Understanding the Importance of Audio Inductors in Electronics

By:Admin

The new line of inductors from Audio Inductors is set to revolutionize the audio industry, offering advanced features and capabilities that will enhance the performance of audio systems. These inductors are designed to deliver superior sound quality, with exceptional clarity and precision. Whether it's for professional audio equipment or high-end consumer audio systems, these inductors are engineered to meet the demands of even the most discerning audiophiles.

One of the key features of the new line of inductors is their advanced design, which incorporates cutting-edge technology to ensure optimal performance. By leveraging the latest materials and manufacturing techniques, Audio Inductors has been able to create inductors that offer superior electrical properties and efficiency. This translates to better overall performance and reliability, making these inductors an ideal choice for high-performance audio systems.

In addition to their technical prowess, the new inductors also boast a sleek and modern design that is sure to appeal to audio enthusiasts. With a compact and streamlined form factor, these inductors are easy to integrate into a wide range of audio systems, offering flexibility and versatility. This allows for seamless integration into various audio equipment, without compromising on performance or aesthetics.

Furthermore, Audio Inductors is also proud to announce that their new line of inductors is backed by rigorous testing and quality assurance processes. Every unit undergoes extensive testing to ensure that they meet the highest standards of performance and reliability. This dedication to quality is a testament to Audio Inductors' commitment to providing their customers with products that they can trust.

With the launch of their new line of inductors, Audio Inductors continues to solidify their position as a leader in the audio industry. Their dedication to innovation and excellence has earned them a reputation as a trusted partner for audio professionals and enthusiasts alike. By delivering products that embody the latest advancements in audio technology, Audio Inductors is poised to shape the future of audio systems and set new benchmarks for performance and quality.

As a company, Audio Inductors is known for their unwavering commitment to customer satisfaction. Their team of experts is always on hand to provide support and guidance, ensuring that their customers have access to the best possible solutions for their audio needs. With a focus on collaboration and partnership, Audio Inductors goes above and beyond to deliver exceptional value to their customers, setting them apart as a true industry leader.

In conclusion, the launch of the new line of inductors from Audio Inductors represents a significant milestone in the audio industry. With their advanced design, superior performance, and unwavering commitment to quality, these inductors are poised to raise the bar for audio systems and delight enthusiasts around the world. As Audio Inductors continues to push the boundaries of audio technology, they are sure to remain at the forefront of the industry for years to come.

Company News & Blog

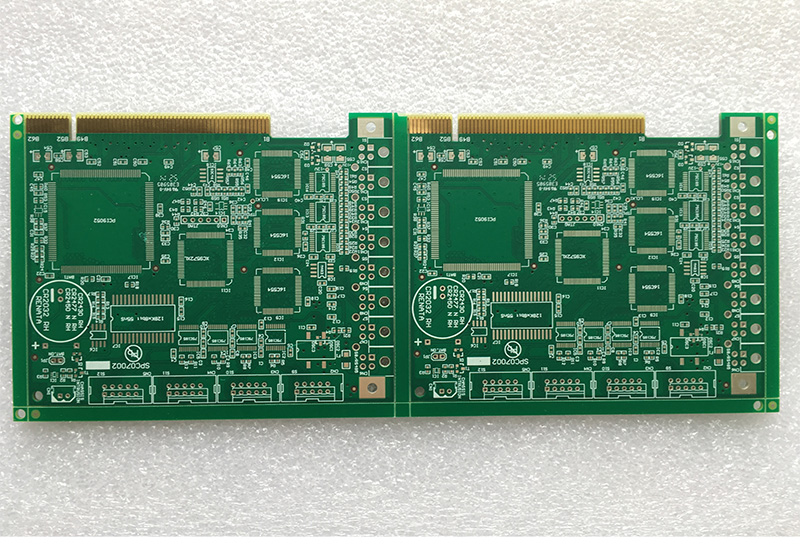

Tips for Optimal PCB Assembly and Manufacturing Process

PCBAssemblyExpress, one of the leading providers of printed circuit board (PCB) assembly services, has recently announced the launch of their new state-of-the-art manufacturing facility. This new facility is equipped with advanced technology and cutting-edge machinery to meet the increasing demand for high-quality PCB assembly services in the electronics industry.With over 10 years of experience in the PCB assembly industry, PCBAssemblyExpress has built a reputation for delivering top-notch services to a wide range of clients, including businesses in the automotive, aerospace, medical, and telecommunications sectors. The company’s commitment to quality, precision, and on-time delivery has made them a trusted partner for many companies looking for reliable PCB assembly solutions.The new manufacturing facility is strategically located to provide easy access to transportation and logistics networks, ensuring efficient delivery of finished products to customers worldwide. The facility boasts a robust infrastructure, including clean rooms and ESD-safe work areas, to ensure the highest quality standards in PCB assembly and manufacturing.In addition to the cutting-edge infrastructure, PCBAssemblyExpress has invested in the latest automated assembly equipment to streamline the production process and improve overall efficiency. The company’s team of highly skilled engineers and technicians are trained to operate these advanced machines and leverage their capabilities to deliver exceptional results for every project.“We are thrilled to announce the launch of our new manufacturing facility, which represents a significant milestone for our company,” said [Insert Name], CEO of PCBAssemblyExpress. “This investment reflects our commitment to meeting the evolving needs of our customers and the industry as a whole. With our new facility, we are well-positioned to take on larger and more complex projects while maintaining the highest standards of quality and precision.”The new facility also aligns with PCBAssemblyExpress’s dedication to sustainability and environmentally responsible practices. The company has implemented eco-friendly initiatives throughout the facility, such as waste reduction and energy-efficient systems, to minimize its environmental impact and contribute to a greener future.In addition to the new manufacturing facility, PCBAssemblyExpress has also expanded its range of services to include turnkey PCB assembly, prototype assembly, and consignment assembly. This comprehensive suite of services is designed to cater to the diverse needs of clients, from startups and small businesses to large multinational corporations.“Our goal is to be a one-stop solution for all PCB assembly needs, and our expanded service offerings reflect that commitment,” said [Insert Name]. “Our clients can now benefit from our expertise and capabilities across the entire spectrum of PCB assembly, from prototype development to full-scale production. We are dedicated to providing flexible, cost-effective solutions that meet our clients’ specific requirements and exceed their expectations.”With the launch of the new manufacturing facility and expanded service offerings, PCBAssemblyExpress is poised to further solidify its position as a leader in the PCB assembly industry. The company’s continued investment in technology, infrastructure, and talent underscores its determination to deliver exceptional value to its clients and contribute to the advancement of the electronics manufacturing sector.As PCBAssemblyExpress enters this new chapter of growth and innovation, the company remains steadfast in its pursuit of excellence and looks forward to serving existing and new clients with the same unwavering dedication and commitment to quality that has become its hallmark.

High Performance Flip Chip Resistor for Electronics Manufacturing

Flip Chip Resistor Market to Witness Robust Expansion by 2025The global Flip Chip Resistor market is anticipated to witness significant growth in the coming years, according to a new research report by [Company Name]. The report, titled "Flip Chip Resistor Market: Global Industry Analysis, Size, Share, Growth, Trends, and Forecast 2019-2025," offers a comprehensive analysis of the market, providing insights into the current trends and future opportunities.Flip Chip Resistor is a type of surface mount resistor that is widely used in various electronic devices and equipment. These resistors are preferred for their small size, high power rating, and low inductance, making them suitable for use in high-frequency and high-performance applications. The increasing demand for compact and high-performance electronic devices is expected to drive the growth of the Flip Chip Resistor market in the coming years.The report suggests that the global Flip Chip Resistor market is poised to grow at a substantial CAGR during the forecast period. The market is expected to be driven by the increasing adoption of electronic devices in various industries, including automotive, telecommunications, consumer electronics, and healthcare. The automotive industry, in particular, is expected to be a key driver for the growth of the Flip Chip Resistor market, as the demand for advanced electronic components in vehicles continues to rise.In terms of regional analysis, the report identifies Asia Pacific as a significant market for Flip Chip Resistors, owing to the presence of major electronics manufacturing hubs in countries such as China, Japan, and South Korea. The region is expected to witness substantial growth in the coming years, driven by the increasing demand for electronic devices and the growing investments in the electronics manufacturing sector.[Company Name] is a leading player in the global Flip Chip Resistor market, with a strong presence in key regions and a diverse product portfolio. The company offers a wide range of Flip Chip Resistors with varying specifications to meet the requirements of different applications and industries. With a focus on research and development, [Company Name] continues to innovate and introduce new products to cater to the evolving needs of the market.In addition to its product offerings, [Company Name] is also committed to providing exceptional customer service and support to its clients. The company's dedication to quality and reliability has earned it a strong reputation in the industry, making it a preferred choice for customers around the world.As the demand for electronic devices continues to grow, [Company Name] remains well-positioned to capitalize on the opportunities in the Flip Chip Resistor market. With its strong market presence, innovative products, and customer-focused approach, the company is expected to play a key role in driving the growth of the market in the coming years.The research report by [Company Name] provides valuable insights for industry stakeholders, including manufacturers, suppliers, distributors, and investors, to understand the current trends and future prospects of the Flip Chip Resistor market. As the market continues to evolve, [Company Name] is poised to play a pivotal role in shaping its trajectory and driving innovation in the industry.

Key Trends and Developments in the PCB Assembly Industry

The PCB Assembly Industry is currently experiencing significant growth due to technological advancements and increased demand for electronics in various sectors such as automotive, consumer electronics, healthcare, and industrial applications. As a key player in this industry, {} has been at the forefront of providing high-quality PCB assembly services to its clients.With state-of-the-art facilities and a team of experienced professionals, {} has established itself as a reliable partner for companies looking to outsource their PCB assembly needs. The company prides itself on its ability to deliver customized solutions that meet the unique requirements of each client, ensuring high-quality products that are delivered on time and within budget.The increasing complexity of electronic devices has led to a growing demand for advanced PCB assembly services. {} has been quick to adapt to these changes, investing in the latest technology and equipment to ensure that it stays ahead of the competition. This commitment to innovation has allowed the company to take on increasingly complex projects, ranging from small-scale prototypes to large-scale production runs.In addition to its focus on technological innovation, {} places a strong emphasis on quality control and assurance. The company's manufacturing processes adhere to the strictest industry standards, and each finished product undergoes rigorous testing to ensure its performance and reliability. This commitment to quality has earned {} a reputation for producing PCB assemblies of the highest caliber.Furthermore, {} has cultivated strong relationships with its suppliers, allowing for efficient procurement of materials and components. This, in turn, enables the company to offer competitive pricing and quick turnaround times, further solidifying its position as a leading player in the PCB assembly industry.As the demand for PCB assembly services continues to rise, {} is well-positioned to capitalize on this growth. The company has plans to further expand its production capacity and enhance its capabilities, allowing it to take on even more challenging projects in the future. By staying abreast of industry trends and investing in its infrastructure, {} is poised to remain a key player in the PCB assembly industry for years to come.In conclusion, the PCB assembly industry is experiencing rapid growth, driven by technological advancements and increasing demand for electronic devices. {} has positioned itself as a leader in this industry, offering high-quality, customized PCB assembly services to its clients. With a focus on innovation, quality, and efficiency, the company is well-equipped to capitalize on the growing demand for PCB assembly services and maintain its position as a key player in the industry.

What is a Black PCB Board and How is it Used?

Black PCB Board: The Latest Innovation by a Leading Electronics CompanyIn the world of electronics, innovation and quality are paramount. The rapidly evolving technology landscape demands cutting-edge solutions that not only meet current needs but also anticipate the future. One company that has continually demonstrated its commitment to excellence and innovation is [remove brand name]. Renowned for its high-quality electronic components and exceptional products, [brand name] has recently unveiled its latest innovation: the Black PCB Board.The Black PCB Board is a groundbreaking development in the field of electronics. As the heart and soul of any electronic device, the printed circuit board (PCB) plays a crucial role in ensuring the proper functioning of electronic components. What sets the Black PCB Board apart is its unique design and construction, offering superior performance and reliability.[Brand name] has a rich history of delivering state-of-the-art electronic solutions to its customers. With a focus on research and development, the company has consistently pushed the boundaries of innovation, leading to the creation of cutting-edge products that have set new industry standards. The introduction of the Black PCB Board is yet another testament to [brand name]'s unwavering commitment to excellence and pioneering technology.The Black PCB Board boasts a number of key features that set it apart from traditional PCBs. The board is designed to provide enhanced electrical performance, making it ideal for demanding applications where precision and reliability are essential. Its black color not only adds to its aesthetic appeal but also serves a practical purpose by reducing the potential for signal interference and crosstalk.In addition to its superior performance, the Black PCB Board is built to withstand the rigors of various operating environments. Its robust construction and durable materials ensure long-term reliability, making it a preferred choice for a wide range of electronic applications. Whether used in consumer electronics, automotive systems, industrial equipment, or aerospace technology, the Black PCB Board delivers uncompromising performance.Furthermore, [brand name] has incorporated advanced manufacturing techniques and rigorous quality control measures to ensure that every Black PCB Board meets the highest standards. The company's state-of-the-art facilities and experienced engineering team are dedicated to producing PCBs of the utmost quality, setting a new benchmark in the industry.The launch of the Black PCB Board underscores [brand name]'s continued dedication to innovation and customer satisfaction. By providing a superior product that meets the ever-evolving demands of the electronics industry, the company reinforces its position as a leader in the field. Customers can trust [brand name] to deliver cutting-edge solutions that empower their own products and technologies.In conclusion, the introduction of the Black PCB Board by [brand name] marks a significant milestone in the world of electronics. With its exceptional performance, durability, and reliability, this innovative PCB sets a new standard for electronic components. As [brand name] continues to push the boundaries of innovation, customers can expect to benefit from groundbreaking technologies that redefine the industry. The Black PCB Board is a testament to [brand name]'s unwavering commitment to excellence and its relentless pursuit of innovative solutions.

Top Tips for Assembling PCB SMT for Efficient Manufacturing

Assembled PCB SMT plays a crucial role in the manufacturing of various electronic devices and products. With the advancements in technology, there is an increasing demand for reliable and high-quality PCB assembly services. One company that has been making waves in this industry is {}. {} is a leading electronic manufacturing services company specializing in PCB assembly and SMT (Surface Mount Technology) assembly. The company offers a wide range of services including PCB layout, prototyping, and full production runs. With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, {} has established itself as a trusted partner for businesses across various industries.The process of assembling PCBs using SMT involves placing electronic components directly onto the surface of the printed circuit board. This method is known for its efficiency and precision, allowing for higher component density and faster production times. {} has invested in the latest SMT equipment and technology to ensure that their PCB assemblies meet the highest quality standards.One of the key advantages of SMT assembly is its ability to accommodate smaller and lighter electronic components, making it ideal for compact and lightweight devices. {} understands the importance of keeping up with the latest technological advancements, and their SMT assembly services reflect their commitment to staying ahead of the curve.In addition to SMT assembly, {} also offers through-hole assembly, box build assembly, and testing services. This comprehensive approach allows the company to cater to the diverse needs of their clients, from initial design and prototyping to full-scale production and testing.The company serves a wide range of industries including automotive, telecommunications, aerospace, consumer electronics, and medical devices. Their expertise in PCB assembly and SMT assembly has earned them a reputation for delivering reliable and high-quality electronic manufacturing services.With a focus on continuous improvement and customer satisfaction, {} has implemented strict quality control measures at every stage of the manufacturing process. From initial design validation to final product testing, the company adheres to stringent quality standards to ensure that their PCB assemblies meet the highest level of performance and reliability.Furthermore, {} is committed to environmental sustainability and adheres to industry best practices for waste management and resource conservation. By implementing green manufacturing initiatives, the company strives to minimize its environmental footprint while delivering top-notch electronic manufacturing services.As a leading player in the electronic manufacturing services industry, {} continues to expand its capabilities and capacity to meet the evolving demands of the market. The company's dedication to innovation and excellence has positioned them as a preferred partner for businesses seeking reliable and high-quality PCB assembly and SMT assembly services.In conclusion, Assembled PCB SMT is a critical component in the production of electronic devices, and {}. stands out as a renowned electronic manufacturing services provider. With a strong focus on quality, innovation, and customer satisfaction, the company is well-equipped to meet the diverse needs of clients across various industries. As technology continues to advance, {} remains at the forefront of the industry, delivering cutting-edge PCB assembly and SMT assembly services.

High-Quality PCB Board for Routers: A Comprehensive Guide

The demand for high-quality router PCB boards is on the rise as more and more industries rely on efficient and reliable networking solutions. One company that has been at the forefront of providing top-notch router PCB boards is [Need to remove brand name].With a strong reputation for delivering cutting-edge technology and exceptional customer service, [Company name] has become a trusted name in the industry. The company takes pride in its ability to design and manufacture PCB boards that meet the highest standards of quality and performance.[Company name] has a team of highly skilled engineers and technicians who are dedicated to creating innovative and reliable router PCB boards. They utilize the latest technologies and techniques in their manufacturing processes to ensure that each board meets the exact specifications and requirements of their clients.The router PCB boards produced by [Company name] are known for their exceptional durability and reliability. They are designed to withstand the rigors of constant use and provide consistent performance in even the most demanding environments. These boards are essential components in a wide range of networking applications, from small office setups to large-scale industrial systems.In addition to their technical expertise, [Company name] also prides itself on its commitment to customer satisfaction. The company offers personalized service and support to ensure that each client receives the right router PCB board for their specific needs. Whether it's a custom design or a standard product, [Company name] works closely with its clients to deliver the best possible solution.Furthermore, [Company name] is dedicated to upholding the highest standards of quality and reliability in its products. The company follows strict quality control measures throughout the manufacturing process to ensure that each router PCB board meets or exceeds industry standards. This commitment to quality has earned [Company name] a reputation for excellence and reliability in the industry.As the demand for router PCB boards continues to grow, [Company name] is well-positioned to meet the needs of its clients. The company is constantly innovating and evolving its products to keep pace with the rapidly changing technology landscape. With a focus on performance, reliability, and customer satisfaction, [Company name] is a leading provider of router PCB boards for a wide range of industries.In conclusion, [Company name] is a company that has established itself as a premier provider of high-quality router PCB boards. With a strong focus on innovation, reliability, and customer satisfaction, the company has earned the trust and respect of its clients in the industry. As the demand for reliable networking solutions continues to grow, [Company name] is well-positioned to meet the needs of its clients with its top-notch router PCB boards.

Top 5 Tips for Designing a Telecom R&D PCB for Improved Performance

Telecom R&D PCB, a leading provider of advanced printed circuit board solutions for the telecommunications industry, has recently announced the introduction of their new cutting-edge technology.The company, which has been at the forefront of PCB development for over a decade, has a reputation for delivering high-quality products to telecom companies around the world. With a focus on innovation and reliability, Telecom R&D PCB has earned the trust of their customers and has become a reputable name in the industry.The introduction of their latest technology represents a significant advancement in the field of telecommunications PCBs. This new technology is designed to meet the increasing demands of the telecom industry, offering enhanced performance and reliability for mission-critical applications.Telecom R&D PCB's new technology boasts several key features that set it apart from traditional PCB solutions. It offers improved signal integrity, lower power consumption, and higher data speeds, making it an ideal choice for next-generation telecom equipment.In addition, the new technology also incorporates advanced thermal management techniques, ensuring that the PCB can withstand the rigors of demanding telecom environments. This not only extends the lifespan of the equipment but also reduces the risk of downtime and maintenance costs for telecom operators.Furthermore, the new technology is designed to meet the industry's stringent quality and reliability standards. Telecom R&D PCB has invested heavily in research and development to ensure that their products deliver consistent performance in the field. This commitment to quality has made them a trusted partner for telecom companies looking for reliable PCB solutions.The introduction of this new technology comes at a crucial time for the telecommunications industry, as it continues to evolve and expand with the rollout of 5G networks and the increasing demand for high-speed data services. Telecom R&D PCB's cutting-edge technology is well-positioned to meet these evolving needs and provide telecom companies with the tools they need to stay competitive in the market."We are excited to introduce our latest technology to the telecommunications industry," said a spokesperson for Telecom R&D PCB. "This new technology represents the culmination of years of research and development, and we believe it will play a crucial role in advancing the capabilities of telecom equipment. We are confident that our customers will see significant benefits from integrating this technology into their products."Telecom R&D PCB's commitment to innovation and quality has positioned them as a leader in the telecom industry. Their latest technology represents a significant leap forward in the field of telecommunications PCBs and is poised to make a lasting impact on the industry.With their new technology, Telecom R&D PCB continues to demonstrate their dedication to meeting the evolving needs of telecom companies and providing them with the tools they need to succeed in a rapidly changing market. As the telecom industry continues to push the boundaries of what is possible, Telecom R&D PCB is well-equipped to support their customers with reliable and advanced PCB solutions to drive their success.

The Importance of Professional PCBA Services for Your PCB Assembly Needs

PCB Assembly (PCBA) is an essential part of the electronics manufacturing process. PCBA refers to the process of assembling electronic components onto a printed circuit board (PCB). This process involves soldering the components onto the PCB to create a functional electronic device. {Company Name} is a leading provider of PCB Assembly (PCBA) services. They specialize in providing high-quality, cost-effective solutions for a wide range of industries including telecommunications, automotive, consumer electronics, and more. With state-of-the-art facilities and a team of highly skilled technicians, {Company Name} is well-equipped to handle complex PCBA projects with precision and efficiency.The process of PCBA involves several key steps including component placement, soldering, inspection, and testing. {Company Name} utilizes advanced equipment and technologies to ensure that each step of the process is carried out with the utmost accuracy and quality. Their team of experts is trained to identify and address any potential issues that may arise during the assembly process, ensuring that the final product meets the highest standards of quality and reliability.In addition to their technical expertise, {Company Name} is committed to providing exceptional customer service. They work closely with their clients to understand their specific requirements and provide tailored solutions to meet their needs. Whether it's a small prototype project or a large-scale production run, {Company Name} is dedicated to delivering results that exceed expectations.Furthermore, {Company Name} places a strong emphasis on quality control and assurance. They adhere to strict quality standards and protocols to ensure that each PCBA project meets the industry's highest standards. This commitment to quality has earned them a reputation as a trusted partner for many leading companies in the electronics industry.One of {Company Name}'s key strengths lies in their ability to adapt to the ever-evolving demands of the electronics market. They continuously invest in research and development to stay at the forefront of industry trends and technological advancements. This proactive approach enables them to offer innovative solutions and stay ahead of the competition.As a responsible corporate citizen, {Company Name} is also deeply committed to sustainability and environmental responsibility. They employ eco-friendly practices in their manufacturing processes and strive to minimize their environmental impact. This commitment to sustainability not only benefits the environment but also reflects their dedication to operating with integrity and social responsibility.In conclusion, {Company Name} is a trusted provider of high-quality PCB Assembly (PCBA) services. Their technical expertise, commitment to quality, and dedication to customer satisfaction set them apart in the highly competitive electronics manufacturing industry. With a focus on innovation and sustainability, {Company Name} is well-positioned to meet the evolving needs of their clients and continue to be a leader in the field of PCBA.

Effective Techniques for Soldering SMD Parts: A Comprehensive Guide

{} is proud to announce the launch of their latest innovation in the field of electronics manufacturing, the SMD parts soldering machine. The new machine is set to revolutionize the way SMD parts are soldered, making the process faster, more efficient, and more precise than ever before.SMD (Surface Mount Device) parts are a crucial component in modern electronics manufacturing, used in everything from smartphones and laptops to medical devices and automotive components. Soldering these tiny components onto circuit boards has traditionally been a labor-intensive and time-consuming process, requiring skilled workers to manually position and solder each part.The new SMD parts soldering machine from {} is set to change all that. Using advanced robotic technology, the machine is capable of automatically picking, placing, and soldering SMD parts with incredible precision and speed. This not only saves time and labor costs for manufacturers, but also ensures a higher level of accuracy and consistency in the soldering process.The machine is designed to be easy to operate, with a user-friendly interface that allows operators to quickly set up and program the machine for different types of SMD parts. This makes it suitable for a wide range of manufacturing applications, from small-scale prototyping to large-scale production.In addition to its speed and precision, the machine is also designed with safety in mind. It features advanced safety features to protect both the machine and its operators, ensuring peace of mind for manufacturers and workers alike.The launch of the SMD parts soldering machine is the latest in a long line of innovations from {}. Since its founding, the company has been at the forefront of electronic manufacturing technology, continually pushing the boundaries of what is possible in the industry.With a team of experienced engineers and a commitment to research and development, {} has earned a reputation for delivering high-quality, reliable solutions to the electronics manufacturing market. The company is dedicated to providing its customers with the tools they need to stay competitive in a rapidly evolving industry, and the SMD parts soldering machine is a perfect example of that commitment.The launch of the new machine is set to have a significant impact on the electronics manufacturing industry. By streamlining the process of soldering SMD parts, it has the potential to save manufacturers time and money, while also improving the overall quality of the finished products.In addition, the machine is expected to open up new possibilities for innovation in electronics design, by making it easier to work with smaller and more complex SMD components. This will allow manufacturers to create more advanced and sophisticated electronic products, driving progress and innovation in the industry as a whole.Overall, the launch of the SMD parts soldering machine represents a significant milestone for {}. It is a testament to the company's dedication to excellence and innovation, and it is sure to have a lasting impact on the electronics manufacturing industry.As the industry continues to evolve and grow, {} remains committed to staying at the forefront of technological advancements, and the new SMD parts soldering machine is just the latest example of that commitment. With its speed, precision, and ease of use, the machine is set to become an essential tool for electronics manufacturers around the world, helping them to stay ahead of the competition and continue pushing the boundaries of what is possible in electronic design and manufacturing.

Complete Guide to Through Hole PCB Assembly: Process and Benefits

Through Hole PCB Assembly has become an essential process in the manufacturing industry. It involves the placement of components through holes on a printed circuit board (PCB), which are then soldered to create a secure connection. This process is crucial for creating reliable and durable electronic devices such as industrial machinery, medical equipment, and consumer electronics.{Company} has been a leader in the PCB assembly industry for over a decade, specializing in providing high-quality through hole assembly services to a wide range of clients. With state-of-the-art manufacturing facilities and a team of experienced professionals, {Company} has established a strong reputation for delivering top-notch PCB assembly solutions.The through hole PCB assembly process begins with the preparation of the PCB, which involves drilling holes and applying a layer of copper to create the circuit pathways. Once the PCB is ready, the components are placed through the holes according to the design specifications. This requires precision and accuracy to ensure that the components are aligned correctly and securely in place.{Company} utilizes advanced automated equipment and meticulous quality control measures to ensure that the through hole assembly is performed with the highest level of precision and efficiency. This allows for the production of PCBs with consistent quality and reliability, meeting the stringent requirements of various industries.One of the key advantages of through hole PCB assembly is its ability to handle high-power and high-current applications. Through hole components are typically larger and have stronger connections compared to surface mount components, making them ideal for applications that require robust electrical connections and mechanical stability.{Company} has a diverse portfolio of clients, ranging from small businesses to large corporations, and serves a wide range of industries including aerospace, automotive, telecommunications, and defense. The company's commitment to excellence and customer satisfaction has earned them a loyal customer base and a reputation for delivering reliable, high-quality PCB assembly solutions.In addition to through hole PCB assembly, {Company} also offers a comprehensive range of services including surface mount assembly, PCB design and layout, prototype assembly, and testing. This allows clients to benefit from a one-stop solution for all their PCB assembly needs, streamlining the production process and reducing time-to-market.{Company}'s dedication to innovation and continuous improvement has driven the development of cutting-edge assembly techniques and technologies. Their investment in research and development has allowed them to stay ahead of industry trends and customer demands, while maintaining a competitive edge in the market.As the demand for high-quality through hole PCB assembly continues to grow, {Company} remains committed to providing superior services that meet the evolving needs of the industry. With a focus on quality, precision, and efficiency, {Company} is well-positioned to continue its success as a leading provider of PCB assembly solutions.In conclusion, through hole PCB assembly is a critical process for the manufacturing of reliable and durable electronic devices. {Company} has established itself as a trusted leader in the industry, delivering top-notch through hole assembly services to a diverse range of clients. With a focus on innovation, quality, and customer satisfaction, {Company} is poised to maintain its position at the forefront of the PCB assembly industry for years to come.