Innovative Active Diode Circuit Technology: What You Need to Know

By:Admin

{} is a global leader in semiconductor manufacturing and technology, specializing in the development of cutting-edge electronic components for a wide range of applications. With a strong focus on research and development, the company has been at the forefront of advancing semiconductor technology, and its latest breakthrough in ADC technology is set to revolutionize the industry.

The Active Diode Circuit (ADC) is a novel electronic circuit that offers significant advantages over traditional diode circuits. By using active components such as transistors to control the behavior of diodes, ADC technology enables improved performance, efficiency, and reliability in electronic devices. This breakthrough has the potential to enhance the functionality of a wide range of electronic products, from smartphones and laptops to automotive systems and industrial equipment.

{}’s proprietary ADC technology has been developed over several years of intensive research and testing, and the company holds multiple patents for its innovative circuit design. By leveraging its expertise in semiconductor manufacturing and design, {} has been able to produce ADC components that offer unmatched performance and reliability.

One of the key benefits of {}’s ADC technology is its ability to improve energy efficiency in electronic devices. By actively controlling the behavior of diodes, ADCs can minimize power losses and improve the overall energy efficiency of electronic circuits. This is particularly important in today's electronic devices, where energy consumption is a growing concern for both consumers and manufacturers.

In addition to energy efficiency, {}’s ADC technology also offers enhanced performance and reliability. By actively managing the behavior of diodes, ADCs can reduce signal distortion, improve signal integrity, and minimize the risk of component failure. This is particularly important in high-performance electronic products, where reliability and consistency are critical.

{}’s ADC technology has already gained significant traction in the market, with several major electronics manufacturers incorporating ADC components into their latest products. From smartphones and tablets to automotive infotainment systems and industrial control equipment, ADC technology is poised to become a standard feature in a wide range of electronic devices.

Looking ahead, {} is committed to further advancing ADC technology and exploring new applications for this innovative circuit design. With a dedicated team of engineers and researchers, the company is continuously pushing the boundaries of what is possible in semiconductor technology. By staying at the forefront of innovation, {} aims to cement its position as a global leader in semiconductor technology and continue to drive progress in the electronics industry.

In conclusion, Active Diode Circuit (ADC) technology is poised to revolutionize the electronics industry, and {} is at the forefront of this innovation. With its proprietary ADC technology, the company is setting new standards for energy efficiency, performance, and reliability in electronic devices. As ADC technology continues to gain momentum in the market, {} is well-positioned to lead the way in shaping the future of semiconductor technology.

Company News & Blog

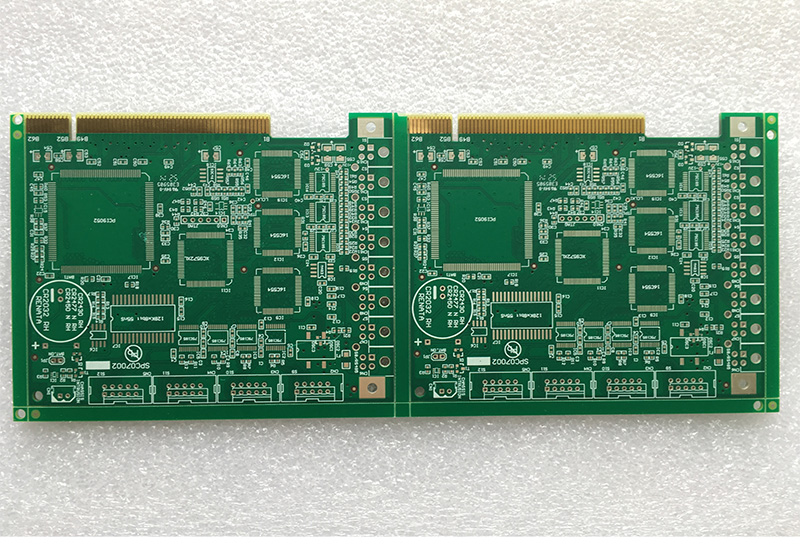

Optimize Your Production Line with Automated PCB Testing

Automated PCB Testing Revolutionizes Quality Control at {}In the era of advanced technology and fast-paced production processes, the need for efficient quality control has become more crucial than ever. With the increasing complexity of electronic components, the demand for reliable and accurate testing methods has surged. One company that has truly embraced this challenge is {}.Based in the heart of the electronic manufacturing hub, {} has been a key player in providing cutting-edge solutions for the printed circuit board (PCB) industry. With a strong commitment to innovation and precision, the company has recently introduced an automated PCB testing system that is set to revolutionize the quality control process.The automated PCB testing system developed by {} represents a significant advancement in the industry. By combining state-of-the-art technology with a deep understanding of the challenges faced by electronic manufacturers, {} has created a solution that promises to streamline the testing process and deliver superior results.Traditionally, PCB testing has been a time-consuming and labor-intensive task, often prone to errors and inconsistencies. Manual testing methods are not only slow and inefficient, but also leave room for human error, leading to potential defects slipping through the cracks. {}'s automated testing system addresses these issues by offering a seamless and reliable testing process that ensures the highest level of quality control.One of the key features of {}'s automated PCB testing system is its ability to detect defects with unmatched precision. Equipped with advanced sensors and intelligent algorithms, the system is capable of identifying even the smallest imperfections in PCBs, ensuring that only the highest quality products make it to the market. This level of accuracy not only enhances the overall quality control process but also helps to minimize the risk of product recalls and costly rework.Moreover, the automated testing system significantly reduces the time and resources required for testing. By automating the process, {} has managed to greatly increase efficiency and throughput, enabling manufacturers to meet tight production deadlines without compromising on quality. This is particularly crucial in today's fast-paced manufacturing environment, where time-to-market is a critical factor in staying competitive.In addition to its technical capabilities, {}'s automated PCB testing system is designed with user-friendliness in mind. The intuitive interface and easy-to-use controls make it accessible to operators of all levels of expertise, eliminating the need for extensive training and reducing the likelihood of operator error. This ensures that the system can be seamlessly integrated into existing production lines without causing disruptions or delays.Furthermore, {} provides comprehensive technical support and training to its clients, ensuring that they can maximize the benefits of the automated testing system. With a team of experienced engineers and technical experts, the company is committed to assisting its customers in optimizing their testing processes and achieving the best possible outcomes.The introduction of {}'s automated PCB testing system marks a significant milestone in the evolution of quality control in the electronic manufacturing industry. By leveraging the power of automation and advanced technology, {} has set a new standard for PCB testing, offering a solution that is not only more accurate and efficient but also more accessible and user-friendly.As the demand for high-quality electronic components continues to grow, the importance of reliable and efficient testing methods cannot be overstated. With its automated PCB testing system, {} has positioned itself as a leader in providing innovative solutions that address the key challenges faced by manufacturers, ultimately contributing to the advancement of the electronics industry as a whole.

Ultimate Guide to Printed Circuit Card Design and Manufacturing

Printed Circuit Card (PCC) has been making waves in the electronics industry with its cutting-edge technology and innovative approach to manufacturing. The company, founded in 1995, has quickly established itself as a leader in the production of high-quality printed circuit boards for a wide range of applications.PCC's success can be attributed to its state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians. The company's commitment to quality and customer satisfaction has earned it a reputation for reliability and excellence in the industry.PCC specializes in the production of rigid, flex, and rigid-flex circuit boards, serving customers in industries such as aerospace, medical, telecommunications, and consumer electronics. The company's capabilities include high-density interconnect (HDI) boards, multi-layer boards, and quick-turn prototypes, allowing it to meet the diverse needs of its customers.In addition to its advanced manufacturing capabilities, PCC is also known for its dedication to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve and offer its customers the latest advancements in circuit board technology.One of PCC's key strengths is its ability to provide customized solutions to meet the unique requirements of each customer. Whether it's a complex multi-layer board for a medical device or a high-frequency rigid-flex board for a telecommunications application, PCC has the expertise and resources to deliver a high-quality product that meets or exceeds expectations.Furthermore, PCC is committed to sustainability and environmental responsibility in its manufacturing processes. The company adheres to strict environmental standards and continuously seeks ways to minimize its impact on the planet while delivering top-notch products to its global customer base.With its strong focus on quality, innovation, and customer satisfaction, PCC has gained the trust and loyalty of a diverse customer base. From start-ups to established multinational corporations, PCC has been the go-to partner for companies seeking reliable and high-performance printed circuit boards.Looking ahead, PCC is poised to continue its growth and expansion in the electronics industry. With a constant eye on emerging technologies and shifting customer demands, the company is well-positioned to remain a leader in the competitive market for printed circuit boards.In conclusion, PCC's dedication to excellence, innovation, and customer satisfaction has cemented its position as a leading provider of printed circuit boards. With its advanced manufacturing capabilities, commitment to sustainability, and a focus on customization, PCC is well-equipped to meet the evolving needs of the electronics industry and serve as a trusted partner for businesses worldwide.

Affordable Small Batch PCB Assembly Services for Your Electronic Projects

In today's fast-paced technology-driven world, the demand for small batch PCB assembly services is on the rise. With the increasing complexity and miniaturization of electronic devices, there is a growing need for manufacturers to produce high-quality, low-volume PCBs for prototyping and small-scale production. This is where {Company Name} comes in.{Company Name} is a leading provider of {Company's specialty} solutions for a wide range of industries, including telecommunications, automotive, medical, and consumer electronics. With state-of-the-art facilities and a team of experienced engineers, {Company Name} is well-equipped to handle small batch PCB assembly projects with precision and efficiency.One of the key advantages of choosing {Company Name} for small batch PCB assembly is their commitment to quality. They adhere to strict quality control standards throughout the entire assembly process, ensuring that each PCB meets the highest industry standards. This attention to detail is crucial for companies looking to test new products and technologies before full-scale production.In addition to quality, {Company Name} offers fast turnaround times for small batch PCB assembly. They understand the time-sensitive nature of product development and are dedicated to meeting tight deadlines without compromising on quality. Whether it's a small run of prototype PCBs or a limited production run for a niche market, {Company Name} has the capability to deliver within short timeframes.Another key strength of {Company Name} is their ability to provide customized solutions for small batch PCB assembly. They work closely with clients to understand their specific requirements and tailor their assembly processes accordingly. This flexibility allows companies to test new designs and concepts without being constrained by high-volume production requirements.Furthermore, {Company Name} employs the latest technological advancements in PCB assembly, including advanced surface mount and through-hole assembly techniques. This enables them to handle complex PCB designs with tight component placement and high-density interconnects. Their expertise in these areas makes them a preferred choice for companies with small batch PCB assembly needs.{Company Name} also prides itself on its commitment to sustainability and environmental responsibility. They adhere to strict environmental standards and regulations in their assembly processes, ensuring that their operations have minimal impact on the environment. For companies looking to align with eco-friendly partners, {Company Name} offers a responsible and ethical choice for small batch PCB assembly services.In summary, {Company Name} is a trusted partner for companies in need of small batch PCB assembly services. With a focus on quality, speed, customization, and sustainability, they have established themselves as a leading provider in the industry. Their expertise and commitment to excellence make them a valuable asset for businesses looking to bring innovative electronic products to market.For more information about {Company Name} and their small batch PCB assembly services, visit their website or contact their team directly to discuss specific project requirements.

Step-by-step guide to surface mount assembly process

[Company Name] is a leading provider of innovative electronic solutions, serving a diverse range of industries such as automotive, consumer electronics, telecommunications, and medical devices. With a strong focus on cutting-edge technology and exceptional quality, [Company Name] has established itself as a key player in the field of electronic manufacturing services.Recently, [Company Name] unveiled its advanced Surface Mount Assembly Process, showcasing its commitment to staying at the forefront of technological advancements in the industry. The Surface Mount Assembly Process is a critical step in the production of electronic components and plays a pivotal role in the overall performance and reliability of the final product.The Surface Mount Assembly Process at [Company Name] utilizes state-of-the-art equipment and precision engineering to ensure that electronic components are seamlessly integrated onto the surface of the printed circuit board (PCB). This process is essential for creating compact and high-density electronic assemblies, which are increasingly in demand in today's fast-paced technological landscape.One of the key advantages of [Company Name]'s Surface Mount Assembly Process is its ability to accommodate a wide range of component sizes and package types, making it suitable for a diverse array of electronic products. Whether it's small and delicate components for handheld devices or larger components for industrial applications, [Company Name] has the capability to handle it all with utmost precision and efficiency.Furthermore, the Surface Mount Assembly Process at [Company Name] is designed to meet the strictest quality standards. The company adheres to rigorous quality control measures at every stage of the assembly process, ensuring that the finished products meet or exceed customer expectations. This commitment to quality is further reinforced by [Company Name]'s adherence to industry certifications and standards, demonstrating its dedication to delivering reliable and high-performance electronic solutions.In addition to its cutting-edge technology and stringent quality control, [Company Name] takes pride in its team of highly skilled and experienced professionals. The company's engineers and technicians are equipped with the expertise and knowledge to handle complex surface mount assembly challenges, providing customers with the confidence that their electronic products are in capable hands.With the unveiling of its advanced Surface Mount Assembly Process, [Company Name] aims to further cement its position as a leader in electronic manufacturing services. By offering a comprehensive and reliable solution for surface mount assembly, the company seeks to address the evolving needs of its customers and contribute to the advancement of technological innovation across various industries.In conclusion, [Company Name] continues to set new benchmarks in electronic manufacturing services with the introduction of its advanced Surface Mount Assembly Process. With a focus on cutting-edge technology, uncompromising quality, and a team of skilled professionals, the company is well-positioned to meet the increasingly complex demands of the electronic industry. As [Company Name] looks ahead, it remains committed to driving innovation and delivering exceptional electronic solutions that exceed customer expectations.

Why Military Forces Employ PCB Technology for Advanced Operations

This just in: The army has been making use of printed circuit boards (PCBs) in their latest equipment to enhance communication and technology capabilities on the battlefield. This cutting-edge technology provides soldiers with advanced communication and information systems, allowing for a more efficient and effective military presence in combat situations.The use of PCBs in military equipment is not a new concept. In fact, PCBs have been a critical component in military equipment for decades, providing a reliable and durable platform for electronic components to operate in harsh and demanding environments. These boards are essential in ensuring that electronic systems within military equipment can withstand the rigors of combat and operate with precision and accuracy.One company at the forefront of providing PCBs for military applications is {}. With years of experience in designing and manufacturing high-quality PCBs, {} has proven to be a trusted partner for various military organizations around the world. Their commitment to innovation and excellence has made them a go-to supplier for PCBs in the military sector.{} specializes in providing rugged and reliable PCBs that are specifically designed to meet the demands of military applications. These boards are built to withstand extreme temperatures, shock, and vibration, making them an ideal choice for military equipment operating in challenging environments. Whether it's for communication systems, surveillance equipment, or control panels, {} has the expertise to deliver PCB solutions that meet the stringent requirements of the military.The utilization of {}'s PCBs in military equipment has not only enhanced the performance of these systems but has also contributed to the overall effectiveness of military operations. By providing reliable and robust PCBs, {} plays a crucial role in ensuring that soldiers have access to the latest technology and communication systems, giving them a significant advantage on the battlefield.In addition to their expertise in designing and manufacturing PCBs for military applications, {} is also dedicated to upholding the highest standards of quality and conformity to strict military regulations and standards. The company's commitment to excellence and adherence to military specifications are paramount in ensuring that their products meet the rigorous demands of military operations.With the increasing reliance on advanced technology in modern warfare, the use of PCBs in military equipment is expected to continue growing. As military organizations seek to enhance their communication and technology capabilities, companies like {} will play a pivotal role in providing cutting-edge PCB solutions that meet the unique requirements of military applications.In conclusion, the utilization of PCBs in military equipment is a critical component in enhancing the communication and technology capabilities of military operations. With companies like {} at the forefront of providing high-quality and reliable PCB solutions, the military can be assured that their equipment will perform with precision and durability in the most demanding environments. As technology continues to evolve, the role of PCBs in military equipment will undoubtedly remain crucial in ensuring the effectiveness and success of military operations.

Comparing Rigid and Flexible PCB: Understanding the Differences

Rigid and Flexible PCBs are some of the most essential components in modern electronic devices. Whether it's a smartphone, a computer, a car, or a medical device, PCBs play a crucial role in the functionality of these devices. {Company name} has been at the forefront of PCB manufacturing for over two decades. With a strong emphasis on quality, innovation, and customer satisfaction, {company name} has established itself as a trusted supplier of rigid and flexible PCBs to a wide range of industries including telecommunications, automotive, aerospace, and consumer electronics.Rigid PCBs are the traditional and most common type of PCB used in electronic devices. These boards are made of solid substrate materials such as fiberglass, and they are capable of supporting heavy components. Rigid PCBs are ideal for applications where durability and stability are paramount, such as in automotive electronics and industrial control systems.On the other hand, flexible PCBs are designed to be more versatile and adaptable to the shape and size requirements of the device they are used in. These boards are made of flexible substrate materials such as polyimide, which allows them to be bent, twisted, and folded without compromising their functionality. Flexible PCBs are widely used in portable electronic devices such as smartphones, tablets, and wearable technology.{Company name} has a comprehensive range of capabilities in the production of both rigid and flexible PCBs. Its state-of-the-art manufacturing facilities are equipped with advanced machinery and technology to ensure the highest quality and precision in every PCB produced. The company's team of experienced engineers and technicians are well-versed in the latest industry standards and best practices, allowing them to deliver PCB solutions that meet the most stringent requirements of their customers.In addition to its standard PCB offerings, {company name} also specializes in the design and production of custom PCBs tailored to the specific needs of its clients. Whether it's a complex multilayer rigid PCB for a telecommunications infrastructure project or a flexible PCB for a cutting-edge medical device, {company name} has the technical expertise and production capacity to deliver high-quality, custom PCB solutions.One of the key factors that sets {company name} apart from its competitors is its unwavering commitment to quality and reliability. The company adheres to strict quality control processes at every stage of the production cycle, from raw material inspection to final product testing. This rigorous approach to quality has earned {company name} the trust and confidence of its customers, who rely on the company for PCB solutions that perform consistently and reliably in their applications.Furthermore, {company name} is dedicated to environmental sustainability and ethical manufacturing practices. The company is certified to the highest industry standards for environmental management and occupational health and safety, demonstrating its commitment to minimizing its environmental footprint and ensuring the well-being of its employees.Looking ahead, {company name} continues to invest in research and development to stay at the forefront of PCB technology. The company is actively exploring new materials, processes, and design techniques to push the boundaries of what is possible in PCB manufacturing. By embracing innovation and continuous improvement, {company name} aims to remain a leader in the PCB industry and a go-to partner for companies seeking reliable and high-quality PCB solutions.In conclusion, {company name} is a reputable and reliable supplier of rigid and flexible PCBs for a wide range of industries. With its advanced manufacturing capabilities, commitment to quality, and dedication to innovation, {company name} is well-positioned to meet the evolving needs of the electronics industry and continue to serve as a trusted partner for its customers.

High Definition Interconnect PCB Fabrication: Everything You Need to Know

HDI PCB Fabrication: A Closer Look at Advanced TechnologyIn today's fast-paced and technology-driven world, the demand for high-density interconnect (HDI) printed circuit boards (PCBs) continues to grow. As a key player in the electronic manufacturing industry, the need for advanced and reliable HDI PCB fabrication solutions has become increasingly important. This is where Company X comes into the picture. Their expertise in providing high-quality, cost-effective, and efficient HDI PCB fabrication services has made them a leader in the field.Company X is a top-notch manufacturer specializing in HDI PCB fabrication, with a proven track record of delivering exceptional products to a wide range of industries, including telecommunications, automotive, medical devices, and consumer electronics. Their state-of-the-art facility is equipped with the latest technology and manufacturing processes to ensure the highest quality and precision in every PCB they produce.With a team of experienced engineers and technicians, Company X is committed to staying at the forefront of innovation in HDI PCB fabrication. Their dedication to research and development has led to the creation of cutting-edge solutions that meet the evolving needs of their clients. By leveraging advanced materials and manufacturing techniques, they are able to produce HDI PCBs with increased functionality, smaller form factors, and improved performance, all while maintaining strict compliance with industry standards and regulations.One of the key factors that sets Company X apart from the competition is their ability to offer a comprehensive range of HDI PCB fabrication services, including PCB design, assembly, and testing. This full suite of offerings allows their clients to streamline their production processes and ensures that their PCBs are manufactured with the utmost care and attention to detail.Furthermore, Company X places a strong emphasis on quality control throughout the entire fabrication process. Their rigorous inspection and testing procedures guarantee that every HDI PCB meets the highest standards for reliability, durability, and performance. This commitment to quality has earned them the trust and loyalty of their customers, who rely on Company X to deliver superior products that consistently exceed their expectations.In addition to their technical expertise, Company X takes great pride in their customer-centric approach. They understand that every client has unique requirements and work closely with them to develop customized solutions that address their specific needs. Whether it's a prototype for a new product or a large-scale production run, Company X is dedicated to delivering results that align with their clients' goals and objectives.Looking ahead, Company X remains focused on staying ahead of the curve in HDI PCB fabrication. They continue to invest in research and development to explore new materials, processes, and technologies that will further enhance the performance and capabilities of their PCBs. By taking a proactive approach to innovation, they strive to be at the forefront of industry trends and deliver value-added solutions that give their clients a competitive edge in their respective markets.As the demand for smaller, faster, and more complex electronic devices continues to grow, the need for reliable and efficient HDI PCB fabrication will only become more critical. Company X is well positioned to meet these evolving demands with their unwavering commitment to excellence and their ability to push the boundaries of what is possible in HDI PCB fabrication. With a solid reputation for delivering top-tier products and a dedication to continuous improvement, Company X is poised to remain a trusted partner for companies seeking high-quality HDI PCB fabrication solutions.

How to Optimize Your PCB Design for Better Performance

Proteus PCB Design, a well-established leader in the field of electronic design automation software, has recently released their latest version of PCB design software, providing engineers and designers with even more powerful tools and features to streamline the design process and bring their ideas to life.Proteus PCB Design software has been at the forefront of PCB design for over [X] years. The company has built a reputation for delivering high-quality and innovative software solutions that cater to the needs of electronic design professionals across the globe. With a strong focus on user-friendly interfaces and advanced functionality, Proteus PCB Design has become a trusted partner for engineers and designers looking to create efficient and reliable PCB layouts.The latest release of Proteus PCB Design software introduces a range of new features and enhancements that aim to improve the overall design experience for users. One of the key highlights of the new release is the enhanced design rule checking (DRC) functionality, which allows users to perform thorough design rule checks to ensure that their PCB layouts adhere to industry standards and best practices. This feature helps to identify potential design flaws and errors early in the design process, saving both time and resources in the long run.In addition, the new release also includes advanced routing capabilities, allowing users to create and optimize complex PCB traces with ease. The software's improved autorouting algorithms help designers to achieve optimal signal integrity and reduce signal interference, resulting in higher-quality PCB designs.Furthermore, the latest release of Proteus PCB Design software incorporates a range of new component libraries, providing users with access to an extensive collection of pre-designed components, footprints, and symbols. This feature significantly reduces the time required to create new PCB designs, as users can simply drag and drop pre-designed components into their layouts, saving valuable time and effort."We are excited to announce the release of our latest version of Proteus PCB Design software," said [spokesperson], [title] at Proteus PCB Design. "With the introduction of these new features and enhancements, we aim to provide our users with a more efficient and intuitive design experience, ultimately enabling them to bring their innovative ideas to market faster and more effectively."Proteus PCB Design's commitment to delivering high-quality software solutions is further exemplified by their dedication to customer support and satisfaction. The company offers a range of comprehensive training and support services to help users maximize the potential of their software, ensuring that they are equipped with the knowledge and resources to tackle their design challenges confidently.As a testament to their industry-leading software, Proteus PCB Design has garnered a loyal customer base, with companies across various industries leveraging their software to drive innovation and achieve success in their electronic design projects."The new release of Proteus PCB Design software underscores our ongoing commitment to empowering engineers and designers with the tools they need to excel in their work," added [spokesperson]. "We are proud to continue our legacy of delivering cutting-edge PCB design solutions that are both powerful and user-friendly, and we look forward to seeing the incredible designs that our users will create with our latest software."With the release of their latest version of PCB design software, Proteus PCB Design reaffirms its position as a leading provider of electronic design automation solutions, delivering innovative software that enables engineers and designers to bring their ideas to life with efficiency and precision.

High-quality Circuit Board Assembly Services for Electronic Products

Circuit Board Assembly, a vital process in the production of electronic devices, is an intricate and complex procedure that requires precision and expertise. One company that excels in circuit board assembly is [Company Name]. With their state-of-the-art facilities and skilled professionals, [Company Name] has positioned itself as a leader in the industry, delivering high-quality circuit board assembly solutions to various clients.[Company Name] specializes in providing comprehensive circuit board assembly services, catering to the needs of clients across different sectors including consumer electronics, automotive, aerospace, medical devices, and more. The company’s commitment to delivering top-notch services has earned them a stellar reputation in the industry.With a focus on innovation and advanced technology, [Company Name] utilizes cutting-edge equipment and processes to ensure that their circuit board assembly solutions meet the highest standards. Their team of highly trained engineers and technicians are adept at handling complex assembly tasks, ensuring that each circuit board is assembled with precision and accuracy.One of the key factors that set [Company Name] apart from its competitors is its dedication to quality control. The company follows rigorous quality assurance protocols to guarantee that every circuit board assembly meets the strictest industry standards. This commitment to quality has resulted in satisfied clients who rely on [Company Name] for their circuit board assembly needs.Furthermore, [Company Name] prides itself on its ability to offer customized solutions to meet the specific requirements of each client. Whether it’s a small-scale project or a large-scale production run, the company has the capacity and expertise to handle diverse assembly needs, ensuring that clients receive tailor-made solutions that align with their objectives and specifications.In addition to their technical capabilities, [Company Name] is also known for its commitment to sustainability and environmental responsibility. The company adheres to eco-friendly practices in its assembly processes, minimizing its environmental footprint and contributing to a cleaner and greener planet.As the demand for electronic devices continues to rise, the need for reliable circuit board assembly services becomes increasingly important. [Company Name] recognizes this demand and remains dedicated to providing efficient and cost-effective assembly solutions to meet the evolving needs of the electronics industry.In conclusion, [Company Name] stands out as a prominent player in the circuit board assembly sector, offering a comprehensive range of services that are backed by industry-leading expertise, cutting-edge technology, and a steadfast commitment to quality. With a focus on customization, sustainability, and innovation, the company is well-positioned to meet the diverse and dynamic needs of clients across various industries, solidifying its position as a trusted partner for circuit board assembly solutions.

Cutting-Edge Technology: The Advantages of Flexible Printed Boards

Flexible Printed Board Market Expected to Grow as Demand for Flexible and Lightweight Electronics RisesThe global flexible printed board market is expected to witness significant growth in the coming years due to the increasing demand for flexible and lightweight electronic devices. Flexible printed boards, also known as FPCBs, are highly flexible and can be bent and twisted to fit into small and irregularly shaped spaces, making them ideal for use in a wide range of electronic applications.The market for flexible printed boards is being driven by the growing adoption of flexible electronics in various industries such as consumer electronics, automotive, healthcare, and aerospace. These industries are increasingly using flexible printed boards in applications such as wearables, smartphones, tablets, automotive infotainment systems, medical devices, and aircraft interiors.One company that is at the forefront of this growing market is {}. {} is a leading manufacturer of high-quality flexible printed boards that are used in a wide range of electronic applications. The company's extensive product portfolio includes single-sided, double-sided, and multi-layer flexible printed boards, as well as rigid-flex boards, which combine the benefits of both flexible and rigid printed boards.{}'s flexible printed boards are known for their high reliability, excellent thermal stability, and superior electrical performance. The company's state-of-the-art manufacturing facilities and advanced production processes ensure that its products meet the highest quality standards, making them the preferred choice for many leading companies in the electronics industry.With a strong focus on innovation and technology, {} is constantly pushing the boundaries of what is possible with flexible printed boards. The company's dedicated research and development team is continuously working on developing new materials and processes to further improve the performance and flexibility of its products. This relentless commitment to innovation has enabled {} to stay ahead of the competition and maintain its position as a market leader in the flexible printed board industry.As the demand for flexible and lightweight electronic devices continues to grow, {} is well-positioned to capitalize on this trend and further expand its market presence. The company's strong customer relationships, global distribution network, and commitment to delivering the highest quality products have earned it a reputation as a trusted and reliable partner for companies looking for flexible printed board solutions.In addition to its focus on product quality and innovation, {} is also committed to sustainability and environmental responsibility. The company has implemented stringent environmental management practices and has made significant investments in eco-friendly manufacturing processes to minimize its impact on the environment.Looking ahead, the future looks bright for the flexible printed board market, and {} is poised to play a key role in driving its growth. With its strong focus on innovation, technology, and sustainability, the company is well-equipped to meet the evolving needs of the electronics industry and continue providing cutting-edge flexible printed board solutions to its customers around the world.