Understanding the difference between rigid and flexible production methods

By:Admin

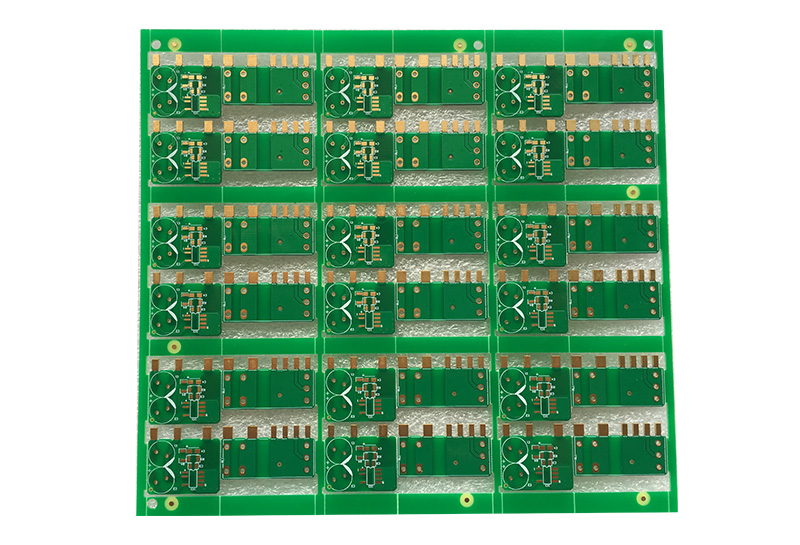

Rigid & Flex Production offers a comprehensive range of services, including design, engineering, and manufacturing of printed circuit boards (PCBs) and related products. Their state-of-the-art facilities are equipped with the latest technology and staffed by a team of highly skilled professionals, ensuring that they can meet the most demanding requirements with precision and efficiency.

One of the key strengths of Rigid & Flex Production is their ability to provide both rigid and flex PCB solutions. Rigid PCBs are the traditional and most widely used type of circuit board, while flex PCBs offer greater flexibility and are ideal for applications with space and weight constraints. By offering both options, Rigid & Flex Production can cater to a broad spectrum of customer needs and deliver tailored solutions for diverse projects.

The company's commitment to quality is evident in their rigorous quality control processes and adherence to industry standards. They are certified to ISO standards and comply with all relevant regulations, giving their customers peace of mind that their products are of the highest standard. Rigid & Flex Production also places a strong emphasis on continuous improvement, constantly investing in their facilities and refining their processes to stay at the forefront of technological advancements.

In addition to their manufacturing capabilities, Rigid & Flex Production also provides comprehensive design and engineering services. Their team of experienced engineers can work closely with customers to develop custom solutions that meet their specific requirements. Whether it's a complex multilayer rigid PCB or a flexible PCB for a specialized application, Rigid & Flex Production has the expertise and resources to deliver top-notch results.

Furthermore, Rigid & Flex Production is committed to sustainability and environmental responsibility. They strive to minimize their impact on the environment by adhering to strict environmental standards and implementing eco-friendly practices in their operations. This commitment to sustainability not only benefits the environment but also reflects positively on their customers who prioritize ethical and responsible suppliers.

The company's focus on innovation and customer satisfaction has earned them a strong reputation in the industry. They have built enduring partnerships with a wide range of clients across various sectors, from aerospace and medical devices to telecommunications and consumer electronics. Their track record of delivering high-quality products on time and on budget has made them a preferred supplier for many leading companies.

Looking ahead, Rigid & Flex Production is poised for further growth and success. With the increasing demand for advanced electronic solutions, the company is well-positioned to capitalize on new opportunities and expand their market presence. Their ongoing commitment to excellence and customer-centric approach will undoubtedly fuel their continued success in the dynamic and competitive electronics manufacturing industry.

Company News & Blog

How to Perform a Continuity Test and Why It's Important

DC Continuity Test is a vital operation in the field of electrical engineering and maintenance. It is crucial for ensuring the integrity and safety of electrical circuits and equipment. This test is designed to detect any faults or breaks in the continuity of a DC circuit, which could lead to malfunctions or even hazards. DC Continuity Test is performed using a specialized instrument called a digital multimeter, which is capable of measuring the resistance of a circuit. By connecting the multimeter’s probes to the ends of a circuit, engineers can determine whether the circuit is continuous or if there are any breaks in it. This is essential for diagnosing and troubleshooting electrical problems in various applications, including power distribution systems, industrial machinery, and consumer electronics.In the field of electrical maintenance, DC Continuity Test is a routine procedure that helps ensure the safety and reliability of electrical systems. By detecting and rectifying any issues with circuit continuity, engineers can prevent electrical malfunctions and potential hazards. This is especially important in critical infrastructure and industrial settings where electrical failures can have severe consequences.The Dc Continuity Test is one of the many essential services provided by {}. As a leading provider of electrical maintenance and testing solutions, {} has established itself as a trusted partner for businesses across various industries. With a team of highly skilled engineers and technicians, {} is equipped to handle the most complex electrical testing and maintenance tasks, including the Dc Continuity Test.{}’s expertise in electrical testing and maintenance is backed by years of experience and a commitment to quality. The company’s engineers are thoroughly trained in the latest testing techniques and standards, ensuring that they can deliver accurate and reliable results for their clients. From routine equipment testing to comprehensive maintenance programs, {} offers a wide range of services to meet the diverse needs of its clients.In addition to its technical expertise, {} is also known for its commitment to safety and compliance. The company adheres to the highest industry standards and regulations, ensuring that its testing and maintenance services are conducted in a safe and responsible manner. With a focus on precision and attention to detail, {} strives to exceed its clients’ expectations and deliver the highest level of service.One of {}’s key strengths is its ability to adapt to the evolving needs of the industry. The company constantly invests in research and development to stay ahead of the curve and offer cutting-edge solutions to its clients. This proactive approach has allowed {} to remain a leader in the field of electrical testing and maintenance, providing innovative services such as the Dc Continuity Test to meet the growing demands of its clients.In conclusion, the Dc Continuity Test is a critical operation in the field of electrical engineering and maintenance, and {} is a trusted provider of this essential service. With a strong commitment to quality, safety, and innovation, {} is well-positioned to meet the diverse needs of businesses across various industries. Whether it’s routine testing or comprehensive maintenance programs, {} offers a comprehensive range of services to ensure the integrity and reliability of electrical systems.

High Voltage Spark Testing: What You Need to Know

Spark Test Voltage is a vital part of the quality control process for a wide range of products and materials. It is used to determine the dielectric breakdown voltage of insulating oils and fluids, as well as the electrical insulation of electrical equipment such as transformers, cables, and switchgear. This test is crucial for ensuring the safety and reliability of these products and materials, and it is an essential part of the overall quality control process.The [Company] is a leading provider of high-quality testing and measurement equipment for a wide range of industries. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted provider of reliable and accurate testing solutions. The [Company] has a long history of providing top-quality products and services to its customers, and its commitment to excellence has made it a preferred choice for many businesses around the world.One of the [Company]'s flagship products is its Spark Test Voltage equipment, which is widely used in the electrical and power industries. This equipment is designed to accurately measure the dielectric breakdown voltage of insulating oils and fluids, as well as the electrical insulation of various types of electrical equipment. With its advanced technology and precision engineering, the [Company]'s Spark Test Voltage equipment is known for its reliability, accuracy, and ease of use.The importance of Spark Test Voltage in the quality control process cannot be understated. In the electrical and power industries, the reliability and safety of equipment and materials are of utmost importance. Without accurate and precise testing methods, it would be impossible to ensure that these products and materials meet the necessary standards and requirements. This is where the [Company]'s Spark Test Voltage equipment plays a crucial role, providing businesses with the means to effectively test and measure the dielectric breakdown voltage and electrical insulation of their products and materials.In addition to its reliability and accuracy, the [Company]'s Spark Test Voltage equipment is also highly user-friendly. With intuitive controls and easy-to-read displays, this equipment is designed to be highly accessible to operators of all skill levels. This ensures that businesses can carry out their quality control processes with confidence, knowing that they have a reliable and user-friendly testing solution at their disposal.Moreover, the [Company] also provides exceptional customer support and service, ensuring that businesses can get the most out of their Spark Test Voltage equipment. With a team of knowledgeable and experienced professionals, the company is committed to helping its customers with any questions or issues they may have. This level of support is invaluable to businesses, as it ensures that they can effectively integrate the Spark Test Voltage equipment into their quality control processes and maximize its benefits.The [Company] is continuously innovating and improving its Spark Test Voltage equipment, staying at the forefront of technological advancements and industry standards. This commitment to excellence ensures that businesses have access to the most advanced and reliable testing solutions available, allowing them to meet and exceed the necessary quality control requirements.In conclusion, the [Company]'s Spark Test Voltage equipment is an essential part of the quality control process for numerous industries. Its reliability, accuracy, and user-friendly design make it a preferred choice for businesses around the world. With exceptional customer support and a commitment to innovation, the [Company] is a trusted provider of high-quality testing and measurement solutions, helping businesses ensure the safety and reliability of their products and materials.

- The Latest Advancements in Artificial Intelligence and PCB Technology

Artificial Intelligence PCBs Revolutionizing the Electronics IndustryArtificial intelligence (AI) has become an integral part of many industries, and the electronics sector is no exception. With the increasing demand for smart and connected devices, the need for efficient and intelligent electronics components has never been greater. The introduction of AI-enabled printed circuit boards (PCBs) has brought about a revolution in the electronics industry, offering unprecedented levels of performance, efficiency, and adaptability.One company at the forefront of this revolution is {}. With a proven track record of innovation and excellence, {} has developed cutting-edge AI PCBs that are set to redefine the electronics landscape. By integrating AI technology directly into the PCBs, {} has created a range of products that offer enhanced functionality, improved reliability, and accelerated performance.The integration of AI into PCBs has opened up a world of possibilities for the electronics industry. Traditional PCBs are limited in their ability to adapt to changing conditions, but AI-enabled PCBs have the capability to learn and evolve, making them far more versatile and adaptable. This means that devices equipped with AI PCBs can optimize their performance in real-time, leading to improved energy efficiency, faster processing speeds, and enhanced user experiences.One of the key advantages of AI PCBs is their ability to analyze and interpret data in real-time. By leveraging machine learning algorithms, these PCBs can make sense of complex data sets and make intelligent decisions based on the information they gather. This has significant implications for a wide range of applications, from consumer electronics to industrial automation, where the ability to process and act upon data quickly and accurately is critical.Furthermore, AI PCBs have the potential to revolutionize the concept of predictive maintenance. By continuously monitoring the performance of electronic systems and identifying potential issues before they arise, AI-enabled PCBs can help prevent costly downtime and maintenance issues. This not only improves the reliability of electronic devices but also reduces the total cost of ownership for end-users.In addition to their performance benefits, AI PCBs also have the potential to significantly reduce the environmental impact of electronic devices. By optimizing energy consumption and reducing waste, these PCBs can contribute to the development of more sustainable and eco-friendly electronics.{}'s commitment to innovation and excellence has positioned them as a leader in the development of AI PCBs. Through continuous research and development efforts, they have been able to create a range of AI-enabled PCBs that are not only technologically advanced but also practical and cost-effective.As the demand for smarter and more efficient electronics continues to grow, the role of AI-enabled PCBs in driving this transformation is set to become increasingly significant. By offering unparalleled levels of performance, adaptability, and intelligence, these PCBs are poised to reshape the future of the electronics industry, opening up new possibilities for innovation and advancement.In conclusion, the integration of AI technology into PCBs has ushered in a new era of possibilities for the electronics industry. With their ability to learn, adapt, and make intelligent decisions, AI-enabled PCBs are set to revolutionize the way electronic devices are designed, manufactured, and utilized. As a pioneer in this field, {} is driving this revolution forward, and their AI PCBs are expected to play a crucial role in shaping the future of electronics.

Different Types of Resistors: A Guide to Passive Components

We are pleased to introduce our company, a leading manufacturer of electronic components with a focus on innovation and quality. With over 20 years of experience in the industry, we have established ourselves as a trusted provider of reliable and high-performance components for a wide range of applications.One of our flagship products is the Resistor Passive Component, which has gained a strong reputation for its precision, durability, and performance. Our resistors are designed to meet the highest industry standards and are trusted by engineers and electronic professionals worldwide.Our resistors are available in a variety of configurations, including through-hole, surface mount, and custom designs to meet specific application requirements. We offer a wide range of resistance values, power ratings, and tolerance levels to accommodate the diverse needs of our customers.In addition to standard resistors, we also offer specialized products such as high-voltage resistors, high-temperature resistors, and precision resistors for applications that demand exceptional performance under challenging conditions.Our commitment to quality is evident in our state-of-the-art manufacturing facilities, where we employ the latest technologies and stringent quality control measures to ensure that every resistor that leaves our facility meets our high standards. We also have a dedicated team of engineers and technical experts who are continuously working to develop new and improved resistor products to meet the evolving demands of the industry.Furthermore, we understand the importance of environmental sustainability, and all of our resistor products are designed to comply with the latest regulations and standards for environmental safety and sustainability.In line with our commitment to customer satisfaction, we provide comprehensive technical support and customer service to assist our clients in selecting the right resistor for their specific needs. Our team of experienced professionals is always ready to provide guidance and support to ensure that our customers receive the best solution for their applications.As part of our ongoing efforts to expand our global presence, we are continuously seeking new partnerships and collaborations with distributors and manufacturers worldwide. Our aim is to make our high-quality resistor products accessible to a broader customer base and to establish long-term relationships with partners who share our commitment to excellence and customer satisfaction.In conclusion, our Resistor Passive Component is a testament to our dedication to quality, innovation, and customer satisfaction. We are proud to offer a comprehensive range of resistor products that meet the diverse needs of the electronic industry and to provide exceptional support and service to our customers.We invite you to explore our range of resistor products and experience the difference that our commitment to excellence can make for your electronic applications. Thank you for considering our company as your trusted partner for high-quality resistor passive components.

Quick and Easy Replacements with Short Lead Times

Short Lead Time Replacements, a global leader in providing high-quality replacement parts for various industries, has announced the launch of its new line of products with even shorter lead times. With a strong focus on customer satisfaction and efficiency, the company aims to provide quick and reliable solutions for companies in need of replacement parts.With a wide range of products designed to suit the needs of various industries, Short Lead Time Replacements has built a reputation for its high-quality and reliable parts. Whether it's for automotive, manufacturing, or construction, the company has become a trusted partner for businesses around the world.The company's dedication to innovation and customer satisfaction has enabled it to stay ahead of the competition. By continuously improving its production processes and investing in cutting-edge technology, Short Lead Time Replacements has been able to reduce lead times for its products, making it easier and faster for companies to get the replacement parts they need.Short Lead Time Replacements has also made significant strides in improving its supply chain management, allowing for better coordination and faster delivery of its products. This has not only reduced lead times but also increased the overall efficiency of the company's operations.In addition to its focus on efficiency, Short Lead Time Replacements is also committed to providing the highest level of quality in its products. The company adheres to strict quality control measures to ensure that every part meets the highest industry standards. This dedication to quality has earned Short Lead Time Replacements the trust and loyalty of its customers."Providing quick and reliable replacement parts is essential for businesses to minimize downtime and keep their operations running smoothly," said a company spokesperson. "We understand the importance of getting the right parts quickly, which is why we have worked hard to reduce lead times and improve our supply chain management. Our new line of products with shorter lead times is a testament to our commitment to providing the best possible solutions for our customers."Short Lead Time Replacements' new line of products with shorter lead times is expected to have a significant impact on the industries it serves. With the ability to get critical parts faster and more efficiently, companies can reduce downtime, improve productivity, and ultimately, save money.The company's dedication to innovation, efficiency, and quality has positioned it as a leader in the replacement parts industry. Its ability to provide quick and reliable solutions has made it a go-to partner for businesses around the world. As Short Lead Time Replacements continues to push the boundaries of what's possible in the industry, it is expected to remain a key player for years to come.

Top Tips for Medical PCB Fabricating

Medical PCB Fabricating Company () Leads the Way in Healthcare TechnologyThe demand for advanced healthcare technology is increasing rapidly, and one company is at the forefront of meeting this demand. With an unwavering commitment to innovation and quality, the company has established itself as a leader in medical PCB fabricating. This has not only revolutionized the healthcare industry but has also played a crucial role in improving patient care across the globe.The company, based in (), has been in the business of fabricating PCBs for medical devices for over two decades. With a team of highly skilled engineers and cutting-edge technology, they have been able to meet the stringent requirements of the medical industry. From designing and prototyping to manufacturing and testing, the company has always been committed to delivering superior quality PCBs for medical devices.As a key player in the healthcare technology industry, the company has worked with leading healthcare organizations to develop PCBs for a wide range of medical devices. From diagnostic equipment and imaging devices to patient monitoring systems and treatment machines, they have played a crucial role in the advancement of healthcare technology. With a deep understanding of the unique needs of the medical industry, the company has been able to develop PCBs that meet the highest standards of quality and reliability.One of the key factors that set the company apart from its competitors is its focus on research and development. With a dedicated R&D team, the company has been able to stay ahead of the curve when it comes to technological advancements in healthcare. This has enabled them to design and fabricate PCBs that not only meet the current needs of the healthcare industry but also have the potential to shape the future of medical technology.In addition to their commitment to innovation, the company also places a strong emphasis on quality control. With a state-of-the-art manufacturing facility and a rigorous quality assurance process, they ensure that every PCB that leaves their facility meets the highest standards of quality and reliability. This has not only earned them the trust of their clients but has also contributed to their reputation as a reliable and reputable PCB fabricating company.The company's success in the healthcare industry can also be attributed to their customer-centric approach. They work closely with their clients to understand their specific needs and requirements, and then tailor their PCB fabrication process to meet those needs. This has enabled them to build strong and long-lasting relationships with their clients and has cemented their position as a trusted partner in the healthcare technology industry.Furthermore, the company has also been proactive in addressing the evolving regulatory requirements in the medical industry. With a comprehensive understanding of the regulatory landscape, they have been able to ensure that their PCBs comply with the strict standards set by regulatory bodies. This has been crucial in enabling their clients to navigate the complex regulatory environment and bring their medical devices to market with confidence.Looking ahead, the company remains committed to pushing the boundaries of healthcare technology. With a focus on continuous innovation and a dedication to meeting the evolving needs of the medical industry, they are well-positioned to lead the way in the future of medical PCB fabricating. As the demand for advanced medical devices continues to grow, the company stands ready to play a pivotal role in shaping the future of healthcare technology.In conclusion, the company's dedication to innovation, quality, and customer-centric approach has enabled them to establish themselves as a leader in medical PCB fabricating. With a strong track record of delivering high-quality PCBs for medical devices, they have played a crucial role in driving advancements in healthcare technology. As they continue to push the boundaries of innovation and quality, the company is well-positioned to remain at the forefront of the healthcare technology industry.

How to Choose the Best Electronic Assembly PCB for Your Needs

Electronic Assembly PCB, a leader in the PCB manufacturing industry, has announced the release of their latest product line that promises to revolutionize the electronic assembly process. With a focus on innovation and quality, Electronic Assembly PCB has been at the forefront of the industry for over a decade, providing cutting-edge solutions for a wide range of electronic applications.The latest product line from Electronic Assembly PCB includes a range of advanced PCBs that are designed to meet the demands of modern electronic devices. These PCBs are manufactured using the latest technology and are built to the highest standards, ensuring reliability and performance.One of the key features of the new product line is the use of advanced materials and construction techniques, which result in PCBs that are not only smaller and lighter, but also more durable and reliable. This is crucial for electronic devices that are becoming increasingly compact and portable, and demand PCBs that can withstand harsh operating conditions.In addition to their focus on technological innovation, Electronic Assembly PCB also places a strong emphasis on environmental sustainability and ethical manufacturing practices. The company is committed to reducing its environmental impact and operates in compliance with strict environmental regulations. They also ensure that their manufacturing processes are ethical and responsible, and they have implemented strict quality control measures to guarantee the safety and reliability of their products.Electronic Assembly PCB's dedication to excellence and customer satisfaction is evident in their state-of-the-art manufacturing facilities, which are equipped with the latest machinery and technology. Their team of highly skilled and experienced engineers and technicians work tirelessly to ensure that each PCB meets the highest standards of quality and performance.With a commitment to customer satisfaction, Electronic Assembly PCB provides comprehensive support and customization options to meet the unique needs of their clients. They work closely with their customers to understand their specific requirements and provide tailored solutions that meet or exceed their expectations.The release of the new product line from Electronic Assembly PCB is expected to have a significant impact on the electronic assembly industry, as it introduces a new standard of performance, reliability, and sustainability. With their state-of-the-art technology, commitment to quality and customer satisfaction, Electronic Assembly PCB is well-positioned to continue leading the way in the PCB manufacturing industry.In conclusion, Electronic Assembly PCB's latest product line showcases their unwavering commitment to innovation, quality, and customer satisfaction. With a strong focus on technological advancement, environmental sustainability, and ethical manufacturing practices, the company continues to set the bar for excellence in the electronic assembly industry. Their new product line is set to redefine the standards for PCB manufacturing, and further solidify their position as a leader in the industry.

Dielectric Test: What It Is and How It Works

We are pleased to announce that our company has recently developed a cutting-edge Hipot Dielectric Test system, which is set to revolutionize the electrical testing industry. This innovative technology is the result of years of research and development, and we are proud to offer it to our clients as part of our comprehensive range of testing solutions.The Hipot Dielectric Test is a crucial part of the quality control process for electrical components and equipment. This test is designed to evaluate the insulation strength of a product by applying a high voltage to it and measuring the amount of current that is able to flow through the insulation. By subjecting an electrical component to a high voltage for a sustained period of time, the test can identify any potential weaknesses or defects in the insulation, helping to ensure the safety and reliability of the product.Our new Hipot Dielectric Test system is equipped with state-of-the-art technology that allows for highly accurate and reliable testing. It is capable of generating high voltages and measuring current with a high degree of precision, and its automated testing process ensures consistency and repeatability from test to test. This level of accuracy and reliability is essential for identifying even the smallest defects in insulation, and our system is designed to meet the most stringent quality standards.In addition to its advanced technology, our Hipot Dielectric Test system is also designed with user-friendliness in mind. The intuitive interface and easy-to-use controls make it simple for operators to set up and run tests, and the system is equipped with comprehensive safety features to protect operators and equipment during testing. This combination of advanced technology and user-friendly design makes our Hipot Dielectric Test system a valuable addition to any testing facility.Our company has a long history of providing high-quality testing solutions to a wide range of industries. We have established ourselves as a trusted partner for companies looking to ensure the quality and safety of their electrical products, and our commitment to innovation has allowed us to stay at the forefront of the industry. With the introduction of our new Hipot Dielectric Test system, we are proud to continue this tradition of excellence and to offer our clients the most advanced testing technology available.In addition to our new Hipot Dielectric Test system, we offer a comprehensive range of testing solutions to meet the needs of our clients. Our portfolio includes insulation resistance testing, ground continuity testing, and more, all of which are designed to help our clients ensure the safety and reliability of their electrical products. We also offer custom testing solutions to meet specific requirements, and our team of experts is dedicated to providing the highest level of support and service to our clients.We are confident that our new Hipot Dielectric Test system will set a new standard for electrical testing technology, and we are excited to offer this innovative solution to our clients. With its advanced technology, user-friendly design, and comprehensive support, our system is the ideal choice for companies looking to ensure the quality and safety of their electrical products. We are committed to continuing our tradition of excellence and innovation, and we look forward to helping our clients achieve their testing goals with our new Hipot Dielectric Test system.

How to Solder Surface Mount PCBs: Expert Techniques and Tips

In the world of electronics manufacturing, surface mount PCB soldering is a critical process that can greatly impact the performance and reliability of electronic devices. With the advancement of technology, the demand for high-quality surface mount PCB soldering services has been on the rise. This need has been efficiently met by the reputable company, {}.{} has established itself as a leading provider of electronic manufacturing services, specializing in surface mount PCB assembly and soldering. With state-of-the-art facilities and a highly skilled team, the company has earned a reputation for delivering superior quality products and services to a wide range of industries including automotive, medical, aerospace, and consumer electronics.Surface mount PCB soldering is a complex process that requires precision and expertise. {} understands the importance of this process and has invested in advanced equipment and technology to ensure that their surface mount PCB soldering services meet the highest standards of quality and reliability.The company's surface mount PCB soldering process begins with the careful inspection and preparation of the PCBs. Using automated equipment, the surface mount components are accurately placed on the PCBs with utmost precision. Once the components are in place, the PCBs undergo a meticulous soldering process to create strong and reliable connections.One of the key factors that sets {} apart from its competitors is its commitment to using the latest soldering techniques and materials. The company stays updated with industry standards and advancements to ensure that their soldering processes meet the ever-evolving demands of their clients.In addition to using cutting-edge technology, {} also emphasizes the importance of quality control. The company has implemented rigorous inspection and testing procedures to guarantee that the soldering process has been carried out flawlessly. This attention to detail has enabled {} to consistently deliver surface mount PCBs that meet the strictest performance requirements.Furthermore, {} takes pride in its team of highly skilled and experienced technicians. The company provides regular training and encourages continuous improvement to ensure that its employees are well-equipped to handle the most complex soldering challenges. This dedication to excellence has earned {} the trust and confidence of its clients, who rely on the company to deliver top-notch surface mount PCB soldering solutions.As a responsible corporate citizen, {} is also committed to sustainability and environmental responsibility. The company adheres to strict environmental standards in all facets of its operations, including its surface mount PCB soldering processes. By using eco-friendly materials and implementing efficient manufacturing practices, {} minimizes its environmental impact while continuing to provide exceptional products and services.In conclusion, {} has positioned itself as a premier provider of surface mount PCB soldering services, catering to the diverse needs of the electronics manufacturing industry. With its unwavering commitment to quality, innovation, and customer satisfaction, {} continues to be a trusted partner for businesses seeking reliable and high-performance electronic manufacturing solutions.

Top Active Electronic Devices for Improved Performance

Active Electronic Devices, a leader in innovative and cutting-edge technology, has recently announced a groundbreaking development in the field of electronic devices. The company, known for its expertise in producing high-quality electronic devices, has introduced a new line of products that are set to revolutionize the industry.Active Electronic Devices has always been at the forefront of technological advancements, constantly pushing the boundaries of what is possible in the electronic devices market. With the introduction of their latest line of products, the company is poised to further cement its position as a frontrunner in the industry.The new line of products offered by Active Electronic Devices comprises a wide range of electronic devices, including but not limited to smartphones, tablets, laptops, and wearable technology. Each product is designed with state-of-the-art technology and features that are geared towards enhancing user experience and providing unparalleled performance.One of the key highlights of this new line of products is the incorporation of advanced technology that allows for seamless connectivity and integration across different devices. This means that users can easily switch between their smartphone, tablet, and laptop without any hassle, ensuring a smooth and efficient user experience.In addition to this, Active Electronic Devices has also focused on improving the battery life and charging capabilities of their devices. With advancements in battery technology, users can expect their devices to have longer battery life, reducing the need for frequent charging. Furthermore, the introduction of fast-charging technology ensures that users can quickly replenish their device's battery, minimizing downtime.Another noteworthy feature of the new product line is the emphasis on security and privacy. Active Electronic Devices has incorporated robust security measures into their devices to safeguard user data and privacy. This includes biometric authentication, encrypted communication, and secure storage, providing users with the peace of mind that their personal information is well-protected.Furthermore, the aesthetics and design of the new products have also been given a significant amount of attention. Active Electronic Devices has employed a team of talented designers to create sleek, modern, and stylish devices that not only perform exceptionally well but also look visually appealing. With a focus on premium materials and attention to detail, the new line of products from Active Electronic Devices is set to turn heads in the market.In terms of performance, the new products from Active Electronic Devices are powered by cutting-edge processors and hardware that deliver outstanding performance. Whether it's seamless multitasking, demanding gaming applications, or resource-intensive workloads, users can expect exceptional performance from these devices.As a company, Active Electronic Devices has always been committed to delivering products that exceed customer expectations. With a strong emphasis on research and development, the company has consistently pushed the boundaries of what is possible, resulting in the creation of innovative products that redefine the industry standards.In line with this commitment to innovation, Active Electronic Devices has also invested heavily in customer support and after-sales service. The company understands the importance of providing comprehensive support to its customers, and has established a robust customer service infrastructure to cater to their needs.Active Electronic Devices has also prioritized sustainability and environmental responsibility in the production of its new line of products. The company has taken significant strides to minimize the environmental impact of its operations and products, ensuring that they are eco-friendly and adhere to the highest standards of sustainability.In conclusion, the introduction of the new line of products by Active Electronic Devices is a testament to the company's dedication to innovation and excellence. With a focus on technological advancements, user experience, security, and sustainability, the new products are set to make a significant impact in the electronic devices market. Active Electronic Devices continues to set the bar high for the industry and is poised to maintain its position as a leader in the field of electronic devices.