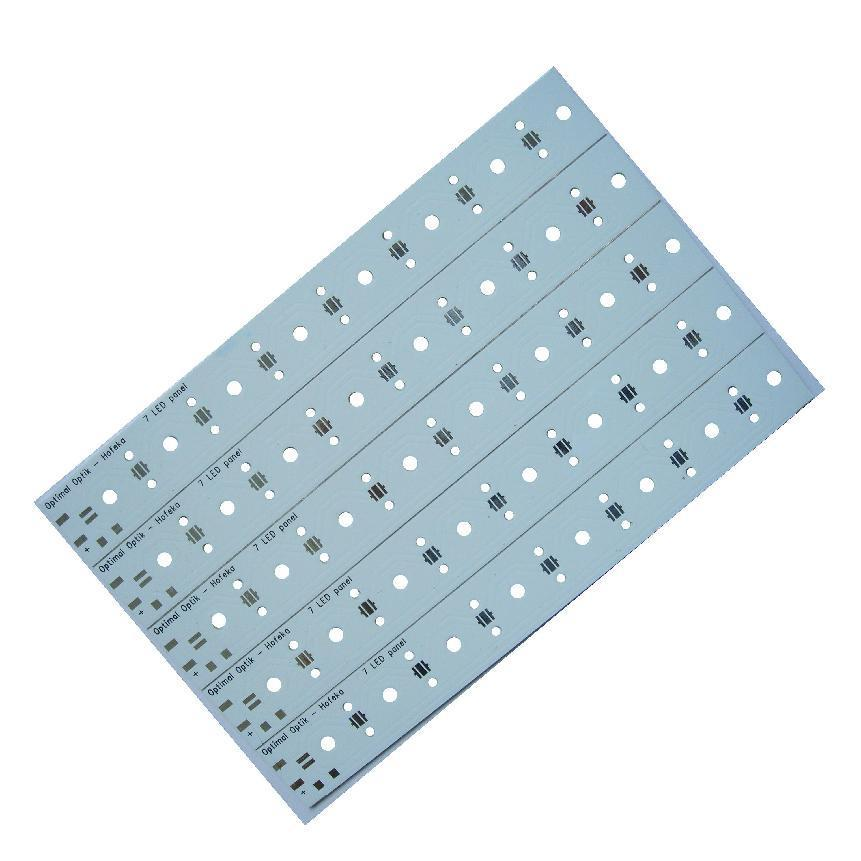

Complete Guide to Pcb Board Assembly: Everything You Need to Know

By:Admin

The new facility is equipped with the latest technology and machinery to ensure the highest level of precision and efficiency in the assembly process. From prototype to full production runs, Pcb Board Assembly has the capability to handle a wide range of project sizes and specifications. The facility also adheres to the highest quality standards and is certified to ISO [number] and [other relevant certifications].

"We are excited to open our new assembly facility, which represents a significant investment in our capabilities and capacity," said [Name], CEO of Pcb Board Assembly. "This expansion allows us to better serve our customers and meet the growing demand for our services. We are committed to providing superior quality and service to our clients, and this new facility is a reflection of that commitment."

In addition to its state-of-the-art facility, Pcb Board Assembly prides itself on its experienced team of engineers, technicians, and assembly specialists. The company's team is dedicated to providing personalized support and guidance to ensure that each project is completed to the highest standards. Whether it's a complex, high-density circuit board or a simple assembly job, Pcb Board Assembly has the expertise and resources to deliver results that exceed expectations.

Furthermore, Pcb Board Assembly places a strong emphasis on sustainability and environmental responsibility. The company has implemented various measures to reduce its carbon footprint and minimize waste in its manufacturing processes. This commitment to sustainable practices aligns with the company's values and reflects its dedication to being a responsible corporate citizen.

As a full-service electronic manufacturing partner, Pcb Board Assembly offers a comprehensive range of services, including PCB design and layout, component sourcing, PCB assembly, testing, and more. The company's capabilities cover a wide spectrum of industries, including aerospace, automotive, medical, telecommunications, and consumer electronics. With a focus on innovation and continuous improvement, Pcb Board Assembly is equipped to meet the evolving needs of the electronics manufacturing industry.

Customer satisfaction is at the core of Pcb Board Assembly's business philosophy. The company strives to build long-lasting relationships with its clients based on trust, integrity, and reliability. By understanding each client's unique requirements and challenges, Pcb Board Assembly is able to tailor its services to deliver custom solutions that drive success and competitiveness in the market.

"We take pride in the relationships we have built with our customers over the years," said [Name]. "Their success is our success, and we are dedicated to supporting them every step of the way. Our new assembly facility is just one example of our ongoing commitment to providing the best possible service to our clients."

In conclusion, Pcb Board Assembly's new assembly facility represents a significant milestone for the company and its commitment to excellence in electronic manufacturing. With its cutting-edge technology, experienced team, and unwavering dedication to customer satisfaction, Pcb Board Assembly is poised to continue its legacy as a leading provider of high-quality electronic manufacturing services.

Company News & Blog

Innovative Circuit Board Uses Bread Material for Sustainable Electronics

Bread Circuit Board: The Future of Electronic InnovationIn the world of electronic innovation, one company is making waves with its groundbreaking technology. (Company Name) has developed a revolutionary new product called the Bread Circuit Board, which promises to change the way we think about electronic design and production.The Bread Circuit Board is a game-changing innovation that offers a new approach to the design and creation of electronic devices. Unlike traditional circuit boards, the Bread Circuit Board is flexible, durable, and can be easily molded and shaped to fit a wide variety of applications. This versatility makes it an ideal choice for a wide range of industries, including consumer electronics, medical devices, automotive technology, and more.One of the key features of the Bread Circuit Board is its ability to be easily customized and reconfigured. This means that electronics manufacturers can easily adapt the board to suit their specific needs, whether that means creating a new product from scratch or modifying an existing design. This flexibility allows for faster prototyping and product development, ultimately saving time and money in the production process.The Bread Circuit Board is also incredibly durable, making it ideal for use in harsh environments. Its flexibility and strength make it resistant to shock, vibration, and extreme temperatures, making it an ideal choice for applications where traditional circuit boards might not hold up.In addition to its physical properties, the Bread Circuit Board also offers improved electrical performance over traditional circuit boards. The board's unique design allows for more efficient and reliable signal transmission, resulting in better overall performance for the devices it powers.In terms of sustainability, the Bread Circuit Board is also a game-changer. Its flexible and durable nature means that it can be easily recycled and reused, reducing waste and environmental impact in the electronics industry.The Bread Circuit Board has already garnered attention from industry leaders and innovators. Its potential to revolutionize electronic design and production has led to partnerships with major companies, and its technology is already being used in a wide range of cutting-edge products.The team at (Company Name) is proud to be at the forefront of this technological revolution. With their innovative approach to electronic design and production, they are paving the way for a new era of electronics that are more efficient, versatile, and sustainable.The development of the Bread Circuit Board is a testament to the company's commitment to pushing the boundaries of what is possible in electronic innovation. They are constantly striving to develop new and improved technologies that will shape the future of electronic design and production.As the electronics industry continues to evolve, the Bread Circuit Board stands out as a shining example of the innovative and forward-thinking approach that (Company Name) is known for. With their groundbreaking technology and dedication to excellence, they are poised to continue leading the way in the world of electronic innovation for years to come.

Top Active Components for Improved Performance: A Comprehensive Guide

Active Components, a leading provider of electronic components and solutions, has recently announced its expansion to new markets and the introduction of innovative products to meet the evolving needs of its customers.With a strong focus on research and development, Active Components has been at the forefront of technological advancements in the electronic components industry. The company has a proven track record of delivering high-quality products and reliable solutions to a wide range of industries, including automotive, aerospace, telecommunications, and consumer electronics.Active Components prides itself on its ability to anticipate market trends and engineering innovative solutions that address the changing needs of its customers. By leveraging its extensive industry expertise and dedicated team of professionals, the company has been able to stay ahead of the competition and maintain its position as a trusted partner for electronic components.One of the key factors contributing to the success of Active Components is its commitment to continuous improvement and the integration of cutting-edge technologies into its product offerings. The company's extensive product portfolio includes a wide range of electronic components such as microcontrollers, sensors, connectors, and power management solutions, all of which are designed to meet the stringent performance and reliability requirements of modern electronic systems.In line with its expansion efforts, Active Components has identified new market opportunities in emerging industries such as renewable energy, IoT (Internet of Things), and digital healthcare. By strategically aligning its product development and marketing efforts with these growing sectors, the company aims to further diversify its customer base and capitalize on the increasing demand for electronic components in these industries.Furthermore, Active Components has recently introduced a series of groundbreaking products that are poised to revolutionize the electronic components market. These new products leverage the latest advancements in materials science, manufacturing processes, and design technologies to deliver superior performance, enhanced reliability, and cost-effective solutions for its customers.To support its expansion and product development initiatives, Active Components has made significant investments in its manufacturing facilities, research laboratories, and talent acquisition. The company continues to foster a culture of innovation and collaboration, which enables its teams to explore new ideas, push the boundaries of technology, and deliver breakthrough solutions that address the most pressing challenges faced by its customers.In addition to its focus on innovation and expansion, Active Components remains committed to providing exceptional customer service and technical support to its clients. The company takes pride in its ability to build strong and long-lasting partnerships with its customers, understanding their unique requirements, and delivering tailored solutions that meet their specific needs.As Active Components continues to set new standards for quality and innovation in the electronic components industry, the company remains firmly committed to its core values of integrity, excellence, and customer satisfaction. By staying true to these principles and leveraging its technical expertise and industry insights, Active Components is well-positioned to achieve sustained growth and success in the global marketplace.In conclusion, Active Components' expansion efforts and the introduction of innovative products demonstrate the company's unwavering commitment to meeting the evolving needs of its customers and driving progress in the electronic components industry. With its strong focus on innovation, quality, and customer satisfaction, Active Components is poised to solidify its position as a leading provider of electronic components and solutions for years to come.

Dielectric Test: What It Is and How It Works

We are pleased to announce that our company has recently developed a cutting-edge Hipot Dielectric Test system, which is set to revolutionize the electrical testing industry. This innovative technology is the result of years of research and development, and we are proud to offer it to our clients as part of our comprehensive range of testing solutions.The Hipot Dielectric Test is a crucial part of the quality control process for electrical components and equipment. This test is designed to evaluate the insulation strength of a product by applying a high voltage to it and measuring the amount of current that is able to flow through the insulation. By subjecting an electrical component to a high voltage for a sustained period of time, the test can identify any potential weaknesses or defects in the insulation, helping to ensure the safety and reliability of the product.Our new Hipot Dielectric Test system is equipped with state-of-the-art technology that allows for highly accurate and reliable testing. It is capable of generating high voltages and measuring current with a high degree of precision, and its automated testing process ensures consistency and repeatability from test to test. This level of accuracy and reliability is essential for identifying even the smallest defects in insulation, and our system is designed to meet the most stringent quality standards.In addition to its advanced technology, our Hipot Dielectric Test system is also designed with user-friendliness in mind. The intuitive interface and easy-to-use controls make it simple for operators to set up and run tests, and the system is equipped with comprehensive safety features to protect operators and equipment during testing. This combination of advanced technology and user-friendly design makes our Hipot Dielectric Test system a valuable addition to any testing facility.Our company has a long history of providing high-quality testing solutions to a wide range of industries. We have established ourselves as a trusted partner for companies looking to ensure the quality and safety of their electrical products, and our commitment to innovation has allowed us to stay at the forefront of the industry. With the introduction of our new Hipot Dielectric Test system, we are proud to continue this tradition of excellence and to offer our clients the most advanced testing technology available.In addition to our new Hipot Dielectric Test system, we offer a comprehensive range of testing solutions to meet the needs of our clients. Our portfolio includes insulation resistance testing, ground continuity testing, and more, all of which are designed to help our clients ensure the safety and reliability of their electrical products. We also offer custom testing solutions to meet specific requirements, and our team of experts is dedicated to providing the highest level of support and service to our clients.We are confident that our new Hipot Dielectric Test system will set a new standard for electrical testing technology, and we are excited to offer this innovative solution to our clients. With its advanced technology, user-friendly design, and comprehensive support, our system is the ideal choice for companies looking to ensure the quality and safety of their electrical products. We are committed to continuing our tradition of excellence and innovation, and we look forward to helping our clients achieve their testing goals with our new Hipot Dielectric Test system.

How to Perform a DC Voltage Check with a Multimeter

The use of a multimeter for checking direct current (DC) voltage has become increasingly popular in various industries. With the advancement of technology, multimeters have become an essential tool for measuring and testing electrical circuits and components. The accuracy and reliability of a multimeter make it an indispensable instrument for electricians, engineers, and technicians. The ability to measure DC voltage is crucial for troubleshooting and diagnosing electrical systems, as well as for ensuring the safety and efficiency of electrical equipment.{Company Name} is a leading manufacturer of high-quality multimeters that are known for their accuracy, durability, and reliability. With a strong commitment to innovation and quality, {Company Name} has been at the forefront of developing advanced multimeters that meet the needs of professionals in various industries. The company's multimeters are designed to provide accurate measurements, user-friendly interface, and robust construction to withstand the rigors of everyday use.The DC voltage check feature in {Company Name}'s multimeters allows users to accurately measure the voltage in a DC circuit. This is essential for identifying electrical issues, troubleshooting problems, and ensuring the proper functioning of electrical systems. The multimeters are equipped with precise measurement capabilities, ensuring that users can obtain accurate voltage readings for their specific applications. With a wide range of voltage measurement options, {Company Name}'s multimeters are suitable for a variety of DC voltage testing requirements.One of the key advantages of using {Company Name}'s multimeters for DC voltage check is the reliability and accuracy of the measurements. The multimeters are equipped with high-quality components and advanced technology that ensure precise voltage readings, allowing users to make informed decisions about the condition of the electrical systems they are testing. This level of accuracy is crucial for preventing potential electrical hazards and maintaining the efficiency of electrical equipment.Furthermore, {Company Name}'s multimeters are designed with user convenience in mind, featuring easy-to-read displays, intuitive controls, and ergonomic designs. This makes them suitable for both experienced professionals and individuals who are new to electrical testing. The user-friendly interface enhances the overall testing experience, allowing users to perform DC voltage checks with ease and confidence.In addition to the reliability and user-friendly features, {Company Name}'s multimeters are built to withstand the demands of various work environments. They are constructed with durable materials and are tested to ensure their resilience to extreme conditions. This makes them suitable for use in industrial settings, construction sites, and other challenging work environments where reliable electrical testing tools are essential.With a commitment to quality and innovation, {Company Name} continues to develop multimeters that meet the evolving needs of professionals in the electrical industry. The company's dedication to excellence has made it a trusted provider of reliable and accurate electrical testing instruments.In conclusion, the DC voltage check feature in {Company Name}'s multimeters provides professionals with a reliable and accurate tool for measuring and testing DC voltage in electrical circuits and components. With a focus on precision, durability, and user convenience, {Company Name} is committed to providing high-quality multimeters that meet the demanding requirements of various industries. Whether it is for troubleshooting electrical issues, inspecting equipment, or maintaining electrical systems, {Company Name}'s multimeters are the go-to choice for professionals who require precision and reliability in their electrical testing tools.

High-Quality PCB Stencil for Precise Circuit Board Assembly

Innovative Technology Company Introduces Advanced PCB Stencil for Precision ManufacturingLeading the way in the technology industry, a pioneering company has unveiled a cutting-edge PCB stencil that is set to revolutionize the manufacturing process for electronic devices. This state-of-the-art stencil, which incorporates the latest advancements in precision engineering, is poised to provide an unprecedented level of accuracy and reliability in the production of printed circuit boards (PCBs). With a focus on delivering superior quality and performance, the company is dedicated to pushing the boundaries of innovation and setting new industry standards.With an unwavering commitment to excellence, the company has invested heavily in research and development to create a PCB stencil that is unrivaled in its precision and efficiency. By harnessing the power of advanced technology, the company has successfully engineered a stencil that is capable of meeting the exacting demands of modern manufacturing processes. Through extensive testing and refinement, the company has achieved a level of precision that exceeds industry expectations, making their PCB stencil the ideal choice for high-tech manufacturing applications.The key to the success of the company's PCB stencil lies in its innovative design, which has been carefully engineered to deliver exceptional performance. Incorporating the latest advancements in materials and manufacturing techniques, the stencil boasts unparalleled durability and reliability, ensuring that it can withstand the rigors of high-volume production. Furthermore, the precision engineering of the stencil enables it to deliver consistently accurate results, making it an indispensable tool for manufacturers seeking to achieve the highest levels of quality and consistency in their products.In addition to its superior performance, the company's PCB stencil has been designed to streamline the manufacturing process, making it more efficient and cost-effective. By optimizing the transfer of solder paste onto PCBs, the stencil facilitates faster production cycles and reduces waste, ultimately leading to significant cost savings for manufacturers. Furthermore, the stencil's innovative features make it easy to use, allowing operators to achieve precise and uniform solder paste deposits with minimal effort.Through the introduction of their advanced PCB stencil, the company has once again demonstrated its position as a leader in the technology industry. With a proven track record of delivering innovative solutions that redefine industry standards, the company continues to drive progress and innovation in the field of electronic manufacturing. By setting new benchmarks for precision and reliability, the company's PCB stencil is poised to make a significant impact on the industry, providing manufacturers with a competitive edge in today's fast-paced market.As the company continues to push the boundaries of technological innovation, it remains dedicated to delivering cutting-edge solutions that empower manufacturers to achieve excellence in their products. With their advanced PCB stencil, the company is poised to play a pivotal role in shaping the future of electronic manufacturing, providing manufacturers with the tools they need to meet the demands of an increasingly sophisticated and competitive market. With a steadfast commitment to excellence, the company is set to lead the way in driving progress and innovation in the industry for years to come.

Quality PCBA Controller for Efficient Electronics Manufacturing

PCBA Controller - The Latest Innovation from Leading Electronics ManufacturerIn the fast-paced world of modern technology, the demand for advanced electronic solutions continues to soar. As a leading player in the electronics manufacturing industry, {Company name} has consistently demonstrated a commitment to innovation and excellence. The latest addition to their impressive portfolio of products is the PCBA Controller, a cutting-edge solution that is poised to revolutionize the industry.The PCBA Controller is a state-of-the-art electronic control system designed to meet the evolving needs of the electronics industry. Boasting advanced features and high-performance capabilities, this innovative product is expected to set new standards for precision and efficiency in electronic manufacturing processes.At the core of the PCBA Controller is a sophisticated control algorithm that leverages the latest advancements in artificial intelligence and machine learning. This enables the system to adapt to dynamic production environments, delivering unparalleled levels of accuracy and consistency in the assembly of printed circuit board assemblies (PCBAs).One of the key highlights of the PCBA Controller is its seamless integration with {Company name}'s proprietary software platform, which provides comprehensive control and monitoring capabilities. This allows for real-time performance analysis, predictive maintenance, and remote diagnostics, empowering manufacturers to optimize their production processes and maximize operational efficiency.In addition to its advanced technological features, the PCBA Controller is also designed with user-friendly interfaces and intuitive controls, making it accessible to operators of varying skill levels. This emphasis on usability reflects {Company name}'s dedication to creating solutions that prioritize ease of use and accessibility, ultimately enhancing the overall user experience.{Company name} is renowned for its unwavering commitment to quality, and the PCBA Controller is no exception. Rigorous testing and thorough quality assurance processes ensure that the product meets the highest standards of reliability and durability. With a robust build and resilient components, the PCBA Controller is engineered to withstand the demands of industrial settings, delivering consistent performance over extended periods of operation.The launch of the PCBA Controller represents a significant milestone for {Company name}, underscoring their dedication to pushing the boundaries of technological innovation. This latest offering reinforces their position as a pioneering force in the electronics manufacturing industry, further solidifying their reputation as a trusted partner for businesses seeking cutting-edge solutions.In line with their commitment to sustainable practices, {Company name} has also prioritized the environmental impact of the PCBA Controller. The system is designed with energy-efficient features and eco-friendly materials, minimizing its carbon footprint while upholding performance standards.The introduction of the PCBA Controller is expected to have far-reaching implications for the electronics manufacturing industry, offering a game-changing solution that promises to streamline production processes, improve product quality, and drive operational efficiency. By leveraging the power of advanced technology, {Company name} continues to empower businesses to achieve their production goals with unprecedented precision and reliability.As the global demand for electronic components and devices continues to grow, {Company name} remains at the forefront of innovation, delivering solutions that address the evolving needs of the industry. The PCBA Controller stands as a testament to their unwavering pursuit of excellence and their commitment to shaping the future of electronics manufacturing. With its cutting-edge capabilities and uncompromising quality, the PCBA Controller is set to make a lasting impact, cementing {Company name}'s position as an industry leader.

High-Precision Laser Cutter for PCB Stencils: Streamline Your Manufacturing Process

[Company Name] Unveils Cutting-Edge PCB Stencil Laser Cutter for Enhanced Precision and Efficiency[City, Date] – [Company Name], a leading provider of innovative electronic manufacturing solutions, has announced the release of its latest PCB stencil laser cutter. This new cutting-edge technology is poised to revolutionize the industry by offering unparalleled precision and efficiency in the production of printed circuit boards (PCBs).The PCB stencil laser cutter is designed to meet the increasing demand for high-quality PCB stencils in the electronics manufacturing sector. By utilizing advanced laser cutting technology, [Company Name] aims to provide its customers with a solution that streamlines the PCB production process and delivers superior results.“At [Company Name], we are committed to staying ahead of the curve and providing our customers with the most advanced and efficient manufacturing solutions. The release of our PCB stencil laser cutter is a testament to our dedication to innovation and our relentless pursuit of excellence,” said [Spokesperson Name], [Title] at [Company Name].The PCB stencil laser cutter boasts a number of key features that set it apart from traditional stencil cutting methods. Its high-precision laser cutting technology ensures that even the most intricate PCB designs can be accurately replicated onto the stencil with minimal margin for error. This level of precision is crucial in the production of modern, complex PCBs that require exacting specifications.Furthermore, the PCB stencil laser cutter is capable of producing stencils at a significantly faster rate than traditional cutting methods. This not only increases production efficiency but also allows [Company Name] to meet the growing demand for quick turnaround times without compromising on quality.In addition to its precision and speed, the PCB stencil laser cutter is also highly versatile. It can accommodate a wide range of materials, including stainless steel, brass, and nickel, allowing [Company Name] to offer a diverse selection of stencil options to its customers.From a customer perspective, the benefits of [Company Name]’s new PCB stencil laser cutter are numerous. By providing stencils that are precisely tailored to their specific PCB designs, customers can expect improved consistency and accuracy in their manufacturing processes. This, in turn, leads to enhanced product quality and reliability, ultimately benefiting end-users.“We believe that the introduction of our PCB stencil laser cutter will have a significant impact on the electronics manufacturing industry. The level of precision and efficiency it offers is unparalleled, and we are excited to see the positive impact it will have on our customers’ operations,” added [Spokesperson Name].As a company that prides itself on its commitment to excellence, [Company Name]’s investment in the latest PCB stencil laser cutting technology reaffirms its position as a leader in the electronic manufacturing industry. By continuously striving to raise the bar in terms of technological innovation, [Company Name] remains at the forefront of delivering solutions that meet the evolving needs of its customers.With the introduction of the PCB stencil laser cutter, [Company Name] has once again demonstrated its dedication to providing cutting-edge solutions that drive success for its customers. As technology continues to advance, [Company Name] is well-positioned to lead the way in shaping the future of electronic manufacturing.For more information about [Company Name] and its range of electronic manufacturing solutions, visit [company website].

Understanding the Function and Benefits of Radial Inductors

Radial Inductor, a leading provider of cutting-edge electronic components, is making waves in the industry with its latest innovation. This innovative product promises to revolutionize the way electronic devices are powered and is expected to have a significant impact on the market.The new radial inductor is designed to provide superior performance and efficiency, making it an ideal choice for a wide range of electronic applications. Its compact size and high power density make it perfect for use in everything from consumer electronics to industrial equipment.One of the key features of the radial inductor is its high energy storage capacity, which allows for more efficient energy transfer and reduced power losses. This means that electronic devices powered by the radial inductor will be able to operate more efficiently and for longer periods of time.In addition to its impressive performance capabilities, the radial inductor is also highly reliable, thanks to its robust design and high-quality materials. This makes it an excellent choice for use in applications where reliability is of the utmost importance."We are thrilled to introduce our latest radial inductor to the market," said [Company Name]'s CEO. "We believe that this innovative product has the potential to greatly improve the performance and efficiency of electronic devices across a wide range of industries. We are confident that this product will be well-received by our customers and will help us continue to lead the way in the electronic components industry."In line with the company's commitment to innovation and excellence, the new radial inductor is backed by [Company Name]'s extensive research and development efforts. The company's team of engineers and scientists have worked tirelessly to develop this groundbreaking product, ensuring that it meets the highest standards of quality and performance.The launch of the radial inductor comes at a time when the demand for high-performance electronic components is higher than ever. As electronic devices continue to become more advanced and sophisticated, there is an increasing need for components that can keep up with the growing demands of modern technology. The radial inductor is poised to meet this need head-on, offering a solution that is both powerful and efficient.The introduction of the radial inductor is sure to solidify [Company Name]'s position as a leader in the electronic components industry. With its strong commitment to innovation, quality, and customer satisfaction, the company is well-positioned to continue driving the industry forward and shaping the future of electronic technology."As we look to the future, we are excited about the possibilities that our new radial inductor presents," said [Company Name]'s CEO. "We are confident that it will make a significant impact on the market and help us maintain our position as a trusted provider of high-quality electronic components."The radial inductor is now available for purchase and is expected to quickly gain traction in the market. With its unparalleled performance, reliability, and efficiency, it is poised to become a go-to choice for designers and manufacturers looking to take their electronic devices to the next level.In conclusion, the introduction of the radial inductor represents a major milestone for [Company Name] and a significant advancement in the electronic components industry. With its exceptional performance capabilities and wide range of applications, this innovative product is set to make a lasting impact on the market and solidify [Company Name]'s reputation as a leading provider of cutting-edge electronic components.

A Guide to Hobbyist PCB Assembly: Everything You Need to Know

Hobbyist PCB Assembly: A Passion Turned into a BusinessIn recent years, the rise of do-it-yourself (DIY) electronics and the maker movement has led to an increased interest in hobbyist PCB assembly. As more and more people delve into the world of electronics design and manufacturing, the demand for high-quality PCB assembly services for hobbyists has also grown. [Company Name], a leading PCB assembly company, has recognized this growing trend and has taken the initiative to cater to the needs of hobbyists and DIY enthusiasts.The company has been in the PCB assembly industry for over a decade, specializing in providing top-notch assembly services for clients in various industries, including automotive, medical, aerospace, and consumer electronics. With their state-of-the-art facilities and experienced team of engineers, [Company Name] has gained a reputation for delivering high-quality PCB assembly solutions that meet the highest standards.Recently, [Company Name] has extended its services to cater to hobbyists and DIY enthusiasts who are looking for reliable and affordable PCB assembly solutions for their projects. By leveraging their expertise and resources, the company aims to support and empower individuals who are passionate about electronics design and manufacturing.One of the key advantages of choosing [Company Name] for hobbyist PCB assembly is their commitment to quality. The company employs rigorous quality control processes to ensure that every PCB assembly meets the highest standards of reliability and performance. This level of quality assurance is crucial for hobbyists who are often working on projects that require precision and reliability.Moreover, [Company Name] offers flexibility in their services, allowing hobbyists to customize their PCB assembly requirements according to their specific needs. Whether it's a small batch of prototype PCBs for a pet project or a larger production run for a DIY product, the company can accommodate varying order sizes while maintaining the same level of quality and attention to detail.In addition to their commitment to quality and flexibility, [Company Name] also prides itself on providing excellent customer service. The company's team of experts is dedicated to guiding hobbyists through the PCB assembly process, from design to production, ensuring that their projects are completed successfully and to their satisfaction.Furthermore, [Company Name] understands the importance of cost-effectiveness for hobbyists and DIY enthusiasts. As such, the company offers competitive pricing for their PCB assembly services, making it more accessible for individuals working on personal projects with budget constraints.To further support hobbyists and DIY enthusiasts, [Company Name] also provides educational resources and guidance on PCB design and assembly. Through blog posts, tutorials, and webinars, the company aims to share their knowledge and expertise with the community, helping hobbyists enhance their skills and understanding of PCB assembly.With their commitment to quality, flexibility, customer service, and affordability, [Company Name] is well-positioned to meet the growing demand for hobbyist PCB assembly services. By leveraging their experience in serving clients across various industries, the company is able to bring professional-grade PCB assembly solutions to the DIY community, empowering individuals to turn their electronic design ideas into reality.For hobbyists and DIY enthusiasts who are passionate about electronics and PCB assembly, [Company Name] is a reliable partner that provides the expertise and support needed to bring their projects to life. Whether it's a simple LED circuit or a complex microcontroller project, the company is dedicated to helping hobbyists achieve their goals and make their mark in the world of electronics design and manufacturing.

Efficient Surface Mount PCB Soldering Techniques for High-Quality Assembly

Surface mount PCB soldering is a critical process in the manufacturing of electronic devices. It involves the attachment of electronic components to a printed circuit board (PCB) using solder paste and a reflow soldering process. This process is vital for ensuring the reliability and functionality of the electronics and requires advanced machinery and expertise.Relying on technology and expertise, {company name} has established itself as a leader in the surface mount PCB soldering industry. With a commitment to precision and quality, the company has become a trusted partner for businesses across various industries, including automotive, aerospace, telecommunications, and consumer electronics.{Company name} specializes in providing comprehensive surface mount PCB soldering solutions, handling a wide range of PCB sizes and complexities. The company's state-of-the-art facilities are equipped with advanced machinery and technology, allowing for precise and efficient soldering processes.One of the key aspects of {company name}'s surface mount PCB soldering capability is its adherence to strict quality control measures. The company employs a team of highly skilled technicians who are trained to ensure that every soldering process meets the highest industry standards. Additionally, {company name} utilizes cutting-edge inspection equipment to verify the quality and reliability of the solder joints, guaranteeing that the finished PCBs meet the client's specifications and expectations.{Company name} also prides itself on its ability to accommodate custom requirements and tight production schedules. The company works closely with its clients to understand their specific needs and deliver tailored surface mount PCB soldering solutions that meet their unique requirements. This level of personalized service has earned {company name} a reputation for reliability and flexibility in the industry.In addition to its technical expertise, {company name} places a strong emphasis on environmental sustainability and social responsibility. The company has implemented green manufacturing practices and adheres to strict environmental regulations, ensuring that its operations have minimal impact on the environment. Furthermore, {company name} is committed to ethical business practices and upholds the highest standards of integrity and transparency in all its dealings.{Company name} is constantly seeking to innovate and improve its surface mount PCB soldering capabilities. The company invests in research and development to stay at the forefront of technological advancements in the industry. By staying ahead of the curve, {company name} can continue to provide its clients with the most cutting-edge and reliable surface mount PCB soldering solutions.As the demand for high-quality electronics continues to grow, {company name} remains dedicated to meeting the ever-evolving needs of its clients. The company's unwavering commitment to excellence and customer satisfaction has solidified its position as a trusted leader in the surface mount PCB soldering industry. Looking ahead, {company name} is poised to continue its growth and success by delivering innovative solutions and unparalleled service to its clients.