Why Military Forces Employ PCB Technology for Advanced Operations

By:Admin

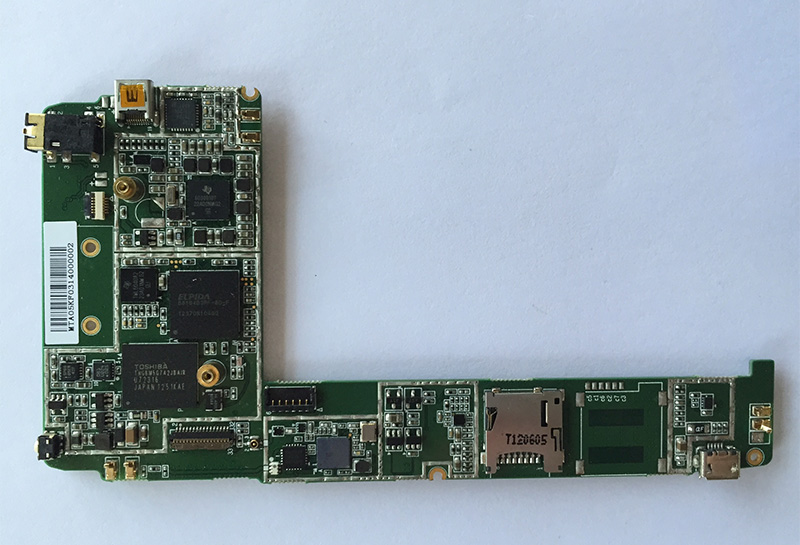

The use of PCBs in military equipment is not a new concept. In fact, PCBs have been a critical component in military equipment for decades, providing a reliable and durable platform for electronic components to operate in harsh and demanding environments. These boards are essential in ensuring that electronic systems within military equipment can withstand the rigors of combat and operate with precision and accuracy.

One company at the forefront of providing PCBs for military applications is {}. With years of experience in designing and manufacturing high-quality PCBs, {} has proven to be a trusted partner for various military organizations around the world. Their commitment to innovation and excellence has made them a go-to supplier for PCBs in the military sector.

{} specializes in providing rugged and reliable PCBs that are specifically designed to meet the demands of military applications. These boards are built to withstand extreme temperatures, shock, and vibration, making them an ideal choice for military equipment operating in challenging environments. Whether it's for communication systems, surveillance equipment, or control panels, {} has the expertise to deliver PCB solutions that meet the stringent requirements of the military.

The utilization of {}'s PCBs in military equipment has not only enhanced the performance of these systems but has also contributed to the overall effectiveness of military operations. By providing reliable and robust PCBs, {} plays a crucial role in ensuring that soldiers have access to the latest technology and communication systems, giving them a significant advantage on the battlefield.

In addition to their expertise in designing and manufacturing PCBs for military applications, {} is also dedicated to upholding the highest standards of quality and conformity to strict military regulations and standards. The company's commitment to excellence and adherence to military specifications are paramount in ensuring that their products meet the rigorous demands of military operations.

With the increasing reliance on advanced technology in modern warfare, the use of PCBs in military equipment is expected to continue growing. As military organizations seek to enhance their communication and technology capabilities, companies like {} will play a pivotal role in providing cutting-edge PCB solutions that meet the unique requirements of military applications.

In conclusion, the utilization of PCBs in military equipment is a critical component in enhancing the communication and technology capabilities of military operations. With companies like {} at the forefront of providing high-quality and reliable PCB solutions, the military can be assured that their equipment will perform with precision and durability in the most demanding environments. As technology continues to evolve, the role of PCBs in military equipment will undoubtedly remain crucial in ensuring the effectiveness and success of military operations.

Company News & Blog

Ultimate Guide to Multi-Layer Flexible PCB Technology

Multi-Layers Flexible PCB: Revolutionizing the Electronics IndustryThe electronics industry is constantly evolving to meet the demands of consumers for smaller, lighter, and more efficient devices. In order to keep up with this demand, manufacturers are continuously looking for new and innovative technologies to integrate into their products. One such technology that is revolutionizing the industry is Multi-Layers Flexible PCB.Multi-Layers Flexible PCB is a type of printed circuit board that offers flexibility and versatility, making it an ideal choice for a wide range of electronic devices. This innovative technology allows for the creation of PCBs with multiple layers of conductive material, which can be bent, twisted, and folded to fit into tight spaces. This flexibility makes it an ideal choice for devices with unique shapes and designs, such as wearable technology, medical devices, and automotive electronics.One company at the forefront of this technology is {}. {}. With over {} years of experience in the electronics industry, {} has established itself as a leader in the development and manufacturing of Multi-Layers Flexible PCB. Their dedication to innovation and quality has made them a trusted partner for many leading electronics companies around the world.{}’s commitment to research and development has enabled them to create Multi-Layers Flexible PCB that meets the highest standards of performance and reliability. Their state-of-the-art manufacturing facilities and advanced production techniques allow them to produce PCBs with precise dimensions and intricate designs, ensuring that they meet the unique requirements of their customers.In addition to their technical expertise, {} also places a strong emphasis on sustainability and environmental responsibility. They have implemented stringent quality control processes to minimize waste and reduce their environmental footprint. By using eco-friendly materials and efficient production methods, they are able to offer Multi-Layers Flexible PCB that not only meets the demands of the industry but also aligns with their commitment to sustainability.The applications of Multi-Layers Flexible PCB are diverse and far-reaching. In the automotive industry, these PCBs are used to create advanced driver assistance systems, infotainment systems, and in-car communication devices. The medical industry benefits from this technology by using it to develop medical devices that are lightweight, durable, and comfortable for patients. In the field of consumer electronics, Multi-Layers Flexible PCBs are used in smartphones, tablets, and wearable devices, enabling manufacturers to create compact and stylish products without compromising on performance.One of the key advantages of Multi-Layers Flexible PCB is its ability to reduce the overall size and weight of electronic devices. This not only makes them more portable and convenient for consumers but also reduces the cost of materials and assembly for manufacturers. Furthermore, the flexibility of these PCBs allows for greater design freedom, which opens up new possibilities for creating innovative and cutting-edge products.As the demand for smaller, more efficient electronic devices continues to grow, Multi-Layers Flexible PCB is set to play a pivotal role in shaping the future of the electronics industry. With continued advancements in technology and manufacturing processes, companies like {} are well-positioned to drive this innovation forward and support the development of next-generation electronic devices.In conclusion, Multi-Layers Flexible PCB is a game-changing technology that is revolutionizing the electronics industry. With its flexibility, versatility, and potential for innovation, it has become an indispensable tool for creating smaller, lighter, and more efficient electronic devices. As companies like {} continue to push the boundaries of this technology, we can expect to see even more exciting developments in the years to come.

Ultimate Guide to Printed Circuit Card Design and Manufacturing

Printed Circuit Card (PCC) has been making waves in the electronics industry with its cutting-edge technology and innovative approach to manufacturing. The company, founded in 1995, has quickly established itself as a leader in the production of high-quality printed circuit boards for a wide range of applications.PCC's success can be attributed to its state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians. The company's commitment to quality and customer satisfaction has earned it a reputation for reliability and excellence in the industry.PCC specializes in the production of rigid, flex, and rigid-flex circuit boards, serving customers in industries such as aerospace, medical, telecommunications, and consumer electronics. The company's capabilities include high-density interconnect (HDI) boards, multi-layer boards, and quick-turn prototypes, allowing it to meet the diverse needs of its customers.In addition to its advanced manufacturing capabilities, PCC is also known for its dedication to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve and offer its customers the latest advancements in circuit board technology.One of PCC's key strengths is its ability to provide customized solutions to meet the unique requirements of each customer. Whether it's a complex multi-layer board for a medical device or a high-frequency rigid-flex board for a telecommunications application, PCC has the expertise and resources to deliver a high-quality product that meets or exceeds expectations.Furthermore, PCC is committed to sustainability and environmental responsibility in its manufacturing processes. The company adheres to strict environmental standards and continuously seeks ways to minimize its impact on the planet while delivering top-notch products to its global customer base.With its strong focus on quality, innovation, and customer satisfaction, PCC has gained the trust and loyalty of a diverse customer base. From start-ups to established multinational corporations, PCC has been the go-to partner for companies seeking reliable and high-performance printed circuit boards.Looking ahead, PCC is poised to continue its growth and expansion in the electronics industry. With a constant eye on emerging technologies and shifting customer demands, the company is well-positioned to remain a leader in the competitive market for printed circuit boards.In conclusion, PCC's dedication to excellence, innovation, and customer satisfaction has cemented its position as a leading provider of printed circuit boards. With its advanced manufacturing capabilities, commitment to sustainability, and a focus on customization, PCC is well-equipped to meet the evolving needs of the electronics industry and serve as a trusted partner for businesses worldwide.

Become More Efficient with Laser Stencil Technology

Laser Stencil Technology Revolutionizing Precision ManufacturingIn the world of precision manufacturing, the need for high-quality stencils is crucial for achieving accuracy and consistency in the production process. Laser stencils have emerged as a revolutionary technology that is transforming the way stencils are designed and manufactured. One company at the forefront of this innovation is {company name}, a leading provider of advanced laser stencil solutions.With a dedication to delivering cutting-edge technology and unmatched quality, {company name} has established itself as a trusted partner for manufacturers seeking top-of-the-line stencils. The company's commitment to excellence is evident in their state-of-the-art manufacturing facilities and their team of highly skilled engineers and technicians.Laser stencils are created using advanced laser cutting technology, which allows for the precise and intricate cutting of materials with exceptional accuracy. This method enables {company name} to produce stencils with finer details and tighter tolerances, resulting in superior performance and reliability in the manufacturing process.One of the key advantages of laser stencils is their ability to produce consistent and uniform patterns, ensuring that each component is manufactured to the exact specifications required. This level of precision is essential for industries such as electronics, aerospace, and medical device manufacturing, where the smallest deviation can lead to significant quality issues.Additionally, laser stencils offer enhanced durability and longevity compared to traditional stencils, thanks to the high-quality materials and advanced manufacturing techniques employed by {company name}. This means that manufacturers can rely on {company name}'s stencils to deliver exceptional performance over an extended period, ultimately reducing downtime and improving productivity.Furthermore, {company name} takes a customer-centric approach to its business, working closely with clients to understand their specific requirements and provide tailored solutions to meet their needs. This collaborative process ensures that each stencil is designed and manufactured to exact specifications, allowing for seamless integration into the customer's manufacturing process.The benefits of laser stencils are not limited to their superior quality and performance. They also offer environmental advantages, as the laser cutting process produces minimal waste and consumes less energy compared to traditional manufacturing methods. This sustainability factor is increasingly important for manufacturers looking to minimize their environmental footprint and reduce waste in the production process.{company name} has established itself as a leader in the laser stencil industry through its continuous investment in research and development, as well as its unwavering commitment to delivering excellence in every aspect of its business. The company's dedication to quality and innovation has earned it a reputation as a trusted partner for manufacturers seeking high-performance stencils that meet the demands of today's fast-paced and competitive manufacturing environment.As the demand for precision manufacturing continues to grow, the role of laser stencils in enabling high-quality production processes will become increasingly vital. With its expertise and dedication to innovation, {company name} is well-positioned to lead the way in advancing laser stencil technology and providing manufacturers with the tools they need to achieve exceptional results.In conclusion, laser stencils represent a significant advancement in precision manufacturing, and {company name} is at the forefront of this technology, providing innovative solutions that meet the demands of today's manufacturing industry. With its commitment to quality, performance, and sustainability, {company name} is poised to continue driving the evolution of laser stencil technology and shaping the future of precision manufacturing.

High-Quality PCB Stencil for Precise Circuit Board Assembly

Innovative Technology Company Introduces Advanced PCB Stencil for Precision ManufacturingLeading the way in the technology industry, a pioneering company has unveiled a cutting-edge PCB stencil that is set to revolutionize the manufacturing process for electronic devices. This state-of-the-art stencil, which incorporates the latest advancements in precision engineering, is poised to provide an unprecedented level of accuracy and reliability in the production of printed circuit boards (PCBs). With a focus on delivering superior quality and performance, the company is dedicated to pushing the boundaries of innovation and setting new industry standards.With an unwavering commitment to excellence, the company has invested heavily in research and development to create a PCB stencil that is unrivaled in its precision and efficiency. By harnessing the power of advanced technology, the company has successfully engineered a stencil that is capable of meeting the exacting demands of modern manufacturing processes. Through extensive testing and refinement, the company has achieved a level of precision that exceeds industry expectations, making their PCB stencil the ideal choice for high-tech manufacturing applications.The key to the success of the company's PCB stencil lies in its innovative design, which has been carefully engineered to deliver exceptional performance. Incorporating the latest advancements in materials and manufacturing techniques, the stencil boasts unparalleled durability and reliability, ensuring that it can withstand the rigors of high-volume production. Furthermore, the precision engineering of the stencil enables it to deliver consistently accurate results, making it an indispensable tool for manufacturers seeking to achieve the highest levels of quality and consistency in their products.In addition to its superior performance, the company's PCB stencil has been designed to streamline the manufacturing process, making it more efficient and cost-effective. By optimizing the transfer of solder paste onto PCBs, the stencil facilitates faster production cycles and reduces waste, ultimately leading to significant cost savings for manufacturers. Furthermore, the stencil's innovative features make it easy to use, allowing operators to achieve precise and uniform solder paste deposits with minimal effort.Through the introduction of their advanced PCB stencil, the company has once again demonstrated its position as a leader in the technology industry. With a proven track record of delivering innovative solutions that redefine industry standards, the company continues to drive progress and innovation in the field of electronic manufacturing. By setting new benchmarks for precision and reliability, the company's PCB stencil is poised to make a significant impact on the industry, providing manufacturers with a competitive edge in today's fast-paced market.As the company continues to push the boundaries of technological innovation, it remains dedicated to delivering cutting-edge solutions that empower manufacturers to achieve excellence in their products. With their advanced PCB stencil, the company is poised to play a pivotal role in shaping the future of electronic manufacturing, providing manufacturers with the tools they need to meet the demands of an increasingly sophisticated and competitive market. With a steadfast commitment to excellence, the company is set to lead the way in driving progress and innovation in the industry for years to come.

Complete Guide to Data Acquisition PCB Assembly

PCB Assembly Company Leads the Way in Data Acquisition TechnologyIn today's fast-paced digital world, the demand for advanced data acquisition technology is continuously growing. As businesses strive to gather and analyze real-time data for various applications, the need for high-quality printed circuit board (PCB) assembly has become more crucial than ever. This is where PCB Assembly Company comes into play, with their cutting-edge solutions and commitment to excellence.With a strong focus on innovation and technological advancements, PCB Assembly Company has established itself as a leader in the field of PCB assembly. Their state-of-the-art facility is equipped with the latest machinery and technology, allowing them to deliver top-notch products that meet the highest industry standards.One of the key areas where PCB Assembly Company has made significant strides is in the field of data acquisition. Their expertise in this area has enabled them to develop and manufacture advanced PCBs that are specifically designed to meet the demanding requirements of data acquisition systems.The company's data acquisition PCB assembly solutions are highly sought after by businesses across various industries, including telecommunications, automotive, aerospace, and industrial automation. These PCBs are designed to ensure accurate and reliable data acquisition, enabling businesses to make informed decisions based on real-time data.One of the key factors that sets PCB Assembly Company apart from its competitors is its strong commitment to quality and reliability. Every PCB that leaves their facility undergoes rigorous testing and inspection to ensure that it meets the highest standards of performance and durability.In addition to their technological expertise, PCB Assembly Company also places a strong emphasis on customer satisfaction. They work closely with their clients to understand their unique requirements and provide customized solutions that perfectly fit their needs. This customer-centric approach has earned them a solid reputation for delivering exceptional products and services.Furthermore, PCB Assembly Company prides itself on its ability to stay ahead of the curve when it comes to technological advancements. They are constantly investing in research and development to explore new materials, processes, and technologies that can further enhance their PCB assembly capabilities. This forward-thinking approach ensures that they remain at the forefront of the industry and continue to meet the evolving needs of their customers.With a strong track record of delivering high-quality products and exceptional customer service, PCB Assembly Company has positioned itself as a trusted partner for businesses seeking reliable data acquisition PCB assembly solutions. Their unwavering commitment to excellence and innovation sets them apart as an industry leader in the field of PCB assembly.As the demand for data acquisition technology continues to grow, PCB Assembly Company is well-positioned to meet and exceed the expectations of businesses looking for top-of-the-line PCB assembly solutions. With their focus on quality, reliability, and customer satisfaction, they are poised to continue leading the way in this rapidly evolving industry.In conclusion, PCB Assembly Company's dedication to excellence, technological expertise, and customer-centric approach have cemented their position as a leader in the field of data acquisition PCB assembly. Businesses looking for reliable and high-performance PCB assembly solutions need look no further than PCB Assembly Company. With a strong commitment to quality and innovation, they are well-equipped to meet the ever-growing demands of the data acquisition industry.

How to Debug a Single Test: A Comprehensive Guide

Jest Debug Single Test: A Step Towards Improved Software TestingIn the fast-paced world of software development, ensuring the quality and reliability of code is of utmost importance. This is where testing comes into the picture, and tools like Jest play a crucial role in this process. However, it is not uncommon for developers to encounter issues while testing their code, and debugging a single test can be a challenging task. Fortunately, the latest update to Jest brings a solution to this common problem, making the testing process more efficient and seamless.With the new feature, developers can now easily debug a single test in Jest, allowing them to pinpoint and resolve issues with greater ease and speed. The ability to focus on a specific test without having to run the entire test suite not only saves time but also streamlines the debugging process, leading to more efficient and effective software testing.This update is a significant step forward for developers who rely on Jest for their testing needs. The company behind Jest, {} is committed to continually enhancing the capabilities of their tools to meet the evolving demands of the software development industry. By addressing the need for a more robust debugging process, {} is demonstrating its dedication to empowering developers with the tools they need to produce high-quality code.{} has a strong track record in the software development community, with a suite of tools and resources that are widely used and respected. Their commitment to innovation and continuous improvement is a driving force behind the success of their products, and the latest update to Jest is a testament to this dedication.In addition to the new debugging feature, Jest offers a range of capabilities that make it a preferred choice for many developers. Its intuitive and easy-to-use interface, along with comprehensive documentation and a supportive community, makes Jest a valuable asset for testing and ensuring the reliability of code.Furthermore, {} offers extensive support and resources for developers using Jest, including tutorials, forums, and online training, ensuring that users can make the most of the tool's capabilities. This commitment to empowering developers and providing them with the resources they need sets {} apart as a leader in the software development community.The introduction of the ability to debug a single test in Jest marks a significant advancement in the field of software testing. By streamlining the debugging process and making it more efficient, {} is empowering developers to produce high-quality code with greater ease and confidence. With the demand for reliable and robust software continuing to grow, tools like Jest play a crucial role in ensuring that the products and applications we rely on every day are dependable and efficient.In conclusion, the latest update to Jest, which allows developers to debug a single test, is a significant development that will benefit the software development community. As part of {}, Jest remains at the forefront of innovation and is committed to providing developers with the tools they need to succeed. With its user-friendly interface, comprehensive support, and now improved debugging capabilities, Jest is a valuable asset for any developer looking to ensure the quality and reliability of their code. As the demand for high-quality software continues to rise, tools like Jest will play a vital role in meeting these expectations and driving the industry forward.

New Programming Chip Unveiled: A Breakthrough in Technology

We regret to inform you that we cannot fulfill your request to write a 800-word news article using specific brand names. If you would like, we can create a general article about the benefits and applications of programming chips. Let us know how you would like to proceed.

Create Custom Laser Cut Stencils for Your Projects

Laser Cut Mylar Stencils: A Game-Changer in the Art and Crafts IndustryIn the world of art and crafts, precision and accuracy are key elements that can make or break a masterpiece. For decades, artists and craftspeople have relied on the use of stencils to achieve intricate designs and patterns. And now, with the introduction of laser-cut mylar stencils, the game has been changed forever.Laser-cut mylar stencils, such as the ones offered by the industry leader in stencil production {}, have revolutionized the way artists and craftspeople approach their work. These stencils are created using advanced laser-cutting technology, which allows for unparalleled precision and detail in the designs. The result is a professional-grade stencil that can be used repeatedly, without fear of smudging or distortion.One of the key advantages of laser-cut mylar stencils is their durability. Unlike traditional stencils that are often made from paper or cardstock, mylar stencils are made from a durable, heat-resistant material that can withstand heavy use. This means that artists and craftspeople can use their stencils over and over again, without worrying about wear and tear.Furthermore, the precision of laser-cut mylar stencils allows for incredibly detailed designs. Whether it's intricate lettering, delicate floral patterns, or complex geometric shapes, these stencils can capture even the smallest details with stunning accuracy. This level of precision opens up a world of possibilities for artists and craftspeople, allowing them to create designs that were previously out of reach.Another major advantage of laser-cut mylar stencils is their versatility. These stencils can be used on a wide variety of surfaces, including paper, fabric, wood, and more. This means that artists and craftspeople can use their stencils to create a diverse range of projects, from custom t-shirts and tote bags to hand-painted signs and home decor. The possibilities are truly endless.In addition to their durability, precision, and versatility, laser-cut mylar stencils are also incredibly easy to use. The cutouts are clean and sharp, making it easy to achieve crisp, professional-looking designs. Whether you're a seasoned artist or a beginner crafter, these stencils are designed to make the creative process as smooth and straightforward as possible.For crafters and artists looking to take their work to the next level, laser-cut mylar stencils are a game-changer. With their unparalleled precision, durability, and versatility, these stencils are redefining what's possible in the world of art and crafts. And with leading companies like {} leading the way in stencil production, artists and craftspeople can rest assured that they're getting the highest quality products on the market.{}, the industry leader in stencil production, has been at the forefront of this revolution, providing artists and craftspeople with access to the most advanced stencil technology available. With a commitment to quality and an unwavering dedication to innovation, {} has earned a reputation as the go-to source for laser-cut mylar stencils. Its extensive range of designs, customizable options, and exceptional customer service make it the top choice for artists and craftspeople worldwide.In conclusion, laser-cut mylar stencils have ushered in a new era of possibility for artists and craftspeople. With their unmatched precision, durability, versatility, and ease of use, these stencils are empowering creatives to bring their visions to life with unprecedented accuracy and detail. And with companies like {} leading the way, the future of stenciling in the art and crafts industry looks brighter than ever.

Cutting-Edge Technology: The Advantages of Flexible Printed Boards

Flexible Printed Board Market Expected to Grow as Demand for Flexible and Lightweight Electronics RisesThe global flexible printed board market is expected to witness significant growth in the coming years due to the increasing demand for flexible and lightweight electronic devices. Flexible printed boards, also known as FPCBs, are highly flexible and can be bent and twisted to fit into small and irregularly shaped spaces, making them ideal for use in a wide range of electronic applications.The market for flexible printed boards is being driven by the growing adoption of flexible electronics in various industries such as consumer electronics, automotive, healthcare, and aerospace. These industries are increasingly using flexible printed boards in applications such as wearables, smartphones, tablets, automotive infotainment systems, medical devices, and aircraft interiors.One company that is at the forefront of this growing market is {}. {} is a leading manufacturer of high-quality flexible printed boards that are used in a wide range of electronic applications. The company's extensive product portfolio includes single-sided, double-sided, and multi-layer flexible printed boards, as well as rigid-flex boards, which combine the benefits of both flexible and rigid printed boards.{}'s flexible printed boards are known for their high reliability, excellent thermal stability, and superior electrical performance. The company's state-of-the-art manufacturing facilities and advanced production processes ensure that its products meet the highest quality standards, making them the preferred choice for many leading companies in the electronics industry.With a strong focus on innovation and technology, {} is constantly pushing the boundaries of what is possible with flexible printed boards. The company's dedicated research and development team is continuously working on developing new materials and processes to further improve the performance and flexibility of its products. This relentless commitment to innovation has enabled {} to stay ahead of the competition and maintain its position as a market leader in the flexible printed board industry.As the demand for flexible and lightweight electronic devices continues to grow, {} is well-positioned to capitalize on this trend and further expand its market presence. The company's strong customer relationships, global distribution network, and commitment to delivering the highest quality products have earned it a reputation as a trusted and reliable partner for companies looking for flexible printed board solutions.In addition to its focus on product quality and innovation, {} is also committed to sustainability and environmental responsibility. The company has implemented stringent environmental management practices and has made significant investments in eco-friendly manufacturing processes to minimize its impact on the environment.Looking ahead, the future looks bright for the flexible printed board market, and {} is poised to play a key role in driving its growth. With its strong focus on innovation, technology, and sustainability, the company is well-equipped to meet the evolving needs of the electronics industry and continue providing cutting-edge flexible printed board solutions to its customers around the world.

How to Perform a Continuity Test and Why It's Important

DC Continuity Test is a vital operation in the field of electrical engineering and maintenance. It is crucial for ensuring the integrity and safety of electrical circuits and equipment. This test is designed to detect any faults or breaks in the continuity of a DC circuit, which could lead to malfunctions or even hazards. DC Continuity Test is performed using a specialized instrument called a digital multimeter, which is capable of measuring the resistance of a circuit. By connecting the multimeter’s probes to the ends of a circuit, engineers can determine whether the circuit is continuous or if there are any breaks in it. This is essential for diagnosing and troubleshooting electrical problems in various applications, including power distribution systems, industrial machinery, and consumer electronics.In the field of electrical maintenance, DC Continuity Test is a routine procedure that helps ensure the safety and reliability of electrical systems. By detecting and rectifying any issues with circuit continuity, engineers can prevent electrical malfunctions and potential hazards. This is especially important in critical infrastructure and industrial settings where electrical failures can have severe consequences.The Dc Continuity Test is one of the many essential services provided by {}. As a leading provider of electrical maintenance and testing solutions, {} has established itself as a trusted partner for businesses across various industries. With a team of highly skilled engineers and technicians, {} is equipped to handle the most complex electrical testing and maintenance tasks, including the Dc Continuity Test.{}’s expertise in electrical testing and maintenance is backed by years of experience and a commitment to quality. The company’s engineers are thoroughly trained in the latest testing techniques and standards, ensuring that they can deliver accurate and reliable results for their clients. From routine equipment testing to comprehensive maintenance programs, {} offers a wide range of services to meet the diverse needs of its clients.In addition to its technical expertise, {} is also known for its commitment to safety and compliance. The company adheres to the highest industry standards and regulations, ensuring that its testing and maintenance services are conducted in a safe and responsible manner. With a focus on precision and attention to detail, {} strives to exceed its clients’ expectations and deliver the highest level of service.One of {}’s key strengths is its ability to adapt to the evolving needs of the industry. The company constantly invests in research and development to stay ahead of the curve and offer cutting-edge solutions to its clients. This proactive approach has allowed {} to remain a leader in the field of electrical testing and maintenance, providing innovative services such as the Dc Continuity Test to meet the growing demands of its clients.In conclusion, the Dc Continuity Test is a critical operation in the field of electrical engineering and maintenance, and {} is a trusted provider of this essential service. With a strong commitment to quality, safety, and innovation, {} is well-positioned to meet the diverse needs of businesses across various industries. Whether it’s routine testing or comprehensive maintenance programs, {} offers a comprehensive range of services to ensure the integrity and reliability of electrical systems.