company name} also specializes in the design and production of custom PCBs tailored to the specific needs of its clients. Whether it's a complex multilayer rigid PCB for a telecommunications infrastructure project or a flexible PCB for a cutting-edge medical device, {company name} has the technical expertise and production capacity to deliver high-quality, custom PCB solutions.One of the key factors that sets {company name} apart from its competitors is its unwavering commitment to quality and reliability. The company adheres to strict quality control processes at every stage of the production cycle, from raw material inspection to final product testing. This rigorous approach to quality has earned {company name} the trust and confidence of its customers, who rely on the company for PCB solutions that perform consistently and reliably in their applications.Furthermore, {company name} is dedicated to environmental sustainability and ethical manufacturing practices. The company is certified to the highest industry standards for environmental management and occupational health and safety, demonstrating its commitment to minimizing its environmental footprint and ensuring the well-being of its employees.Looking ahead, {company name} continues to invest in research and development to stay at the forefront of PCB technology. The company is actively exploring new materials, processes, and design techniques to push the boundaries of what is possible in PCB manufacturing. By embracing innovation and continuous improvement, {company name} aims to remain a leader in the PCB industry and a go-to partner for companies seeking reliable and high-quality PCB solutions.In conclusion, {company name} is a reputable and reliable supplier of rigid and flexible PCBs for a wide range of industries. With its advanced manufacturing capabilities, commitment to quality, and dedication to innovation, {company name} is well-positioned to meet the evolving needs of the electronics industry and continue to serve as a trusted partner for its customers.

High-quality PCB Fabrication Services for Your Electronic Projects

On the cutting-edge of technology, PCB Fabrication is revolutionizing the world of electronic manufacturing. Specializing in the production of high-quality printed circuit boards (PCBs), the company has established itself as a leader in the industry. With state-of-the-art facilities and a team of experienced professionals, PCB Fabrication is dedicated to providing top-notch PCB solutions to its global clientele.With the increasing demand for advanced PCBs, PCB Fabrication has continuously invested in the latest manufacturing equipment and technologies to ensure that it stays ahead of the curve. The company's commitment to quality and innovation has allowed it to cater to a wide range of industries, including aerospace, telecommunications, automotive, and consumer electronics.At PCB Fabrication, the process of PCB manufacturing begins with the design and layout of the circuit boards. Utilizing advanced software and design tools, the company's engineering team works closely with customers to develop customized PCB solutions that meet their specific requirements. Once the design is finalized, PCB Fabrication's manufacturing facilities take over, employing state-of-the-art equipment to produce high-precision PCBs with quick turnaround times.One of the key differentiators of PCB Fabrication is its ability to produce both prototype and high-volume PCBs with consistent quality. With a focus on precision and reliability, the company's manufacturing processes undergo rigorous quality control measures to ensure that each PCB meets the highest industry standards. This attention to detail has earned PCB Fabrication a reputation for delivering superior PCB solutions that exceed customer expectations.In addition to its advanced manufacturing capabilities, PCB Fabrication also offers a range of value-added services to its customers. From component sourcing and assembly to testing and packaging, the company provides comprehensive PCB solutions that streamline the manufacturing process for its clients. This holistic approach allows PCB Fabrication to serve as a trusted partner for companies looking to bring their electronic products to market.Furthermore, PCB Fabrication is committed to environmental sustainability and responsible manufacturing practices. The company makes use of eco-friendly materials and adheres to strict environmental regulations in its manufacturing processes. By prioritizing sustainability, PCB Fabrication not only minimizes its environmental footprint but also ensures that its customers receive products that are in line with the highest ethical standards.PCB Fabrication's dedication to excellence and customer satisfaction has earned it a loyal customer base and a sterling reputation in the industry. Through its commitment to innovation, quality, and sustainability, the company has positioned itself as a leading provider of PCB solutions for diverse applications.As PCB Fabrication continues to expand its global reach, it remains steadfast in its mission to push the boundaries of electronic manufacturing. With a relentless pursuit of technological advancement and customer-centric approach, the company is poised to lead the industry into a new era of PCB innovation.In summary, PCB Fabrication's relentless commitment to excellence and innovation has established it as a powerhouse in the electronic manufacturing industry. With a focus on quality, precision, and sustainability, the company continues to raise the bar for PCB solutions, setting new standards for the industry as a whole. As it looks to the future, PCB Fabrication is poised to not only meet the evolving needs of its customers but to drive the next wave of electronic innovation.

Complete Guide to Pcb Board Assembly: Everything You Need to Know

Pcb Board Assembly, a leading provider of high-quality electronic manufacturing services, is proud to announce the launch of its state-of-the-art assembly facility in [location]. With over [number] years of experience in the industry, Pcb Board Assembly has established itself as a trusted partner for companies looking to outsource their electronic manufacturing needs.The new facility is equipped with the latest technology and machinery to ensure the highest level of precision and efficiency in the assembly process. From prototype to full production runs, Pcb Board Assembly has the capability to handle a wide range of project sizes and specifications. The facility also adheres to the highest quality standards and is certified to ISO [number] and [other relevant certifications]."We are excited to open our new assembly facility, which represents a significant investment in our capabilities and capacity," said [Name], CEO of Pcb Board Assembly. "This expansion allows us to better serve our customers and meet the growing demand for our services. We are committed to providing superior quality and service to our clients, and this new facility is a reflection of that commitment."In addition to its state-of-the-art facility, Pcb Board Assembly prides itself on its experienced team of engineers, technicians, and assembly specialists. The company's team is dedicated to providing personalized support and guidance to ensure that each project is completed to the highest standards. Whether it's a complex, high-density circuit board or a simple assembly job, Pcb Board Assembly has the expertise and resources to deliver results that exceed expectations.Furthermore, Pcb Board Assembly places a strong emphasis on sustainability and environmental responsibility. The company has implemented various measures to reduce its carbon footprint and minimize waste in its manufacturing processes. This commitment to sustainable practices aligns with the company's values and reflects its dedication to being a responsible corporate citizen.As a full-service electronic manufacturing partner, Pcb Board Assembly offers a comprehensive range of services, including PCB design and layout, component sourcing, PCB assembly, testing, and more. The company's capabilities cover a wide spectrum of industries, including aerospace, automotive, medical, telecommunications, and consumer electronics. With a focus on innovation and continuous improvement, Pcb Board Assembly is equipped to meet the evolving needs of the electronics manufacturing industry.Customer satisfaction is at the core of Pcb Board Assembly's business philosophy. The company strives to build long-lasting relationships with its clients based on trust, integrity, and reliability. By understanding each client's unique requirements and challenges, Pcb Board Assembly is able to tailor its services to deliver custom solutions that drive success and competitiveness in the market."We take pride in the relationships we have built with our customers over the years," said [Name]. "Their success is our success, and we are dedicated to supporting them every step of the way. Our new assembly facility is just one example of our ongoing commitment to providing the best possible service to our clients."In conclusion, Pcb Board Assembly's new assembly facility represents a significant milestone for the company and its commitment to excellence in electronic manufacturing. With its cutting-edge technology, experienced team, and unwavering dedication to customer satisfaction, Pcb Board Assembly is poised to continue its legacy as a leading provider of high-quality electronic manufacturing services.

Top 5 Tips for Ordering PCB Assembly

**PCB Assembly Order for {Company Name}{Date} – {Location}: {Company Name} is proud to announce the successful acquisition of a large PCB assembly order from a leading technology company. This achievement highlights {Company Name}'s expertise in providing high-quality electronic manufacturing services and further strengthens its position as a trusted partner for businesses in the technology industry.The recent PCB assembly order, which was secured after a rigorous selection process, underscores {Company Name}'s commitment to delivering innovative and reliable solutions to its clients. The company's state-of-the-art manufacturing facility and skilled workforce played a pivotal role in winning the order, showcasing its ability to meet the stringent demands of modern electronics manufacturing.Established in {Year}, {Company Name} has firmly established itself as a leading provider of electronic manufacturing services, offering a comprehensive range of solutions, including PCB assembly, cable harness assembly, and box build services. The company's dedication to quality, precision, and efficiency has earned it a stellar reputation in the industry, attracting clients from diverse sectors, including aerospace, automotive, healthcare, and consumer electronics.{Company Name}'s commitment to excellence is reflected in its adherence to industry standards and certifications. The company is ISO 9001 and AS9100 certified, ensuring that its manufacturing processes meet the highest quality and safety requirements. Additionally, {Company Name} is committed to sustainability and environmental responsibility, implementing green manufacturing practices and ensuring compliance with relevant regulations.The recent PCB assembly order serves as a testament to {Company Name}'s ability to meet the evolving needs of the technology industry. With an uncompromising focus on innovation and continuous improvement, the company is well-equipped to handle complex manufacturing projects and deliver superior results that exceed client expectations."We are extremely pleased to have secured this significant PCB assembly order," said {Spokesperson}, {Title} of {Company Name}. "It is a testament to our team's hard work, dedication, and expertise in electronic manufacturing. We are confident that our capabilities and commitment to excellence will enable us to meet and exceed the expectations of our valued clients."{Company Name}'s competitive advantage lies in its ability to provide end-to-end electronic manufacturing solutions, from prototype development to full-scale production. The company leverages advanced technologies and modern equipment to ensure accuracy, efficiency, and consistency in its manufacturing processes, enabling clients to bring their cutting-edge products to market with confidence.As the demand for sophisticated electronic devices continues to grow, {Company Name} remains at the forefront of the industry, leveraging its expertise and resources to support the rapidly evolving needs of its clients. With a customer-centric approach and a focus on building long-term partnerships, the company is poised to further expand its presence in the electronic manufacturing landscape.The successful acquisition of the PCB assembly order is a significant milestone for {Company Name}, signaling its readiness to take on ambitious projects and deliver impactful solutions that drive the success of its clients. With a track record of excellence, a dedication to innovation, and a commitment to quality, {Company Name} is well-positioned to lead the way in the electronic manufacturing industry and continue its trajectory of growth and success.For more information about {Company Name}'s electronic manufacturing services, visit {website}.Contact:{Company Name}{Address}{Phone}{Email}{Website}

Top High Power Inductor in 2023 - Ultimate Guide

High Power Inductor Innovations: A Game Changer in the Electronics IndustryIn today's fast-paced and technology-driven world, the demand for high-performance electronic components continues to rise. From consumer electronics to industrial applications, the need for reliable and efficient power management solutions has never been greater. This is where the High Power Inductor from {} comes into play - a revolutionary product that is set to change the game in the electronics industry.{} is a leading provider of innovative electronic components, specializing in power management solutions and magnetics. With a strong commitment to research and development, {} has continuously pushed the boundaries of technology to deliver cutting-edge products that meet the ever-evolving needs of the market.The High Power Inductor is the latest addition to the company's extensive portfolio of electronic components. Designed to address the growing demand for high-performance power management solutions, this innovative inductor offers a range of features and benefits that set it apart from traditional components in the market.One of the key highlights of the High Power Inductor is its exceptional power handling capabilities. With a high current rating and low electrical resistance, this inductor is capable of handling large amounts of power while maintaining optimum performance. This makes it an ideal choice for power supply applications, where efficiency and reliability are of utmost importance.Furthermore, the High Power Inductor is designed to operate at high frequencies, making it suitable for a wide range of applications in the electronics industry. Whether it's in switch-mode power supplies, automotive electronics, or industrial control systems, this inductor offers superior performance and stability across different operating conditions.Another notable feature of the High Power Inductor is its compact and robust design. Despite its high power handling capabilities, the inductor is engineered to be space-efficient, allowing for greater flexibility in design and integration. This is particularly beneficial for manufacturers looking to optimize the size and weight of their products without compromising on performance.Additionally, the High Power Inductor is built to withstand the most demanding environmental conditions, making it suitable for use in harsh operating environments. Its rugged construction and high-temperature tolerance ensure long-term reliability, making it an ideal choice for mission-critical applications in aerospace, defense, and industrial sectors.With the increasing focus on energy efficiency and sustainability, the High Power Inductor also offers significant advantages in terms of minimizing power losses and optimizing overall system performance. By leveraging advanced materials and manufacturing techniques, {} has been able to develop an inductor that delivers superior efficiency and helps reduce energy consumption in electronic systems.In line with {}'s commitment to quality and innovation, the High Power Inductor has undergone rigorous testing and validation to ensure compliance with industry standards and regulations. This includes comprehensive thermal, electrical, and mechanical testing, as well as environmental testing to validate its performance in real-world applications.In conclusion, the High Power Inductor from {} represents a significant milestone in the field of power management and magnetics. With its unparalleled power handling capabilities, high-frequency operation, compact design, and robust construction, this innovative inductor is set to revolutionize the way electronic systems are powered and managed.As the demand for high-performance electronic components continues to grow, the High Power Inductor is poised to play a crucial role in shaping the future of the electronics industry. With its ability to deliver exceptional performance, efficiency, and reliability, this inductor is a testament to {}'s relentless pursuit of excellence and its dedication to pushing the boundaries of technology.