Comparing Rigid and Flexible PCB: Understanding the Differences

By:Admin

{Company name} has been at the forefront of PCB manufacturing for over two decades. With a strong emphasis on quality, innovation, and customer satisfaction, {company name} has established itself as a trusted supplier of rigid and flexible PCBs to a wide range of industries including telecommunications, automotive, aerospace, and consumer electronics.

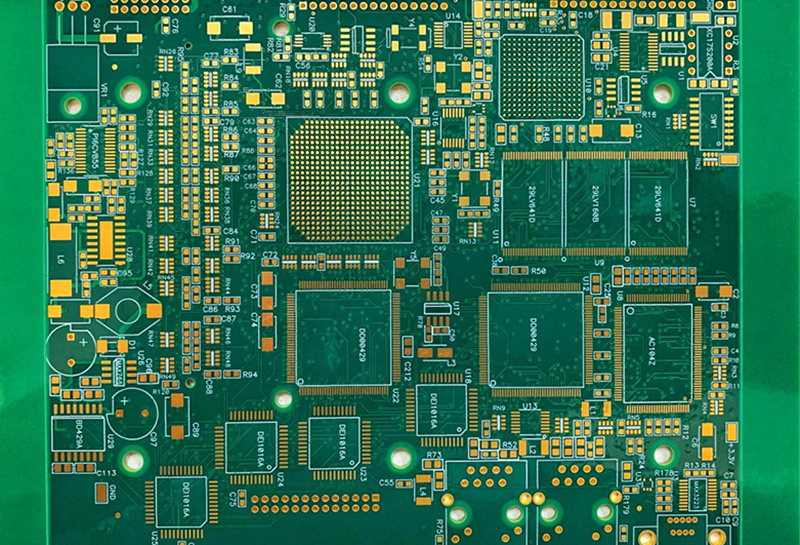

Rigid PCBs are the traditional and most common type of PCB used in electronic devices. These boards are made of solid substrate materials such as fiberglass, and they are capable of supporting heavy components. Rigid PCBs are ideal for applications where durability and stability are paramount, such as in automotive electronics and industrial control systems.

On the other hand, flexible PCBs are designed to be more versatile and adaptable to the shape and size requirements of the device they are used in. These boards are made of flexible substrate materials such as polyimide, which allows them to be bent, twisted, and folded without compromising their functionality. Flexible PCBs are widely used in portable electronic devices such as smartphones, tablets, and wearable technology.

{Company name} has a comprehensive range of capabilities in the production of both rigid and flexible PCBs. Its state-of-the-art manufacturing facilities are equipped with advanced machinery and technology to ensure the highest quality and precision in every PCB produced. The company's team of experienced engineers and technicians are well-versed in the latest industry standards and best practices, allowing them to deliver PCB solutions that meet the most stringent requirements of their customers.

In addition to its standard PCB offerings, {company name} also specializes in the design and production of custom PCBs tailored to the specific needs of its clients. Whether it's a complex multilayer rigid PCB for a telecommunications infrastructure project or a flexible PCB for a cutting-edge medical device, {company name} has the technical expertise and production capacity to deliver high-quality, custom PCB solutions.

One of the key factors that sets {company name} apart from its competitors is its unwavering commitment to quality and reliability. The company adheres to strict quality control processes at every stage of the production cycle, from raw material inspection to final product testing. This rigorous approach to quality has earned {company name} the trust and confidence of its customers, who rely on the company for PCB solutions that perform consistently and reliably in their applications.

Furthermore, {company name} is dedicated to environmental sustainability and ethical manufacturing practices. The company is certified to the highest industry standards for environmental management and occupational health and safety, demonstrating its commitment to minimizing its environmental footprint and ensuring the well-being of its employees.

Looking ahead, {company name} continues to invest in research and development to stay at the forefront of PCB technology. The company is actively exploring new materials, processes, and design techniques to push the boundaries of what is possible in PCB manufacturing. By embracing innovation and continuous improvement, {company name} aims to remain a leader in the PCB industry and a go-to partner for companies seeking reliable and high-quality PCB solutions.

In conclusion, {company name} is a reputable and reliable supplier of rigid and flexible PCBs for a wide range of industries. With its advanced manufacturing capabilities, commitment to quality, and dedication to innovation, {company name} is well-positioned to meet the evolving needs of the electronics industry and continue to serve as a trusted partner for its customers.

Company News & Blog

Why Military Forces Employ PCB Technology for Advanced Operations

This just in: The army has been making use of printed circuit boards (PCBs) in their latest equipment to enhance communication and technology capabilities on the battlefield. This cutting-edge technology provides soldiers with advanced communication and information systems, allowing for a more efficient and effective military presence in combat situations.The use of PCBs in military equipment is not a new concept. In fact, PCBs have been a critical component in military equipment for decades, providing a reliable and durable platform for electronic components to operate in harsh and demanding environments. These boards are essential in ensuring that electronic systems within military equipment can withstand the rigors of combat and operate with precision and accuracy.One company at the forefront of providing PCBs for military applications is {}. With years of experience in designing and manufacturing high-quality PCBs, {} has proven to be a trusted partner for various military organizations around the world. Their commitment to innovation and excellence has made them a go-to supplier for PCBs in the military sector.{} specializes in providing rugged and reliable PCBs that are specifically designed to meet the demands of military applications. These boards are built to withstand extreme temperatures, shock, and vibration, making them an ideal choice for military equipment operating in challenging environments. Whether it's for communication systems, surveillance equipment, or control panels, {} has the expertise to deliver PCB solutions that meet the stringent requirements of the military.The utilization of {}'s PCBs in military equipment has not only enhanced the performance of these systems but has also contributed to the overall effectiveness of military operations. By providing reliable and robust PCBs, {} plays a crucial role in ensuring that soldiers have access to the latest technology and communication systems, giving them a significant advantage on the battlefield.In addition to their expertise in designing and manufacturing PCBs for military applications, {} is also dedicated to upholding the highest standards of quality and conformity to strict military regulations and standards. The company's commitment to excellence and adherence to military specifications are paramount in ensuring that their products meet the rigorous demands of military operations.With the increasing reliance on advanced technology in modern warfare, the use of PCBs in military equipment is expected to continue growing. As military organizations seek to enhance their communication and technology capabilities, companies like {} will play a pivotal role in providing cutting-edge PCB solutions that meet the unique requirements of military applications.In conclusion, the utilization of PCBs in military equipment is a critical component in enhancing the communication and technology capabilities of military operations. With companies like {} at the forefront of providing high-quality and reliable PCB solutions, the military can be assured that their equipment will perform with precision and durability in the most demanding environments. As technology continues to evolve, the role of PCBs in military equipment will undoubtedly remain crucial in ensuring the effectiveness and success of military operations.

The Latest Advancements in Multilayer PCB Fabrication: What You Need to Know

In the world of advanced electronics and technology, the demand for multilayer PCB (Printed Circuit Board) fabrication has been growing rapidly. These PCBs are essential components in a wide range of devices, from smartphones and computers to medical equipment and automotive systems. As the need for smaller, more efficient, and high-performance electronic devices continues to rise, so does the demand for advanced PCB fabrication technology.One company that has been at the forefront of multilayer PCB fabrication is {}. With their state-of-the-art facilities and advanced manufacturing processes, they have been able to meet the growing demand for high-quality multilayer PCBs. The company has a long history of innovation and excellence in the field of electronic components and has become a trusted partner for many leading electronics manufacturers around the world.{} is committed to providing their customers with the highest quality multilayer PCBs, and they have invested heavily in their manufacturing facilities to achieve this goal. The company's production lines are equipped with advanced machinery and equipment to ensure precision and accuracy in the fabrication process. Their team of skilled engineers and technicians work tirelessly to maintain the highest standards of quality and reliability in every PCB they produce.One of the key advantages of multilayer PCBs is their ability to accommodate complex electronic circuits in a compact and efficient manner. This makes them an ideal choice for modern electronic devices that require high performance and reliability in a small form factor. With the capability to integrate multiple layers of conductive tracks and insulating layers, multilayer PCBs enable designers to create sophisticated electronic systems with greater flexibility and efficiency.The demand for multilayer PCB fabrication has been particularly strong in industries such as telecommunications, aerospace, automotive, and medical devices. These industries require high-performance electronic components that can withstand harsh operating conditions and operate reliably in critical applications. {} has been able to meet the stringent requirements of these industries by offering a wide range of multilayer PCBs that are designed to deliver superior performance and reliability.In addition to their commitment to quality and innovation, {} places a strong emphasis on environmental sustainability in their manufacturing processes. They have implemented stringent measures to minimize waste and reduce energy consumption in their facilities. The company also adheres to strict environmental regulations and standards to ensure that their operations have minimal impact on the environment.As the demand for advanced electronics continues to rise, {} is well-positioned to capitalize on the growing market for multilayer PCB fabrication. With their advanced manufacturing capabilities, commitment to quality and reliability, and focus on environmental sustainability, they have established themselves as a leading provider of multilayer PCBs in the global electronics industry.In conclusion, the demand for multilayer PCB fabrication continues to grow as electronic devices become increasingly advanced and sophisticated. With their advanced manufacturing facilities, strong commitment to quality, and focus on environmental sustainability, {} is well-equipped to meet the evolving needs of the electronics industry. Their dedication to innovation and excellence in PCB fabrication has made them a trusted partner for leading electronics manufacturers around the world, and they are well-positioned to continue driving the advancement of electronic technology for years to come.

What is a Black PCB Board and How is it Used?

Black PCB Board: The Latest Innovation by a Leading Electronics CompanyIn the world of electronics, innovation and quality are paramount. The rapidly evolving technology landscape demands cutting-edge solutions that not only meet current needs but also anticipate the future. One company that has continually demonstrated its commitment to excellence and innovation is [remove brand name]. Renowned for its high-quality electronic components and exceptional products, [brand name] has recently unveiled its latest innovation: the Black PCB Board.The Black PCB Board is a groundbreaking development in the field of electronics. As the heart and soul of any electronic device, the printed circuit board (PCB) plays a crucial role in ensuring the proper functioning of electronic components. What sets the Black PCB Board apart is its unique design and construction, offering superior performance and reliability.[Brand name] has a rich history of delivering state-of-the-art electronic solutions to its customers. With a focus on research and development, the company has consistently pushed the boundaries of innovation, leading to the creation of cutting-edge products that have set new industry standards. The introduction of the Black PCB Board is yet another testament to [brand name]'s unwavering commitment to excellence and pioneering technology.The Black PCB Board boasts a number of key features that set it apart from traditional PCBs. The board is designed to provide enhanced electrical performance, making it ideal for demanding applications where precision and reliability are essential. Its black color not only adds to its aesthetic appeal but also serves a practical purpose by reducing the potential for signal interference and crosstalk.In addition to its superior performance, the Black PCB Board is built to withstand the rigors of various operating environments. Its robust construction and durable materials ensure long-term reliability, making it a preferred choice for a wide range of electronic applications. Whether used in consumer electronics, automotive systems, industrial equipment, or aerospace technology, the Black PCB Board delivers uncompromising performance.Furthermore, [brand name] has incorporated advanced manufacturing techniques and rigorous quality control measures to ensure that every Black PCB Board meets the highest standards. The company's state-of-the-art facilities and experienced engineering team are dedicated to producing PCBs of the utmost quality, setting a new benchmark in the industry.The launch of the Black PCB Board underscores [brand name]'s continued dedication to innovation and customer satisfaction. By providing a superior product that meets the ever-evolving demands of the electronics industry, the company reinforces its position as a leader in the field. Customers can trust [brand name] to deliver cutting-edge solutions that empower their own products and technologies.In conclusion, the introduction of the Black PCB Board by [brand name] marks a significant milestone in the world of electronics. With its exceptional performance, durability, and reliability, this innovative PCB sets a new standard for electronic components. As [brand name] continues to push the boundaries of innovation, customers can expect to benefit from groundbreaking technologies that redefine the industry. The Black PCB Board is a testament to [brand name]'s unwavering commitment to excellence and its relentless pursuit of innovative solutions.

High Quality Rigid PCB for Electronic Applications

We are excited to announce that {} has recently developed a cutting-edge product, the Fr4 Rigid PCB, that is set to revolutionize the electronic manufacturing industry. This innovative new product is a testament to our commitment to providing our customers with the most advanced and reliable technology available on the market.The Fr4 Rigid PCB is a type of printed circuit board that is specially designed to provide a rigid and durable base for electronic components. Unlike traditional PCBs, which are made from less rigid materials, the Fr4 Rigid PCB offers increased stability and support, making it the ideal choice for a wide range of electronic applications.One of the key features of the Fr4 Rigid PCB is its high thermal conductivity, which allows for efficient heat dissipation and helps to prevent overheating of electronic components. This is particularly important in industries such as telecommunications, automotive, and aerospace, where electronic devices are often subjected to extreme temperatures and environmental conditions.In addition to its superior thermal conductivity, the Fr4 Rigid PCB also boasts excellent electrical insulation properties, making it an ideal choice for high-performance electronic devices. This ensures that the PCB can effectively protect sensitive electronic components from interference and damage, resulting in improved overall performance and reliability.Furthermore, the Fr4 Rigid PCB is highly resistant to chemical and environmental degradation, making it suitable for use in harsh operating environments. This makes it an excellent choice for applications that require long-term durability and reliability, such as industrial control systems and medical devices.At {}, we are proud to be at the forefront of technological innovation, and the development of the Fr4 Rigid PCB is a reflection of our ongoing commitment to pushing the boundaries of what is possible in the electronic manufacturing industry. Our dedicated team of engineers and researchers have worked tirelessly to develop this groundbreaking new product, and we are confident that it will set a new standard for quality and performance in the PCB market.With the introduction of the Fr4 Rigid PCB, we are excited to offer our customers a product that not only meets their current needs but also anticipates and exceeds their future requirements. Our goal is to continue to provide our customers with the most advanced and reliable electronic solutions available, and the Fr4 Rigid PCB is a testament to this commitment.In conclusion, the introduction of the Fr4 Rigid PCB marks a significant milestone for {}. This innovative new product represents a leap forward in electronic manufacturing technology and reaffirms our position as a leader in the industry. We are confident that the Fr4 Rigid PCB will offer our customers a level of performance and reliability that is unmatched in the market, and we are excited to see the positive impact it will have on a wide range of electronic applications.

A Beginner's Guide to SMD Components: Everything You Need to Know

The demand for basic Surface Mount Device (SMD) components has been on the rise in recent years. These components, such as resistors, capacitors, and diodes, play a crucial role in the manufacturing of a wide range of electronic products. As the digital revolution continues to expand, the need for these basic SMD components has only increased, leading to a surge in production and sales for companies in the industry.One such company that has been at the forefront of supplying basic SMD components is {}. Founded in {}, the company has established itself as a leading manufacturer and supplier of high-quality electronic components. With a strong emphasis on innovation and technological advancement, {} has continuously expanded its product line to meet the evolving needs of the electronics industry.The company's commitment to quality and reliability has made it a trusted partner for numerous businesses in the electronics manufacturing sector. With a strong focus on research and development, {} has been able to consistently deliver cutting-edge SMD components that meet the highest industry standards.One of the key factors that set {} apart from its competitors is its comprehensive range of basic SMD components. From surface mount resistors and capacitors to inductors and diodes, the company offers a diverse portfolio of products to cater to the diverse needs of its customers. With a strict emphasis on quality control and testing, {} ensures that its components are not only reliable but also perform optimally in various electronic applications.In addition to its product offerings, {} also provides exceptional customer service and support. The company's team of experienced professionals is dedicated to assisting customers with their specific requirements, whether it's custom component development or technical support for their existing products. This focus on customer satisfaction has helped {} build long-lasting relationships with its clients, further solidifying the company's position as a trusted partner in the industry.As the demand for basic SMD components continues to grow, {} has been proactive in expanding its production capabilities to meet the market needs. Investing in state-of-the-art manufacturing facilities and cutting-edge equipment, the company has been able to increase its production capacity while maintaining the highest quality standards. This has allowed {} to not only keep up with the growing demand but also stay ahead of the curve in terms of innovation and technological advancement.Looking ahead, {} remains committed to pushing the boundaries of electronic component manufacturing. The company continues to invest in research and development to create new and improved SMD components that meet the evolving needs of the industry. With a solid foundation built on quality, reliability, and customer satisfaction, {} is well-positioned to remain a leader in the basic SMD components market for years to come.In conclusion, the demand for basic SMD components is on the rise, and companies like {} are playing a crucial role in meeting this demand. With a strong focus on quality, innovation, and customer satisfaction, {} has established itself as a trusted partner for businesses in the electronics manufacturing sector. As the industry continues to evolve, {} remains dedicated to staying at the forefront of electronic component manufacturing, ensuring that its customers have access to the best SMD components for their applications.

Understanding Active and Passive Components: The Basics

[Company Name], a leading provider of electronic components, has announced the release of a new range of active and passive components for the electronics industry. These components are designed to meet the growing demand for high-performance and reliable electronic products in various applications.The company is known for its commitment to innovation and quality in the electronic components industry. With over [number] years of experience, [Company Name] has established itself as a trusted supplier of a wide range of electronic components for manufacturers worldwide.The new range of active components includes a variety of highly efficient and reliable products, such as amplifiers, oscillators, and integrated circuits. These components are designed to enhance the performance and functionality of electronic devices, making them suitable for a wide range of applications, including telecommunications, industrial control, and automotive electronics.In addition to the active components, [Company Name] has also introduced a new series of passive components, including resistors, capacitors, and inductors. These components are essential for creating stable and reliable electronic circuits, and [Company Name] is committed to delivering high-quality passive components that are suitable for use in a wide range of electronic products.The new range of active and passive components from [Company Name] is designed to meet the increasing demand for electronic components that offer high performance, reliability, and durability. The company’s dedication to quality and innovation is evident in the design and manufacturing of these components, which are engineered to deliver exceptional performance in demanding applications.[Company Name] is known for its expertise in electronic component manufacturing and its ability to deliver high-quality products that meet the needs of the electronics industry. The company’s state-of-the-art manufacturing facilities and stringent quality control processes ensure that its products meet the highest standards of performance, reliability, and durability.With the release of the new range of active and passive components, [Company Name] is well-positioned to meet the evolving needs of the electronics industry. The company’s commitment to innovation and quality ensures that its products are suitable for a wide range of applications, from consumer electronics to industrial automation.“Our new range of active and passive components reflects our commitment to delivering high-performance and reliable electronic components to our customers,” said [Company Name]’s CEO. “We are dedicated to meeting the increasing demand for electronic components that offer exceptional performance and durability, and our new range of components is a testament to our ongoing commitment to innovation and quality.”The new range of active and passive components from [Company Name] is now available for purchase, and the company is confident that these components will meet the needs of electronics manufacturers worldwide. With its extensive experience and expertise in electronic component manufacturing, [Company Name] is well-equipped to deliver high-quality components that meet the highest standards of performance and reliability.

High-Quality Dvr Pcb Board for Improved Recording and Playback Experience

DVR PCB Board Paves the Way for Cutting-Edge Surveillance TechnologyIn today's rapidly evolving world, the need for reliable and advanced surveillance technology has never been greater. As the demand for surveillance systems continues to grow, one company is at the forefront of cutting-edge technology, providing innovative solutions that are revolutionizing the industry. With a commitment to excellence and a focus on delivering high-quality products, {Company} has established itself as a leader in the development and manufacturing of DVR PCB boards. These boards are an essential component of surveillance systems, playing a crucial role in capturing, processing, and storing video data.One of the key features that sets {Company} apart from its competitors is its dedication to research and development. The company invests heavily in the latest technologies, ensuring that its DVR PCB boards are equipped with the most advanced features and capabilities. This commitment to innovation has allowed {Company} to stay ahead of the curve and deliver cutting-edge solutions that meet the evolving needs of the surveillance industry.Another factor that sets {Company} apart is its focus on quality and reliability. The company understands that surveillance systems are often relied upon in critical situations, and as such, the performance of the DVR PCB boards is of utmost importance. {Company} takes great pride in the rigorous testing and quality control processes that all of its products undergo, ensuring that they meet the highest standards of performance and reliability.Furthermore, {Company} is committed to providing customized solutions to its customers. The company works closely with clients to understand their specific requirements and develop tailored solutions that meet their needs. Whether it's a small-scale residential surveillance system or a large-scale commercial installation, {Company} has the expertise and flexibility to deliver the right solution for every application.The success of {Company} can also be attributed to its strong focus on customer service and support. The company values its relationships with customers and strives to provide exceptional support throughout the entire product lifecycle. From initial consultation and design to after-sales support, {Company} is dedicated to ensuring that its customers have a positive and seamless experience.Looking to the future, {Company} remains committed to pushing the boundaries of surveillance technology and setting new industry standards. The company continues to invest in research and development, exploring emerging technologies and trends to ensure that its products remain at the forefront of innovation.In conclusion, {Company} has solidified its position as a leading provider of DVR PCB boards, offering cutting-edge solutions that are driving the evolution of surveillance technology. With a focus on innovation, quality, and customer satisfaction, {Company} is well-positioned to continue shaping the future of the surveillance industry.

Ultimate Guide to Debugging Gradle Tests

Gradle, a renowned software company in the field of software development, has recently announced a new feature in their latest software release — Gradle Test Debug. This new tool aims to revolutionize the way developers test and debug their code, making the process more efficient and productive.Gradle Test Debug offers a comprehensive suite of testing and debugging tools to help developers identify and fix issues in their code. With the ability to run tests and debug the code directly from the Gradle build, developers can now pinpoint and address any issues in their code easily and effectively.One of the key features of Gradle Test Debug is its advanced debugging capabilities. Developers can set breakpoints, inspect variables, and step through their code to identify and fix any issues. This allows for a more thorough and detailed analysis of the code, leading to better and more reliable software.In addition to debugging, Gradle Test Debug also offers a range of testing tools to ensure the quality and reliability of the code. Developers can run unit tests, integration tests, and even performance tests directly from the Gradle build, making it easier to identify and address any issues in the code.Furthermore, Gradle Test Debug integrates seamlessly with the existing Gradle build system, making it easy for developers to incorporate it into their workflow. With a simple and intuitive interface, developers can quickly get up to speed with Gradle Test Debug and start using it to improve the quality of their code."We are excited to introduce Gradle Test Debug to the developer community," said the CEO of Gradle. "We believe that this new feature will greatly enhance the testing and debugging process for developers, making it easier and more efficient to identify and fix issues in their code."The introduction of Gradle Test Debug is a testament to Gradle's commitment to providing innovative and cutting-edge solutions for software development. With a strong focus on making the development process more efficient and productive, Gradle continues to push the boundaries of what is possible in the world of software development.As a leading provider of software development tools, Gradle has a proven track record of delivering high-quality and reliable solutions to developers around the world. With the introduction of Gradle Test Debug, the company is once again demonstrating its ability to innovate and provide valuable tools for developers.In conclusion, Gradle Test Debug is set to revolutionize the way developers test and debug their code. With its advanced debugging capabilities and comprehensive testing tools, developers can now identify and address issues in their code more efficiently and effectively. This latest release further solidifies Gradle's position as a leader in the field of software development, and demonstrates their ongoing commitment to providing innovative and valuable solutions for developers.

How to Debug a Single Test: A Comprehensive Guide

Jest Debug Single Test: A Step Towards Improved Software TestingIn the fast-paced world of software development, ensuring the quality and reliability of code is of utmost importance. This is where testing comes into the picture, and tools like Jest play a crucial role in this process. However, it is not uncommon for developers to encounter issues while testing their code, and debugging a single test can be a challenging task. Fortunately, the latest update to Jest brings a solution to this common problem, making the testing process more efficient and seamless.With the new feature, developers can now easily debug a single test in Jest, allowing them to pinpoint and resolve issues with greater ease and speed. The ability to focus on a specific test without having to run the entire test suite not only saves time but also streamlines the debugging process, leading to more efficient and effective software testing.This update is a significant step forward for developers who rely on Jest for their testing needs. The company behind Jest, {} is committed to continually enhancing the capabilities of their tools to meet the evolving demands of the software development industry. By addressing the need for a more robust debugging process, {} is demonstrating its dedication to empowering developers with the tools they need to produce high-quality code.{} has a strong track record in the software development community, with a suite of tools and resources that are widely used and respected. Their commitment to innovation and continuous improvement is a driving force behind the success of their products, and the latest update to Jest is a testament to this dedication.In addition to the new debugging feature, Jest offers a range of capabilities that make it a preferred choice for many developers. Its intuitive and easy-to-use interface, along with comprehensive documentation and a supportive community, makes Jest a valuable asset for testing and ensuring the reliability of code.Furthermore, {} offers extensive support and resources for developers using Jest, including tutorials, forums, and online training, ensuring that users can make the most of the tool's capabilities. This commitment to empowering developers and providing them with the resources they need sets {} apart as a leader in the software development community.The introduction of the ability to debug a single test in Jest marks a significant advancement in the field of software testing. By streamlining the debugging process and making it more efficient, {} is empowering developers to produce high-quality code with greater ease and confidence. With the demand for reliable and robust software continuing to grow, tools like Jest play a crucial role in ensuring that the products and applications we rely on every day are dependable and efficient.In conclusion, the latest update to Jest, which allows developers to debug a single test, is a significant development that will benefit the software development community. As part of {}, Jest remains at the forefront of innovation and is committed to providing developers with the tools they need to succeed. With its user-friendly interface, comprehensive support, and now improved debugging capabilities, Jest is a valuable asset for any developer looking to ensure the quality and reliability of their code. As the demand for high-quality software continues to rise, tools like Jest will play a vital role in meeting these expectations and driving the industry forward.

Optimize Your Production Line with Automated PCB Testing

Automated PCB Testing Revolutionizes Quality Control at {}In the era of advanced technology and fast-paced production processes, the need for efficient quality control has become more crucial than ever. With the increasing complexity of electronic components, the demand for reliable and accurate testing methods has surged. One company that has truly embraced this challenge is {}.Based in the heart of the electronic manufacturing hub, {} has been a key player in providing cutting-edge solutions for the printed circuit board (PCB) industry. With a strong commitment to innovation and precision, the company has recently introduced an automated PCB testing system that is set to revolutionize the quality control process.The automated PCB testing system developed by {} represents a significant advancement in the industry. By combining state-of-the-art technology with a deep understanding of the challenges faced by electronic manufacturers, {} has created a solution that promises to streamline the testing process and deliver superior results.Traditionally, PCB testing has been a time-consuming and labor-intensive task, often prone to errors and inconsistencies. Manual testing methods are not only slow and inefficient, but also leave room for human error, leading to potential defects slipping through the cracks. {}'s automated testing system addresses these issues by offering a seamless and reliable testing process that ensures the highest level of quality control.One of the key features of {}'s automated PCB testing system is its ability to detect defects with unmatched precision. Equipped with advanced sensors and intelligent algorithms, the system is capable of identifying even the smallest imperfections in PCBs, ensuring that only the highest quality products make it to the market. This level of accuracy not only enhances the overall quality control process but also helps to minimize the risk of product recalls and costly rework.Moreover, the automated testing system significantly reduces the time and resources required for testing. By automating the process, {} has managed to greatly increase efficiency and throughput, enabling manufacturers to meet tight production deadlines without compromising on quality. This is particularly crucial in today's fast-paced manufacturing environment, where time-to-market is a critical factor in staying competitive.In addition to its technical capabilities, {}'s automated PCB testing system is designed with user-friendliness in mind. The intuitive interface and easy-to-use controls make it accessible to operators of all levels of expertise, eliminating the need for extensive training and reducing the likelihood of operator error. This ensures that the system can be seamlessly integrated into existing production lines without causing disruptions or delays.Furthermore, {} provides comprehensive technical support and training to its clients, ensuring that they can maximize the benefits of the automated testing system. With a team of experienced engineers and technical experts, the company is committed to assisting its customers in optimizing their testing processes and achieving the best possible outcomes.The introduction of {}'s automated PCB testing system marks a significant milestone in the evolution of quality control in the electronic manufacturing industry. By leveraging the power of automation and advanced technology, {} has set a new standard for PCB testing, offering a solution that is not only more accurate and efficient but also more accessible and user-friendly.As the demand for high-quality electronic components continues to grow, the importance of reliable and efficient testing methods cannot be overstated. With its automated PCB testing system, {} has positioned itself as a leader in providing innovative solutions that address the key challenges faced by manufacturers, ultimately contributing to the advancement of the electronics industry as a whole.