Ultimate Guide to Pcb Rigid Flex: Everything You Need to Know

By:Admin

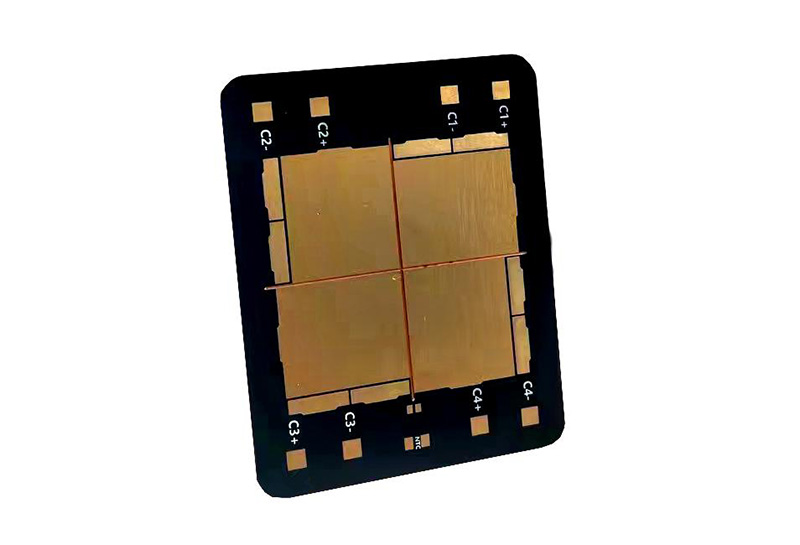

[Company Name] is known for its cutting-edge advancements in PCB technology, and recently they have unveiled their latest innovation in the form of a PCB rigid flex. This new product is set to revolutionize the industry by offering a unique combination of flexibility and durability, allowing for greater design possibilities and improved performance.

The PCB rigid flex is designed to deliver the best of both worlds – the flexibility of a flexible PCB and the rigidity of a traditional PCB. This hybrid design allows for improved reliability and durability, making it ideal for a wide range of applications, including aerospace, medical devices, automotive, and consumer electronics.

One of the key advantages of [Company Name]'s PCB rigid flex is its ability to reduce the need for complex interconnects and connectors, thereby improving the overall reliability of the technology. This can result in cost savings for manufacturers, as well as improved performance and longevity for end-users.

In addition to its innovative design, the PCB rigid flex from [Company Name] is also manufactured using the latest materials and techniques, ensuring the highest level of quality and performance. The company has invested heavily in research and development to create a product that meets the stringent demands of the industry.

The introduction of the PCB rigid flex is a testament to [Company Name]'s commitment to pushing the boundaries of PCB technology. With a team of highly skilled engineers and designers, the company is constantly pushing the envelope in terms of what is possible in the world of electronics.

“We are thrilled to introduce our latest innovation in PCB technology,” said [Spokesperson Name], CEO of [Company Name]. “The PCB rigid flex represents a significant leap forward in terms of what is possible in the industry, and we are excited to see the impact it will have on our customers and the wider electronics market.”

The PCB rigid flex from [Company Name] is already generating significant interest from industry leaders and experts, who recognize the potential impact it could have on the industry. With its unique combination of flexibility and rigidity, this new product is set to open up a whole new world of possibilities for electronics manufacturers and designers.

In conclusion, the introduction of the PCB rigid flex from [Company Name] is set to revolutionize the industry by offering a unique combination of flexibility and durability. With its innovative design and high-quality manufacturing, this product is poised to set new standards for PCB technology and redefine what is possible in the world of electronics. As the demand for flexible and high-performance electronics continues to grow, [Company Name] is at the forefront of delivering the solutions that are needed to drive the industry forward.

Company News & Blog

Top Tips for Choosing the Best Circuit Card Assembly in 2022

Circuit Card Assy, commonly known as CCA, is a critical component in a wide range of electronic devices. From consumer electronics to industrial machinery, CCAs are essential for ensuring the proper functioning of these devices. One company that has made a name for itself in the CCA manufacturing industry is a global leader in electronic manufacturing services. With a strong focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for businesses across various industries.The company's commitment to excellence is evident in its state-of-the-art manufacturing facilities and dedicated team of engineers and technicians. With a keen understanding of the latest technological advancements and market trends, the company continuously strives to develop cutting-edge CCAs that meet the evolving needs of its customers. This dedication to innovation has enabled the company to stay ahead of the competition and maintain its position as a leader in the electronic manufacturing industry.One of the key factors that set the company apart from its competitors is its unwavering commitment to quality. The company adheres to the highest industry standards and rigorous quality control processes to ensure that its CCAs meet the strictest performance and reliability requirements. This dedication to quality has earned the company numerous certifications and accolades, further solidifying its reputation as a trusted and reliable partner for electronic manufacturing services.In addition to quality, the company places a strong emphasis on customer satisfaction. By working closely with its clients and understanding their unique requirements, the company is able to deliver tailored solutions that address specific needs and challenges. Whether it's a custom-designed CCA for a niche market or a high-volume production run for a popular consumer electronics product, the company has the expertise and resources to deliver superior results.Furthermore, the company's commitment to sustainability and corporate responsibility sets it apart as a leader in the electronic manufacturing industry. By integrating eco-friendly practices into its operations and supply chain, the company strives to minimize its environmental impact and reduce its carbon footprint. This initiative not only benefits the planet but also aligns with the sustainability goals of its clients, making it an attractive partner for businesses looking to reduce their environmental impact.As the demand for electronic devices continues to grow, the company remains at the forefront of the industry, driving innovation and delivering high-quality CCAs to meet the needs of its diverse customer base. Whether it's a complex multi-layer CCA for a cutting-edge medical device or a simple circuit board for a consumer electronic product, the company has the expertise and capabilities to deliver top-notch solutions that exceed expectations.With a strong track record of success and a commitment to excellence, the company is poised to continue leading the electronic manufacturing industry for years to come. Its dedication to innovation, quality, customer satisfaction, and sustainability sets it apart as a trusted partner for businesses looking for superior electronic manufacturing services. As the industry evolves, the company remains steadfast in its mission to drive progress and deliver exceptional CCAs that power the electronic devices of today and tomorrow.

High-quality PCB Assembly Services: Fast Turnaround and Competitive Prices

Order Pcb Assembly is a leading provider of PCB assembly services, specializing in high-quality printed circuit board assemblies for a wide range of industries. With state-of-the-art manufacturing facilities and a team of experienced professionals, Order Pcb Assembly is committed to delivering exceptional results to its clients.Order Pcb Assembly operates with a customer-centric approach, always striving to understand the unique needs and requirements of each client. By providing personalized solutions and superior customer service, the company has built a strong reputation for reliability and excellence in the PCB assembly industry.The company’s dedication to quality and innovation is evident in its cutting-edge manufacturing capabilities. Order Pcb Assembly utilizes advanced equipment and technology to ensure the precise assembly of PCBs, meeting the highest industry standards. From prototype to production volumes, the company has the expertise to handle projects of any scale with efficiency and precision.In addition to its technical expertise, Order Pcb Assembly is committed to upholding the highest standards of quality control and inspection. Every step of the assembly process is carefully monitored and tested to guarantee the reliability and functionality of the final product. This commitment to quality has earned the trust of clients from a diverse range of industries, including aerospace, automotive, medical, and telecommunications.One of the key strengths of Order Pcb Assembly is its ability to provide turnkey solutions to its clients. From PCB design and layout to procurement and assembly, the company offers a comprehensive suite of services to streamline the manufacturing process and reduce time-to-market for its clients. This integrated approach allows for greater efficiency and cost-effectiveness, making Order Pcb Assembly a trusted partner for businesses seeking reliable PCB assembly solutions.As a trusted industry leader, Order Pcb Assembly is known for its dedication to customer satisfaction and its ability to meet the unique needs of each client. The company’s team of professionals works closely with clients to understand their specific requirements and develop tailored solutions that optimize their manufacturing processes. With a focus on delivering exceptional results, Order Pcb Assembly has established long-lasting partnerships with clients who appreciate the company’s commitment to excellence.Beyond its technical expertise, Order Pcb Assembly is also committed to environmental sustainability and ethical manufacturing practices. The company adheres to strict environmental regulations and operates with a focus on minimizing its environmental impact. This commitment to sustainability is reflected in the company’s manufacturing processes, which prioritize energy efficiency and waste reduction.In conclusion, Order Pcb Assembly is a trusted leader in the PCB assembly industry, known for its commitment to quality, innovation, and customer satisfaction. With its advanced manufacturing capabilities, dedication to quality control, and turnkey solutions, the company has established itself as a reliable partner for businesses seeking high-quality PCB assembly services. Through its customer-centric approach and ethical manufacturing practices, Order Pcb Assembly continues to deliver exceptional results to clients from a diverse range of industries, solidifying its position as an industry leader.

Efficient Aerospace PCB Assembly for Improved Performance

Aerospace PCB Assembly: A Step Forward in Cutting-Edge TechnologyIn today's fast-paced world, technological advancements are crucial for the aerospace industry. One such advancement is the Aerospace PCB Assembly, which is deemed as a significant breakthrough in the world of electronics and technology. The Assembly is set to change the way aerospace companies operate and innovate, bringing a new wave of cutting-edge technology to the industry.The Aerospace PCB Assembly is a specialized service, offering high-quality printed circuit board assembly designed specifically for the rigorous demands of the aerospace and defense industry. With stringent requirements for reliability, durability, and precision, the Aerospace PCB Assembly is the perfect fit for aerospace and defense applications.With a focus on advanced technology and innovation, {} has emerged as a leader in Aerospace PCB Assembly. The company is committed to delivering high-performance, high-reliability PCB assemblies that meet the unique needs of the aerospace and defense sector. With its state-of-the-art facilities and a team of experienced professionals, {} is well-equipped to provide top-notch Aerospace PCB Assembly services to its clients.{} has a track record of providing cutting-edge solutions for the aerospace industry. Their expertise in aerospace PCB assembly enables them to meet the demanding requirements of this industry, including stringent quality and reliability standards, as well as compliance with regulatory requirements. With a focus on precision and attention to detail, {} ensures that their Aerospace PCB Assembly services are second to none.The Aerospace PCB Assembly services offered by {} are tailored to the specific needs of each client. Whether it's a small startup or a multinational aerospace corporation, {} is capable of delivering bespoke solutions to meet the most challenging requirements. The company's commitment to excellence and customer satisfaction has earned them a stellar reputation in the aerospace and defense industry.The Aerospace PCB Assembly is a critical component in the aerospace industry, where reliability and performance are of utmost importance. With {}'s expertise in this field, aerospace companies can rest assured that they are getting the best-in-class PCB assemblies for their applications. Whether it's for avionics, communication systems, or other mission-critical aerospace equipment, {}'s Aerospace PCB Assembly services are designed to meet and exceed the industry's strictest standards.In addition to their expertise in Aerospace PCB Assembly, {} also offers a range of other services to support the aerospace and defense industry. From design and prototyping to testing and validation, {} provides a comprehensive suite of services to meet the diverse needs of its clients. With a customer-centric approach and a commitment to excellence, {} is well-positioned to drive innovation and advancement in the aerospace industry.As the aerospace industry continues to evolve, the demand for cutting-edge technology and reliable solutions is on the rise. The Aerospace PCB Assembly by {} represents a significant step forward in meeting these demands. With its focus on precision, reliability, and performance, {} is poised to make a lasting impact on the aerospace and defense sector, offering a new standard of excellence in PCB assembly services.

Top 10 Types of Electrical Components for Active Devices

Active Electrical Components, a leading provider of innovative electrical components for the automotive industry, has recently announced the launch of a new line of cutting-edge products designed to enhance vehicle performance and efficiency. With a strong focus on research and development, the company has developed a reputation for delivering high-quality solutions that meet the evolving needs of the automotive market.Established in 1985, Active Electrical Components has been at the forefront of the automotive electronics industry for over three decades. The company's commitment to excellence and innovation has propelled them to become a trusted partner for OEMs and aftermarket suppliers worldwide. With a dedicated team of engineers and technical experts, Active Electrical Components has continuously pushed the boundaries of technology to deliver reliable and efficient electrical components for various automotive applications.The latest product line from Active Electrical Components includes advanced ignition coils, voltage regulators, and electronic control modules, among other components. These products are designed to optimize the performance of modern vehicles, providing better fuel efficiency, improved emissions control, and overall enhanced driving experience. With a focus on durability and reliability, these components are built to withstand the rigors of daily use and harsh environmental conditions, delivering consistent performance and long service life."We are excited to introduce our latest line of electrical components that are engineered to meet the demands of today's automotive industry," said the spokesperson for Active Electrical Components. "With the increasing focus on sustainability, efficiency, and performance, our products are designed to help automakers and aftermarket suppliers deliver vehicles that exceed customer expectations."The new ignition coils, for example, are designed to deliver precise ignition timing and optimal spark energy, resulting in improved engine power, better fuel economy, and reduced emissions. These coils are built using advanced materials and manufacturing processes to ensure reliability and performance under all operating conditions. Similarly, the voltage regulators and electronic control modules are engineered to provide stable voltage output and precise control of electrical systems, contributing to the overall efficiency and reliability of the vehicle.Active Electrical Components has also invested heavily in research and development to ensure that their products comply with the latest industry standards and regulations. The company maintains state-of-the-art testing facilities to validate the performance and durability of their components, ensuring that they meet or exceed the requirements of automotive manufacturers and industry regulations.In addition to their dedication to product excellence, Active Electrical Components is committed to fostering strong partnerships with their customers. The company works closely with OEMs and aftermarket suppliers to understand their specific needs and challenges, providing customized solutions that address their unique requirements. This collaborative approach has enabled Active Electrical Components to build long-term relationships with customers and to establish a reputation for exceptional customer service and technical support.As the automotive industry continues to evolve with the introduction of electric and autonomous vehicles, Active Electrical Components remains at the forefront of innovation. The company is actively exploring new technologies and solutions to support the transition to electrification and autonomy, leveraging their extensive experience and technical expertise to develop cutting-edge components that support the next generation of vehicles.With the introduction of their latest line of advanced electrical components, Active Electrical Components reaffirms their commitment to driving innovation and delivering solutions that empower the automotive industry to meet the challenges of the future. The company's relentless pursuit of excellence and customer satisfaction positions them as a key player in the global automotive electronics market, and their latest products are poised to make a significant impact on the industry's continued advancement.

New Thin Circuit Board Offers Revolutionary Advancements in Technology

[Company name] Unveils Groundbreaking Thin Circuit Board Technology[City, Date] - [Company name], a leading provider of advanced technology solutions, has recently announced the release of their new ultra-thin circuit board. This revolutionary technology is set to disrupt the electronics industry, offering unprecedented flexibility and efficiency in a variety of applications.The ultra-thin circuit board, which measures just a fraction of the thickness of traditional boards, is the result of years of research and development by [Company name]'s team of engineers and scientists. By leveraging cutting-edge materials and manufacturing techniques, they have been able to create a circuit board that is not only incredibly thin, but also highly durable and reliable.One of the key features of the new circuit board is its flexibility, which allows it to be bent and curved without sacrificing performance. This opens up a wide range of possibilities for its use in products such as wearable devices, flexible displays, and medical implants. In addition, its slim profile makes it an ideal solution for space-constrained applications where traditional circuit boards would be too bulky."We are thrilled to introduce our ultra-thin circuit board to the market," said [Spokesperson], CEO of [Company name]. "This breakthrough technology represents a significant advancement in the field of electronics, and we believe it will pave the way for a new generation of innovative products and devices."In addition to its remarkable thinness and flexibility, the new circuit board also boasts impressive electrical performance. Its high-density interconnects and advanced materials ensure low signal loss and high-speed transmission, making it suitable for a wide range of high-performance applications. Furthermore, the board's robust design and materials make it resistant to environmental factors such as moisture, temperature variations, and mechanical stress.[Company name] is already in discussions with several major electronics manufacturers to bring the new circuit board technology to market. The company expects that the technology will be incorporated into a variety of consumer and industrial products in the near future, with the potential to revolutionize the way we interact with electronics.In addition to its ultra-thin circuit board, [Company name] offers a wide range of innovative solutions for the electronics industry. From advanced semiconductor materials to cutting-edge packaging and interconnect technologies, the company is committed to pushing the boundaries of what is possible in electronic design and manufacturing.With a proven track record of delivering high-quality, reliable products, [Company name] has earned a reputation as a trusted partner for leading electronics manufacturers around the world. The company's state-of-the-art manufacturing facilities, experienced team of engineers, and dedication to innovation make it a go-to source for next-generation electronic solutions.In conclusion, [Company name]'s unveiling of their ultra-thin circuit board represents a major milestone in the electronics industry. This groundbreaking technology is set to open up new possibilities for product design and innovation, with its unparalleled thinness, flexibility, and performance. As the company continues to drive the advancement of electronic solutions, we can expect to see even more pioneering technologies emerge in the near future.

Step-by-step guide to surface mount assembly process

[Company Name] is a leading provider of innovative electronic solutions, serving a diverse range of industries such as automotive, consumer electronics, telecommunications, and medical devices. With a strong focus on cutting-edge technology and exceptional quality, [Company Name] has established itself as a key player in the field of electronic manufacturing services.Recently, [Company Name] unveiled its advanced Surface Mount Assembly Process, showcasing its commitment to staying at the forefront of technological advancements in the industry. The Surface Mount Assembly Process is a critical step in the production of electronic components and plays a pivotal role in the overall performance and reliability of the final product.The Surface Mount Assembly Process at [Company Name] utilizes state-of-the-art equipment and precision engineering to ensure that electronic components are seamlessly integrated onto the surface of the printed circuit board (PCB). This process is essential for creating compact and high-density electronic assemblies, which are increasingly in demand in today's fast-paced technological landscape.One of the key advantages of [Company Name]'s Surface Mount Assembly Process is its ability to accommodate a wide range of component sizes and package types, making it suitable for a diverse array of electronic products. Whether it's small and delicate components for handheld devices or larger components for industrial applications, [Company Name] has the capability to handle it all with utmost precision and efficiency.Furthermore, the Surface Mount Assembly Process at [Company Name] is designed to meet the strictest quality standards. The company adheres to rigorous quality control measures at every stage of the assembly process, ensuring that the finished products meet or exceed customer expectations. This commitment to quality is further reinforced by [Company Name]'s adherence to industry certifications and standards, demonstrating its dedication to delivering reliable and high-performance electronic solutions.In addition to its cutting-edge technology and stringent quality control, [Company Name] takes pride in its team of highly skilled and experienced professionals. The company's engineers and technicians are equipped with the expertise and knowledge to handle complex surface mount assembly challenges, providing customers with the confidence that their electronic products are in capable hands.With the unveiling of its advanced Surface Mount Assembly Process, [Company Name] aims to further cement its position as a leader in electronic manufacturing services. By offering a comprehensive and reliable solution for surface mount assembly, the company seeks to address the evolving needs of its customers and contribute to the advancement of technological innovation across various industries.In conclusion, [Company Name] continues to set new benchmarks in electronic manufacturing services with the introduction of its advanced Surface Mount Assembly Process. With a focus on cutting-edge technology, uncompromising quality, and a team of skilled professionals, the company is well-positioned to meet the increasingly complex demands of the electronic industry. As [Company Name] looks ahead, it remains committed to driving innovation and delivering exceptional electronic solutions that exceed customer expectations.

Efficient Surface Mount PCB Soldering Techniques for High-Quality Assembly

Surface mount PCB soldering is a critical process in the manufacturing of electronic devices. It involves the attachment of electronic components to a printed circuit board (PCB) using solder paste and a reflow soldering process. This process is vital for ensuring the reliability and functionality of the electronics and requires advanced machinery and expertise.Relying on technology and expertise, {company name} has established itself as a leader in the surface mount PCB soldering industry. With a commitment to precision and quality, the company has become a trusted partner for businesses across various industries, including automotive, aerospace, telecommunications, and consumer electronics.{Company name} specializes in providing comprehensive surface mount PCB soldering solutions, handling a wide range of PCB sizes and complexities. The company's state-of-the-art facilities are equipped with advanced machinery and technology, allowing for precise and efficient soldering processes.One of the key aspects of {company name}'s surface mount PCB soldering capability is its adherence to strict quality control measures. The company employs a team of highly skilled technicians who are trained to ensure that every soldering process meets the highest industry standards. Additionally, {company name} utilizes cutting-edge inspection equipment to verify the quality and reliability of the solder joints, guaranteeing that the finished PCBs meet the client's specifications and expectations.{Company name} also prides itself on its ability to accommodate custom requirements and tight production schedules. The company works closely with its clients to understand their specific needs and deliver tailored surface mount PCB soldering solutions that meet their unique requirements. This level of personalized service has earned {company name} a reputation for reliability and flexibility in the industry.In addition to its technical expertise, {company name} places a strong emphasis on environmental sustainability and social responsibility. The company has implemented green manufacturing practices and adheres to strict environmental regulations, ensuring that its operations have minimal impact on the environment. Furthermore, {company name} is committed to ethical business practices and upholds the highest standards of integrity and transparency in all its dealings.{Company name} is constantly seeking to innovate and improve its surface mount PCB soldering capabilities. The company invests in research and development to stay at the forefront of technological advancements in the industry. By staying ahead of the curve, {company name} can continue to provide its clients with the most cutting-edge and reliable surface mount PCB soldering solutions.As the demand for high-quality electronics continues to grow, {company name} remains dedicated to meeting the ever-evolving needs of its clients. The company's unwavering commitment to excellence and customer satisfaction has solidified its position as a trusted leader in the surface mount PCB soldering industry. Looking ahead, {company name} is poised to continue its growth and success by delivering innovative solutions and unparalleled service to its clients.

High-Quality Empty PCB Board for Sale - Find the Best Deals Today!

The leading supplier of electronic components and solutions, {company name}, has recently announced the launch of their latest product - Empty PCB Boards. These boards are designed to provide a versatile and highly customizable platform for electronic circuitry, offering a wide range of applications across various industries.Empty PCB Boards are an essential component in the manufacturing of electronic devices and equipment. They serve as the foundation for creating complex circuit designs, providing a solid base for mounting and interconnecting electronic components such as resistors, capacitors, and integrated circuits. With the rapid advancement of technology, the demand for high-quality, reliable PCB boards has grown significantly, and {company name} is proud to offer a solution that meets these evolving needs.What sets {company name}'s Empty PCB Boards apart is their exceptional quality and durability. Each board is constructed using high-grade materials and cutting-edge manufacturing processes, ensuring optimal performance and reliability. In addition, {company name} offers a wide range of customization options, allowing customers to tailor the boards to their specific requirements. Whether it's a specific size, shape, or configuration, {company name} can deliver a solution that meets the unique needs of each customer.The applications for Empty PCB Boards are vast and varied. From consumer electronics and telecommunications to automotive and industrial equipment, these boards play a critical role in powering the electronic devices and systems that shape our modern world. With {company name}'s comprehensive range of Empty PCB Boards, businesses and manufacturers can find the perfect solution for their specific application, helping them to stay ahead in a competitive market.In addition to their exceptional product quality, {company name} is also committed to providing top-notch customer service and support. Their team of experts is on hand to assist customers with selecting the right PCB board for their needs, offering technical guidance and expertise every step of the way. This dedication to customer satisfaction sets {company name} apart as a trusted and reliable partner in the electronic components industry.As part of their commitment to sustainability, {company name} also places a strong emphasis on environmental responsibility in the manufacturing of their Empty PCB Boards. By adhering to strict environmental standards and best practices, they strive to minimize their impact on the environment and contribute to a more sustainable future.With the launch of their Empty PCB Boards, {company name} has once again demonstrated their dedication to innovation and excellence in the electronic components industry. By offering a high-quality, customizable solution that meets the diverse needs of their customers, they continue to set the standard for excellence in the market.For businesses and manufacturers seeking reliable, high-quality Empty PCB Boards, {company name} is the go-to partner. With their extensive product range, commitment to customer satisfaction, and focus on sustainability, they are poised to meet the evolving needs of the electronic components market and remain a leader in the industry.

Top-Tier Gold PCBs: The Latest Innovation in Tech Manufacturing

Gold PCBs have become an essential component in the electronics industry, and the demand for high-quality gold PCBs is on the rise. One company that has been leading the way in producing top-notch gold PCBs is {Company Name}.{Company Name} is a renowned manufacturer of gold PCBs, and they have been at the forefront of delivering cutting-edge PCB solutions to their clients. Their commitment to innovation and quality has helped them establish themselves as a market leader in the industry.Gold PCBs are highly sought after for their superior performance and reliability. The use of gold in PCBs offers a number of distinct advantages, including excellent conductivity and corrosion resistance. This makes gold an ideal material for use in high-reliability applications and industries such as aerospace, defense, and medical devices.{Company Name} has a state-of-the-art manufacturing facility that is equipped with the latest technologies and processes to ensure the production of top-quality gold PCBs. They employ a team of highly skilled engineers and technicians who are dedicated to delivering exceptional products that meet the unique requirements of their clients.In addition to their superior manufacturing capabilities, {Company Name} also prides itself on their commitment to environmental sustainability. They have implemented a number of eco-friendly practices throughout their production process, ensuring that they minimize their impact on the environment.One of the key factors that sets {Company Name} apart from their competitors is their dedication to customer satisfaction. They work closely with their clients to understand their specific needs and requirements, and then tailor their products and services to meet those demands. This personalized approach has earned {Company Name} a reputation for delivering exceptional customer service and support.As the demand for gold PCBs continues to grow, {Company Name} has been positioning themselves to meet the needs of the market. They have been investing in research and development to stay ahead of the curve and develop new products and technologies that push the boundaries of what is possible with gold PCBs.The commitment to excellence and innovation that {Company Name} has demonstrated has not gone unnoticed. They have received accolades and recognition from industry organizations for their contributions to the field of PCB manufacturing. Their dedication to quality and customer satisfaction is a testament to their position as a leader in the industry.Looking ahead, {Company Name} is poised to continue their success and maintain their position as a premier manufacturer of gold PCBs. With their focus on innovation, quality, and customer satisfaction, they are well-equipped to meet the evolving needs of the electronics industry and the growing demand for high-quality gold PCBs.

Durable and Flexible Polyimide Material for a Variety of Applications

Polyimide Flex (PI) has been making headlines in the world of advanced materials and technology. The versatile and high-performance nature of polyimide film has found its way into countless applications, thanks to its exceptional thermal, chemical, and mechanical properties. From aerospace and automotive industries to electronics and medical technology, Polyimide Flex has been a game-changer in various sectors.The company that produces Polyimide Flex, has been at the forefront of developing innovative solutions for the ever-evolving needs of its customers. With a strong focus on research and development, the company has continuously expanded its product range and capabilities to cater to a wide range of industries and applications.With a long-standing history of expertise in the field of advanced materials, the company has been able to consistently deliver high-quality polyimide films that meet the stringent requirements of modern-day technologies. Its state-of-the-art manufacturing facilities and stringent quality control measures ensure that each roll of Polyimide Flex meets the highest standards of performance and reliability.One of the key advantages of Polyimide Flex is its ability to withstand extreme conditions, making it an ideal choice for applications that require durability and reliability. Its superior thermal stability enables it to withstand high temperatures, making it suitable for use in harsh environments such as aerospace and automotive applications. Additionally, its excellent chemical resistance makes it suitable for use in electronic and medical applications where exposure to solvents and harsh chemicals is common.Moreover, Polyimide Flex is known for its exceptional electrical insulation properties, making it an ideal choice for electrical and electronic applications. Its ability to maintain its dielectric strength at high temperatures makes it a preferred choice for flexible printed circuits, electrical insulation, and aerospace wire and cable applications.The company's commitment to sustainability and environmental responsibility is evident in its approach to manufacturing Polyimide Flex. The company has implemented various eco-friendly initiatives to minimize its environmental impact, such as reducing waste generation and energy consumption. Additionally, the company is committed to complying with all relevant environmental regulations and standards to ensure that its products are produced in an environmentally responsible manner.With a strong focus on customer satisfaction, the company has built a reputation for providing excellent customer service and technical support. Its team of dedicated professionals is always ready to assist customers with product selection, technical specifications, and application support to ensure that they get the most out of Polyimide Flex in their specific applications.Looking to the future, the company is committed to continuous innovation and development in the field of advanced materials. It is constantly exploring new technologies and materials to expand its product portfolio and meet the evolving needs of its customers in various industries. By staying at the forefront of technological advancements, the company aims to remain a trusted partner for its customers and continue to drive progress and innovation in the field of advanced materials.In conclusion, Polyimide Flex from (company name) has proven to be an indispensable material in countless applications due to its exceptional properties and performance. With a strong commitment to quality, innovation, and sustainability, the company has positioned itself as a leader in the field of advanced materials and is well-equipped to meet the diverse and evolving needs of its customers in various industries for years to come.