DIY Logo Stencil Creation: Step-by-Step Guide and Tips

By:Admin

With a team of experienced designers and state-of-the-art technology, Create Logo Stencil (need remove brand name) is able to produce detailed and accurate stencils that effectively capture the essence of a brand’s logo. Whether a business is looking to create a temporary promotional display or a more permanent branding solution, the company offers a range of stencil materials and sizes to suit different needs.

In addition to providing standard logo stencils, Create Logo Stencil (need remove brand name) also offers custom stencil design services. This allows businesses to create unique and personalized stencils that align with their branding and marketing objectives. The company’s design team works closely with clients to understand their vision and develop bespoke stencil solutions that make a lasting impression on their target audience.

Create Logo Stencil (need remove brand name)’s commitment to quality and customer satisfaction is evident in its attention to detail and dedication to delivering exceptional results. The company takes pride in its ability to produce stencils that accurately represent a brand’s identity and effectively communicate its message. This has earned Create Logo Stencil (need remove brand name) a loyal customer base and a reputation for excellence in the industry.

In addition to its standard and custom stencil offerings, Create Logo Stencil (need remove brand name) also provides stencil painting services for businesses that require assistance with the application of their stencils. The company’s team of skilled painters ensures that stencils are applied accurately and professionally, resulting in a polished and professional finish.

Create Logo Stencil (need remove brand name)’s stencils have been used by a wide range of businesses across various industries, including retail, hospitality, and events. Whether it’s for a temporary promotion, a special event, or a permanent branding solution, the company’s stencils offer a cost-effective and impactful way to enhance a brand’s visibility and reach its target audience.

As businesses continue to seek innovative and attention-grabbing ways to promote their brand, Create Logo Stencil (need remove brand name)’s logo stencils provide a versatile and effective marketing tool. With their ability to create striking and memorable visuals, these stencils offer businesses a unique opportunity to differentiate themselves and leave a lasting impression on their customers.

In conclusion, Create Logo Stencil (need remove brand name) is a trusted provider of high-quality logo stencils that help businesses elevate their branding and marketing efforts. With its focus on quality, customization, and customer satisfaction, the company has established itself as a leader in the industry and a go-to source for businesses looking to make a lasting impact with their branding. Whether for temporary promotions or permanent branding solutions, Create Logo Stencil (need remove brand name)’s stencils offer a versatile and impactful way to showcase a brand’s identity and message.

Company News & Blog

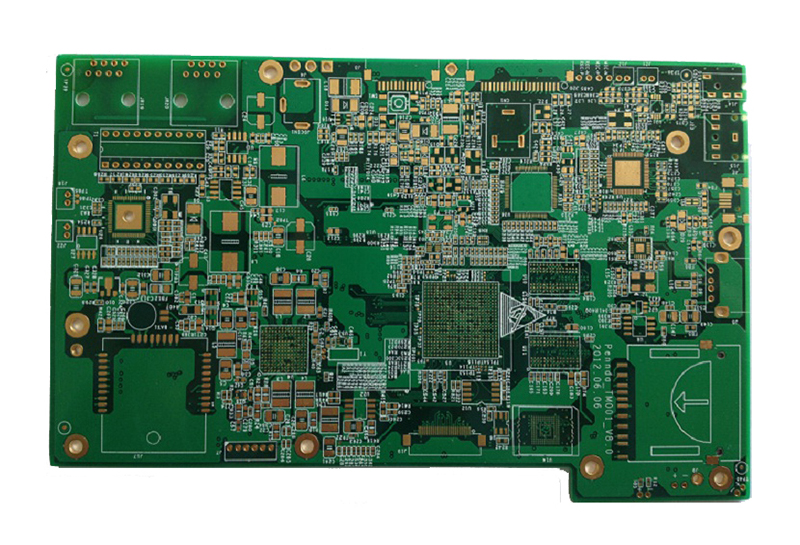

Flashing Printed Circuit Board: What You Need to Know

Flashing PCB, a leading provider of cutting-edge printed circuit board (PCB) solutions, has recently made a significant impact in the electronics industry with their latest innovation. The company has been at the forefront of PCB manufacturing and assembly for over a decade, and their commitment to quality and innovation has solidified their reputation as a trusted industry leader.Flashing PCB's new product, which utilizes advanced technology to enhance performance and reliability, comes at a time when the demand for high-quality PCBs is greater than ever. With the rapid advancement of technology in various industries, there is an increasing need for PCBs that can keep up with the high demands of modern electronic devices. Flashing PCB's latest innovation is set to meet these demands and provide customers with a solution that exceeds expectations.The company's dedication to providing top-of-the-line PCB solutions is evident in their state-of-the-art manufacturing facilities and their team of highly skilled engineers and technicians. Flashing PCB maintains strict quality control measures throughout the production process to ensure that every single PCB that leaves their facility meets the highest standards. This commitment to excellence has earned them a loyal customer base and has positioned them as a preferred partner for many businesses in need of high-quality PCB solutions.In addition to their commitment to quality, Flashing PCB also places a strong emphasis on innovation. They continuously invest in research and development to stay ahead of the curve and to anticipate the evolving needs of their customers. The result is a product lineup that is not only cutting-edge but also versatile and adaptable to a wide range of applications.Flashing PCB's latest innovation is a testament to their dedication to pushing the boundaries of what is possible in the realm of PCB technology. By leveraging their expertise and experience, they have developed a product that offers unparalleled performance and reliability, setting a new standard for the industry.The new product is designed to address the challenges of modern electronics, including high-speed data processing, complex circuitry, and miniaturization. Its advanced design and construction make it an ideal solution for a wide range of applications, from consumer electronics to industrial equipment.One of the key features of the new product is its enhanced durability and resistance to environmental factors. This makes it well-suited for use in harsh operating conditions, where traditional PCBs may struggle to perform reliably. Additionally, the product's high-speed capabilities make it ideal for applications that require rapid data processing and transmission.Flashing PCB's latest innovation is already generating a significant buzz in the industry, with early adopters praising its performance and reliability. Customers who have had the opportunity to test the product have reported impressive results, citing its ability to meet and exceed their expectations.As the demand for high-quality PCB solutions continues to grow, Flashing PCB's new product is set to make a significant impact on the industry. Its advanced features and unmatched performance make it a game-changer for businesses seeking to stay ahead of the competition and deliver superior products to their customers.With their track record of excellence and their commitment to innovation, Flashing PCB is well-positioned to solidify their position as an industry leader and preferred partner for businesses in need of high-quality PCB solutions. Their latest innovation is a testament to their dedication to pushing the boundaries of what is possible in the world of PCB technology, and it is sure to set a new standard for the industry as a whole.

What are Active and Passive Circuits? Understanding the Difference

Active And Passive Circuit, a leading provider of electronic components and circuit solutions, has recently announced the launch of their latest product line aimed at enhancing the performance and efficiency of electronic circuits. The company, known for its innovative approach and high-quality products, is committed to providing solutions that meet the evolving needs of the electronic industry.The new product line includes a range of active and passive components designed to optimize circuit performance and reliability. Active components such as transistors, integrated circuits, and diodes are essential for controlling the flow of electricity within a circuit. These components are crucial for amplifying signals, switching signals on and off, and controlling the flow of current.Passive components, on the other hand, do not require an external power source to operate and include resistors, capacitors, and inductors. These components are crucial for storing and managing energy within a circuit, as well as for regulating the flow of current.As electronic circuits continue to become more complex and demanding, the need for high-quality active and passive components has become increasingly important. Active And Passive Circuit understands the challenges faced by electronic engineers and designers and is dedicated to providing solutions that address these challenges.With a team of experienced engineers and technical experts, Active And Passive Circuit is committed to designing and manufacturing components that meet the highest standards of quality and performance. The company's dedication to research and development ensures that their products are at the forefront of technological advancements, enabling customers to stay ahead in the rapidly changing electronic industry.One of the key advantages of Active And Passive Circuit's products is their reliability and durability. The components are rigorously tested to ensure that they can withstand the demands of various applications and environments. This level of quality assurance gives customers the confidence that their electronic circuits will perform consistently and dependably.Moreover, Active And Passive Circuit prides itself on its commitment to sustainability and environmental responsibility. The company adheres to strict manufacturing processes that minimize waste and reduce the environmental impact of their operations. This dedication to sustainability has earned Active And Passive Circuit a reputation as a responsible and ethical provider of electronic components.The launch of the new product line is expected to further solidify Active And Passive Circuit's position as a trusted partner for electronic engineers and designers. By offering a comprehensive range of active and passive components, the company aims to simplify the design and development process for its customers, ultimately saving them time and resources."We are excited to introduce our latest product line, which represents a significant step forward in our commitment to providing high-quality solutions for electronic circuits," said a spokesperson for Active And Passive Circuit. "Our team has worked tirelessly to develop these components, and we are confident that they will meet the needs of our customers and help them achieve their design goals."As the electronic industry continues to evolve, the demand for reliable and efficient active and passive components will only continue to grow. With its latest product line, Active And Passive Circuit is well-positioned to meet this demand and continue to be a leader in the electronic components market.

High-Quality Circuit Board PCBA Services for Your Electronic Devices

Circuit Board PCBA: Revolutionizing Electronic ManufacturingIn today's fast-paced world, electronic devices play a pivotal role in our daily lives. From smartphones and laptops to household appliances and industrial machinery, electronics are everywhere. Behind the seamless functioning of these devices lies the intricate work of circuit board PCBA (Printed Circuit Board Assembly), a critical component in electronic manufacturing. PCBA, also known as a circuit board assembly, is a fundamental part of electronic equipment. It comprises various electronic components such as resistors, capacitors, and integrated circuits that are mounted onto a bare circuit board. These components are then soldered to create a functional electronic assembly that forms the backbone of modern devices. As technology evolves, the demand for more advanced and efficient PCBA has become increasingly important.One company that has been making significant strides in the field of PCBA is {Company Name}. {Company Name} is a leading provider of advanced electronic manufacturing services, specializing in PCB assembly, including circuit board PCBA. With state-of-the-art facilities and a team of highly skilled engineers and technicians, {Company Name} has carved a niche for itself in the electronics industry.Founded in {Year}, {Company Name} has focused on delivering high-quality, reliable, and cost-effective solutions to its clients worldwide. With a customer-centric approach and a strong emphasis on innovation, {Company Name} has built a reputation for being a trusted partner in the electronic manufacturing industry. The company's commitment to research and development has enabled it to stay ahead of the curve in providing cutting-edge PCBA solutions to meet the evolving needs of its clients.{Company Name} offers a comprehensive range of PCBA services, including prototype assembly, small to medium volume production, and full turnkey solutions. The company's expertise in surface mount technology (SMT), through-hole assembly, and testing ensures that it can cater to a diverse set of requirements, from simple to highly complex electronic assemblies. With a focus on quality assurance and compliance with industry standards, {Company Name} has emerged as a preferred choice for companies looking for reliable and efficient PCBA solutions.The advancement in PCBA technology has been a driving force behind the success of {Company Name}. The company has embraced the latest manufacturing techniques, including automated assembly processes and advanced testing methodologies, to ensure the highest level of precision and reliability in its PCBA offerings. By staying abreast of industry trends and investing in cutting-edge equipment, {Company Name} has been able to streamline its production processes and deliver superior PCBA solutions to its clients.One of the key differentiators for {Company Name} is its commitment to sustainability and environmental responsibility in its manufacturing practices. The company adheres to strict environmental standards and employs eco-friendly processes to minimize its carbon footprint. By adopting green manufacturing practices, {Company Name} not only contributes to a cleaner environment but also provides its clients with sustainable and socially responsible PCBA solutions.As the demand for electronic devices continues to grow, the role of PCBA in electronic manufacturing has become increasingly critical. Companies like {Company Name} are at the forefront of this evolution, driving innovation and efficiency in the PCBA space. With its dedication to quality, innovation, and sustainability, {Company Name} is poised to continue revolutionizing electronic manufacturing with its state-of-the-art circuit board PCBA solutions.

Complete Guide to Pcb Smt Process: Everything You Need to Know

In recent technology news, the innovative PCB SMT process is revolutionizing the electronics manufacturing industry. This advanced process, developed and implemented by the industry leader in electronics manufacturing, {}, is setting a new standard for efficiency and quality in PCB assembly.With over 20 years of experience in the industry, {} has been at the forefront of developments in printed circuit board (PCB) manufacturing and surface mount technology (SMT). The company has a strong reputation for delivering high-quality electronic products to a wide range of industries, including automotive, aerospace, telecommunications, and consumer electronics.The PCB SMT process developed by {} is a game-changer in the electronics manufacturing industry. It involves the use of surface mount technology to directly place electronic components onto the surface of a printed circuit board. This process differs from traditional methods, such as through-hole technology, where components are inserted into holes on the circuit board.One of the key advantages of the PCB SMT process is its ability to significantly reduce the size of electronic devices while increasing their functionality and performance. By directly mounting components onto the surface of the PCB, manufacturers can produce smaller, lighter, and more efficient electronic products.Additionally, the PCB SMT process allows for higher component density and greater design flexibility, enabling manufacturers to create more complex and sophisticated electronic devices. This is particularly important in the rapidly evolving technology industry, where consumers are demanding smaller, more powerful, and more feature-rich products.Furthermore, the PCB SMT process offers improved reliability and durability compared to traditional PCB assembly methods. By eliminating the need for holes in the circuit board, the risk of mechanical and electrical failures is reduced, leading to longer-lasting and more robust electronic products.In addition to these benefits, the PCB SMT process also enables faster and more cost-effective production. By streamlining the assembly process and reducing the need for manual labor, manufacturers can significantly reduce lead times and production costs, ultimately making electronic products more affordable for consumers.{}'s expertise and commitment to innovation have positioned the company as a leading provider of PCB SMT solutions. With state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians, {} is able to deliver superior quality products and services to meet the diverse needs of its customers.The company's dedication to research and development has led to the continuous improvement and refinement of the PCB SMT process, ensuring that it remains at the forefront of technological advancements in electronic manufacturing. This commitment to excellence has earned {} a strong reputation as a trusted partner for companies seeking high-quality electronic manufacturing solutions.As the demand for smaller, more powerful, and more reliable electronic products continues to grow, the PCB SMT process developed by {} is poised to play a crucial role in shaping the future of the electronics industry. With its numerous advantages, including increased functionality, improved reliability, and cost-effective production, the PCB SMT process represents a significant advancement in electronic manufacturing technology.In conclusion, the PCB SMT process developed by {} is a groundbreaking innovation that is transforming the way electronic products are designed and manufactured. With its numerous benefits, including smaller size, increased functionality, improved reliability, and cost-effective production, this process is revolutionizing the electronics industry and helping to meet the demands of the ever-evolving technology market. As {} continues to lead the way in electronic manufacturing, its PCB SMT process will undoubtedly play a pivotal role in shaping the future of electronic products.

Innovative Active Diode Circuit Technology: What You Need to Know

Active Diode Circuit (ADC) technology has been making waves in the electronics industry, and one company that is leading the way in this innovation is {}.{} is a global leader in semiconductor manufacturing and technology, specializing in the development of cutting-edge electronic components for a wide range of applications. With a strong focus on research and development, the company has been at the forefront of advancing semiconductor technology, and its latest breakthrough in ADC technology is set to revolutionize the industry.The Active Diode Circuit (ADC) is a novel electronic circuit that offers significant advantages over traditional diode circuits. By using active components such as transistors to control the behavior of diodes, ADC technology enables improved performance, efficiency, and reliability in electronic devices. This breakthrough has the potential to enhance the functionality of a wide range of electronic products, from smartphones and laptops to automotive systems and industrial equipment.{}’s proprietary ADC technology has been developed over several years of intensive research and testing, and the company holds multiple patents for its innovative circuit design. By leveraging its expertise in semiconductor manufacturing and design, {} has been able to produce ADC components that offer unmatched performance and reliability.One of the key benefits of {}’s ADC technology is its ability to improve energy efficiency in electronic devices. By actively controlling the behavior of diodes, ADCs can minimize power losses and improve the overall energy efficiency of electronic circuits. This is particularly important in today's electronic devices, where energy consumption is a growing concern for both consumers and manufacturers.In addition to energy efficiency, {}’s ADC technology also offers enhanced performance and reliability. By actively managing the behavior of diodes, ADCs can reduce signal distortion, improve signal integrity, and minimize the risk of component failure. This is particularly important in high-performance electronic products, where reliability and consistency are critical.{}’s ADC technology has already gained significant traction in the market, with several major electronics manufacturers incorporating ADC components into their latest products. From smartphones and tablets to automotive infotainment systems and industrial control equipment, ADC technology is poised to become a standard feature in a wide range of electronic devices.Looking ahead, {} is committed to further advancing ADC technology and exploring new applications for this innovative circuit design. With a dedicated team of engineers and researchers, the company is continuously pushing the boundaries of what is possible in semiconductor technology. By staying at the forefront of innovation, {} aims to cement its position as a global leader in semiconductor technology and continue to drive progress in the electronics industry.In conclusion, Active Diode Circuit (ADC) technology is poised to revolutionize the electronics industry, and {} is at the forefront of this innovation. With its proprietary ADC technology, the company is setting new standards for energy efficiency, performance, and reliability in electronic devices. As ADC technology continues to gain momentum in the market, {} is well-positioned to lead the way in shaping the future of semiconductor technology.

The Latest Advancements in Multilayer PCB Fabrication: What You Need to Know

In the world of advanced electronics and technology, the demand for multilayer PCB (Printed Circuit Board) fabrication has been growing rapidly. These PCBs are essential components in a wide range of devices, from smartphones and computers to medical equipment and automotive systems. As the need for smaller, more efficient, and high-performance electronic devices continues to rise, so does the demand for advanced PCB fabrication technology.One company that has been at the forefront of multilayer PCB fabrication is {}. With their state-of-the-art facilities and advanced manufacturing processes, they have been able to meet the growing demand for high-quality multilayer PCBs. The company has a long history of innovation and excellence in the field of electronic components and has become a trusted partner for many leading electronics manufacturers around the world.{} is committed to providing their customers with the highest quality multilayer PCBs, and they have invested heavily in their manufacturing facilities to achieve this goal. The company's production lines are equipped with advanced machinery and equipment to ensure precision and accuracy in the fabrication process. Their team of skilled engineers and technicians work tirelessly to maintain the highest standards of quality and reliability in every PCB they produce.One of the key advantages of multilayer PCBs is their ability to accommodate complex electronic circuits in a compact and efficient manner. This makes them an ideal choice for modern electronic devices that require high performance and reliability in a small form factor. With the capability to integrate multiple layers of conductive tracks and insulating layers, multilayer PCBs enable designers to create sophisticated electronic systems with greater flexibility and efficiency.The demand for multilayer PCB fabrication has been particularly strong in industries such as telecommunications, aerospace, automotive, and medical devices. These industries require high-performance electronic components that can withstand harsh operating conditions and operate reliably in critical applications. {} has been able to meet the stringent requirements of these industries by offering a wide range of multilayer PCBs that are designed to deliver superior performance and reliability.In addition to their commitment to quality and innovation, {} places a strong emphasis on environmental sustainability in their manufacturing processes. They have implemented stringent measures to minimize waste and reduce energy consumption in their facilities. The company also adheres to strict environmental regulations and standards to ensure that their operations have minimal impact on the environment.As the demand for advanced electronics continues to rise, {} is well-positioned to capitalize on the growing market for multilayer PCB fabrication. With their advanced manufacturing capabilities, commitment to quality and reliability, and focus on environmental sustainability, they have established themselves as a leading provider of multilayer PCBs in the global electronics industry.In conclusion, the demand for multilayer PCB fabrication continues to grow as electronic devices become increasingly advanced and sophisticated. With their advanced manufacturing facilities, strong commitment to quality, and focus on environmental sustainability, {} is well-equipped to meet the evolving needs of the electronics industry. Their dedication to innovation and excellence in PCB fabrication has made them a trusted partner for leading electronics manufacturers around the world, and they are well-positioned to continue driving the advancement of electronic technology for years to come.

High-Quality PCB Board for Routers: A Comprehensive Guide

The demand for high-quality router PCB boards is on the rise as more and more industries rely on efficient and reliable networking solutions. One company that has been at the forefront of providing top-notch router PCB boards is [Need to remove brand name].With a strong reputation for delivering cutting-edge technology and exceptional customer service, [Company name] has become a trusted name in the industry. The company takes pride in its ability to design and manufacture PCB boards that meet the highest standards of quality and performance.[Company name] has a team of highly skilled engineers and technicians who are dedicated to creating innovative and reliable router PCB boards. They utilize the latest technologies and techniques in their manufacturing processes to ensure that each board meets the exact specifications and requirements of their clients.The router PCB boards produced by [Company name] are known for their exceptional durability and reliability. They are designed to withstand the rigors of constant use and provide consistent performance in even the most demanding environments. These boards are essential components in a wide range of networking applications, from small office setups to large-scale industrial systems.In addition to their technical expertise, [Company name] also prides itself on its commitment to customer satisfaction. The company offers personalized service and support to ensure that each client receives the right router PCB board for their specific needs. Whether it's a custom design or a standard product, [Company name] works closely with its clients to deliver the best possible solution.Furthermore, [Company name] is dedicated to upholding the highest standards of quality and reliability in its products. The company follows strict quality control measures throughout the manufacturing process to ensure that each router PCB board meets or exceeds industry standards. This commitment to quality has earned [Company name] a reputation for excellence and reliability in the industry.As the demand for router PCB boards continues to grow, [Company name] is well-positioned to meet the needs of its clients. The company is constantly innovating and evolving its products to keep pace with the rapidly changing technology landscape. With a focus on performance, reliability, and customer satisfaction, [Company name] is a leading provider of router PCB boards for a wide range of industries.In conclusion, [Company name] is a company that has established itself as a premier provider of high-quality router PCB boards. With a strong focus on innovation, reliability, and customer satisfaction, the company has earned the trust and respect of its clients in the industry. As the demand for reliable networking solutions continues to grow, [Company name] is well-positioned to meet the needs of its clients with its top-notch router PCB boards.

Top Tips for Assembling PCB SMT for Efficient Manufacturing

Assembled PCB SMT plays a crucial role in the manufacturing of various electronic devices and products. With the advancements in technology, there is an increasing demand for reliable and high-quality PCB assembly services. One company that has been making waves in this industry is {}. {} is a leading electronic manufacturing services company specializing in PCB assembly and SMT (Surface Mount Technology) assembly. The company offers a wide range of services including PCB layout, prototyping, and full production runs. With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, {} has established itself as a trusted partner for businesses across various industries.The process of assembling PCBs using SMT involves placing electronic components directly onto the surface of the printed circuit board. This method is known for its efficiency and precision, allowing for higher component density and faster production times. {} has invested in the latest SMT equipment and technology to ensure that their PCB assemblies meet the highest quality standards.One of the key advantages of SMT assembly is its ability to accommodate smaller and lighter electronic components, making it ideal for compact and lightweight devices. {} understands the importance of keeping up with the latest technological advancements, and their SMT assembly services reflect their commitment to staying ahead of the curve.In addition to SMT assembly, {} also offers through-hole assembly, box build assembly, and testing services. This comprehensive approach allows the company to cater to the diverse needs of their clients, from initial design and prototyping to full-scale production and testing.The company serves a wide range of industries including automotive, telecommunications, aerospace, consumer electronics, and medical devices. Their expertise in PCB assembly and SMT assembly has earned them a reputation for delivering reliable and high-quality electronic manufacturing services.With a focus on continuous improvement and customer satisfaction, {} has implemented strict quality control measures at every stage of the manufacturing process. From initial design validation to final product testing, the company adheres to stringent quality standards to ensure that their PCB assemblies meet the highest level of performance and reliability.Furthermore, {} is committed to environmental sustainability and adheres to industry best practices for waste management and resource conservation. By implementing green manufacturing initiatives, the company strives to minimize its environmental footprint while delivering top-notch electronic manufacturing services.As a leading player in the electronic manufacturing services industry, {} continues to expand its capabilities and capacity to meet the evolving demands of the market. The company's dedication to innovation and excellence has positioned them as a preferred partner for businesses seeking reliable and high-quality PCB assembly and SMT assembly services.In conclusion, Assembled PCB SMT is a critical component in the production of electronic devices, and {}. stands out as a renowned electronic manufacturing services provider. With a strong focus on quality, innovation, and customer satisfaction, the company is well-equipped to meet the diverse needs of clients across various industries. As technology continues to advance, {} remains at the forefront of the industry, delivering cutting-edge PCB assembly and SMT assembly services.

Top High Power Inductor in 2023 - Ultimate Guide

High Power Inductor Innovations: A Game Changer in the Electronics IndustryIn today's fast-paced and technology-driven world, the demand for high-performance electronic components continues to rise. From consumer electronics to industrial applications, the need for reliable and efficient power management solutions has never been greater. This is where the High Power Inductor from {} comes into play - a revolutionary product that is set to change the game in the electronics industry.{} is a leading provider of innovative electronic components, specializing in power management solutions and magnetics. With a strong commitment to research and development, {} has continuously pushed the boundaries of technology to deliver cutting-edge products that meet the ever-evolving needs of the market.The High Power Inductor is the latest addition to the company's extensive portfolio of electronic components. Designed to address the growing demand for high-performance power management solutions, this innovative inductor offers a range of features and benefits that set it apart from traditional components in the market.One of the key highlights of the High Power Inductor is its exceptional power handling capabilities. With a high current rating and low electrical resistance, this inductor is capable of handling large amounts of power while maintaining optimum performance. This makes it an ideal choice for power supply applications, where efficiency and reliability are of utmost importance.Furthermore, the High Power Inductor is designed to operate at high frequencies, making it suitable for a wide range of applications in the electronics industry. Whether it's in switch-mode power supplies, automotive electronics, or industrial control systems, this inductor offers superior performance and stability across different operating conditions.Another notable feature of the High Power Inductor is its compact and robust design. Despite its high power handling capabilities, the inductor is engineered to be space-efficient, allowing for greater flexibility in design and integration. This is particularly beneficial for manufacturers looking to optimize the size and weight of their products without compromising on performance.Additionally, the High Power Inductor is built to withstand the most demanding environmental conditions, making it suitable for use in harsh operating environments. Its rugged construction and high-temperature tolerance ensure long-term reliability, making it an ideal choice for mission-critical applications in aerospace, defense, and industrial sectors.With the increasing focus on energy efficiency and sustainability, the High Power Inductor also offers significant advantages in terms of minimizing power losses and optimizing overall system performance. By leveraging advanced materials and manufacturing techniques, {} has been able to develop an inductor that delivers superior efficiency and helps reduce energy consumption in electronic systems.In line with {}'s commitment to quality and innovation, the High Power Inductor has undergone rigorous testing and validation to ensure compliance with industry standards and regulations. This includes comprehensive thermal, electrical, and mechanical testing, as well as environmental testing to validate its performance in real-world applications.In conclusion, the High Power Inductor from {} represents a significant milestone in the field of power management and magnetics. With its unparalleled power handling capabilities, high-frequency operation, compact design, and robust construction, this innovative inductor is set to revolutionize the way electronic systems are powered and managed.As the demand for high-performance electronic components continues to grow, the High Power Inductor is poised to play a crucial role in shaping the future of the electronics industry. With its ability to deliver exceptional performance, efficiency, and reliability, this inductor is a testament to {}'s relentless pursuit of excellence and its dedication to pushing the boundaries of technology.

Top 5 Tips for Increasing FPC Production in Your Manufacturing Facility

Global FPC (Flexible Printed Circuit) Market Expected to See GrowthThe global FPC (Flexible Printed Circuit) market is expected to see substantial growth in the coming years, with a CAGR of 8.5% projected from 2021 to 2026. FPCs are widely used in electronic devices such as smartphones, tablets, and wearables, and the increasing demand for these devices is a key driver for the growth of the FPC market.One leading company in the FPC market is {}, which has established itself as a key player in the production of high-quality FPCs. With a focus on innovation and customer satisfaction, {} has been able to differentiate itself from competitors and carve out a significant share of the global FPC market.{} has a strong track record in the production of FPCs, with a wide range of products that cater to the needs of various industries. The company's FPCs are known for their flexibility, reliability, and high performance, making them an ideal choice for manufacturers of electronic devices.In addition to its focus on product quality, {} also places a strong emphasis on sustainability and environmental responsibility. The company is committed to reducing its carbon footprint and minimizing waste, and it has implemented several initiatives to achieve these goals. As the global focus on sustainability continues to grow, {}'s commitment to environmental responsibility will likely be a key differentiator for the company in the FPC market.One of the key factors driving the growth of the FPC market is the increasing demand for consumer electronics. With the rise of smartphones, tablets, and wearables, there is a growing need for high-quality FPCs to enable the production of these devices. In addition, the automotive industry is also a significant contributor to the demand for FPCs, as modern vehicles incorporate a growing number of electronic components that rely on FPC technology.Another factor contributing to the growth of the FPC market is the ongoing development of 5G technology. The rollout of 5G networks around the world is driving the demand for advanced electronic devices, and FPCs are a crucial component in the production of these devices. As 5G technology continues to expand, the demand for FPCs is expected to grow accordingly.In terms of regional market trends, Asia-Pacific is expected to be a key growth market for FPCs. The region is home to some of the world's largest electronics manufacturers, and the increasing production of electronic devices in countries such as China, South Korea, and Japan is expected to drive the demand for FPCs. In addition, the growing adoption of 5G technology in Asia-Pacific is also expected to contribute to the growth of the FPC market in the region.Overall, the global FPC market is poised for significant growth in the coming years, driven by factors such as the increasing demand for consumer electronics, the development of 5G technology, and the focus on sustainability. Companies like {} are well-positioned to capitalize on these trends, thanks to their focus on product quality, innovation, and environmental responsibility. As the market for electronic devices continues to expand, the demand for high-quality FPCs is likely to grow accordingly, presenting exciting opportunities for companies in the FPC industry.