How to Source High-Quality PCBA for Fast Turnaround Times

By:Admin

Fast PCBA prides itself on its state-of-the-art facilities, which are equipped with the latest machinery and technology to ensure the highest level of precision and quality in every PCB assembly. Their team of highly skilled engineers and technicians are dedicated to delivering top-notch PCBAs that meet and exceed the expectations of their clients.

One of the key factors that sets Fast PCBA apart from the competition is their focus on speed and efficiency. With their streamlined production processes and rigorous quality control measures, Fast PCBA is able to offer fast turnaround times without compromising on the quality of their products. This has made them a preferred partner for businesses in a wide range of industries, including telecommunications, automotive, consumer electronics, and medical devices.

In addition to their commitment to delivering top-quality products in a timely manner, Fast PCBA also places a strong emphasis on customer satisfaction. They work closely with each client to understand their unique needs and specifications, and tailor their services to ensure that every project is completed to the highest standard. This dedication to customer service has earned them a stellar reputation in the industry and a loyal base of satisfied clients.

Fast PCBA's comprehensive range of services includes PCB assembly, prototype assembly, turnkey assembly, and PCB manufacturing. They are capable of handling projects of all sizes and complexities, from small-scale prototypes to large-scale production runs. Whether a client requires a single PCB assembly or a complete turnkey solution, Fast PCBA has the expertise and resources to deliver.

The company's commitment to innovation and continuous improvement is evident in their ongoing investment in research and development. They are constantly exploring new technologies and methodologies to further enhance the quality and efficiency of their PCBA services, staying ahead of industry trends and standards.

As demand for electronic devices continues to grow, Fast PCBA is well-positioned to meet the needs of businesses looking for reliable and high-quality PCB assembly solutions. With their unwavering commitment to excellence, cutting-edge technology, and dedication to customer satisfaction, Fast PCBA has established itself as a leader in the electronics manufacturing industry.

In conclusion, Fast PCBA's reputation for superior quality, speed, and customer service has made them a trusted partner for businesses seeking top-tier PCB assembly solutions. Their commitment to innovation and continuous improvement ensures that they stay at the forefront of the industry, meeting the evolving needs of their clients. Fast PCBA is poised for continued success as a provider of high-quality PCB assembly services.

Company News & Blog

High-quality quick-turn PCB assembly services for fast prototyping

***NEWS***Quick Turn PCB Assembly Services Offered by [Company Name][Company Name] is a leading provider of quick turn PCB assembly services for a wide range of industries and applications. With state-of-the-art facilities and a team of highly skilled professionals, [Company Name] is committed to delivering quality PCBs with fast turnaround times.With the increasing demand for quick turn PCB assembly services in the electronics industry, [Company Name] has positioned itself as a reliable partner for companies looking to speed up their product development cycles. The company offers a comprehensive range of services, including prototype PCB assembly, low volume production, and quick turn assembly for urgent projects.One of the key factors that sets [Company Name] apart from its competitors is its ability to deliver high-quality PCBs with quick turnaround times. The company understands the importance of speed and reliability in the electronics industry, and has invested in cutting-edge production equipment and streamlined processes to meet the tight deadlines of its customers.In addition to quick turn PCB assembly services, [Company Name] also offers design for manufacturing (DFM) support to help customers optimize their PCB designs for efficient and cost-effective assembly. By working closely with customers during the early stages of product development, [Company Name] is able to identify and address potential manufacturing challenges, resulting in faster production cycles and higher-quality PCBs.Furthermore, [Company Name] prides itself on its commitment to quality and customer satisfaction. The company follows strict quality control procedures at every stage of the PCB assembly process, ensuring that all products meet the highest industry standards. Additionally, [Company Name] offers personalized customer support to guide customers through the entire assembly process, from design and prototyping to production and delivery.With its quick turn PCB assembly services, [Company Name] serves a diverse range of industries, including aerospace, automotive, medical devices, telecommunications, and consumer electronics. The company has the flexibility to handle various PCB types, including rigid, flex, and rigid-flex boards, as well as different technologies such as surface mount technology (SMT) and through-hole assembly.As an industry leader in quick turn PCB assembly, [Company Name] is continuously innovating and improving its processes to meet the evolving needs of its customers. The company stays abreast of the latest advancements in PCB technology and manufacturing techniques to offer cutting-edge solutions that drive efficiency and reliability.In conclusion, [Company Name] is a trusted provider of quick turn PCB assembly services for companies seeking fast and reliable production of high-quality PCBs. With its commitment to quality, customer satisfaction, and continuous improvement, [Company Name] is well-positioned to meet the growing demand for quick turn PCB assembly in the electronics industry.For more information about [Company Name] and its quick turn PCB assembly services, please visit [company website] or contact [company contact information].Contact:[Company Name][Company Address][Company Phone Number][Company Email Address][Company Website]

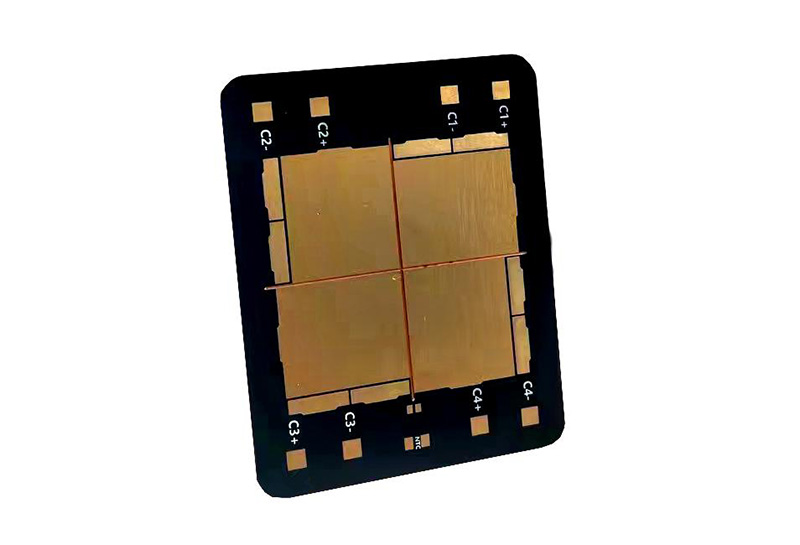

Top-Tier Gold PCBs: The Latest Innovation in Tech Manufacturing

Gold PCBs have become an essential component in the electronics industry, and the demand for high-quality gold PCBs is on the rise. One company that has been leading the way in producing top-notch gold PCBs is {Company Name}.{Company Name} is a renowned manufacturer of gold PCBs, and they have been at the forefront of delivering cutting-edge PCB solutions to their clients. Their commitment to innovation and quality has helped them establish themselves as a market leader in the industry.Gold PCBs are highly sought after for their superior performance and reliability. The use of gold in PCBs offers a number of distinct advantages, including excellent conductivity and corrosion resistance. This makes gold an ideal material for use in high-reliability applications and industries such as aerospace, defense, and medical devices.{Company Name} has a state-of-the-art manufacturing facility that is equipped with the latest technologies and processes to ensure the production of top-quality gold PCBs. They employ a team of highly skilled engineers and technicians who are dedicated to delivering exceptional products that meet the unique requirements of their clients.In addition to their superior manufacturing capabilities, {Company Name} also prides itself on their commitment to environmental sustainability. They have implemented a number of eco-friendly practices throughout their production process, ensuring that they minimize their impact on the environment.One of the key factors that sets {Company Name} apart from their competitors is their dedication to customer satisfaction. They work closely with their clients to understand their specific needs and requirements, and then tailor their products and services to meet those demands. This personalized approach has earned {Company Name} a reputation for delivering exceptional customer service and support.As the demand for gold PCBs continues to grow, {Company Name} has been positioning themselves to meet the needs of the market. They have been investing in research and development to stay ahead of the curve and develop new products and technologies that push the boundaries of what is possible with gold PCBs.The commitment to excellence and innovation that {Company Name} has demonstrated has not gone unnoticed. They have received accolades and recognition from industry organizations for their contributions to the field of PCB manufacturing. Their dedication to quality and customer satisfaction is a testament to their position as a leader in the industry.Looking ahead, {Company Name} is poised to continue their success and maintain their position as a premier manufacturer of gold PCBs. With their focus on innovation, quality, and customer satisfaction, they are well-equipped to meet the evolving needs of the electronics industry and the growing demand for high-quality gold PCBs.

Complete Guide to Through Hole PCB Assembly: Process and Benefits

Through Hole PCB Assembly has become an essential process in the manufacturing industry. It involves the placement of components through holes on a printed circuit board (PCB), which are then soldered to create a secure connection. This process is crucial for creating reliable and durable electronic devices such as industrial machinery, medical equipment, and consumer electronics.{Company} has been a leader in the PCB assembly industry for over a decade, specializing in providing high-quality through hole assembly services to a wide range of clients. With state-of-the-art manufacturing facilities and a team of experienced professionals, {Company} has established a strong reputation for delivering top-notch PCB assembly solutions.The through hole PCB assembly process begins with the preparation of the PCB, which involves drilling holes and applying a layer of copper to create the circuit pathways. Once the PCB is ready, the components are placed through the holes according to the design specifications. This requires precision and accuracy to ensure that the components are aligned correctly and securely in place.{Company} utilizes advanced automated equipment and meticulous quality control measures to ensure that the through hole assembly is performed with the highest level of precision and efficiency. This allows for the production of PCBs with consistent quality and reliability, meeting the stringent requirements of various industries.One of the key advantages of through hole PCB assembly is its ability to handle high-power and high-current applications. Through hole components are typically larger and have stronger connections compared to surface mount components, making them ideal for applications that require robust electrical connections and mechanical stability.{Company} has a diverse portfolio of clients, ranging from small businesses to large corporations, and serves a wide range of industries including aerospace, automotive, telecommunications, and defense. The company's commitment to excellence and customer satisfaction has earned them a loyal customer base and a reputation for delivering reliable, high-quality PCB assembly solutions.In addition to through hole PCB assembly, {Company} also offers a comprehensive range of services including surface mount assembly, PCB design and layout, prototype assembly, and testing. This allows clients to benefit from a one-stop solution for all their PCB assembly needs, streamlining the production process and reducing time-to-market.{Company}'s dedication to innovation and continuous improvement has driven the development of cutting-edge assembly techniques and technologies. Their investment in research and development has allowed them to stay ahead of industry trends and customer demands, while maintaining a competitive edge in the market.As the demand for high-quality through hole PCB assembly continues to grow, {Company} remains committed to providing superior services that meet the evolving needs of the industry. With a focus on quality, precision, and efficiency, {Company} is well-positioned to continue its success as a leading provider of PCB assembly solutions.In conclusion, through hole PCB assembly is a critical process for the manufacturing of reliable and durable electronic devices. {Company} has established itself as a trusted leader in the industry, delivering top-notch through hole assembly services to a diverse range of clients. With a focus on innovation, quality, and customer satisfaction, {Company} is poised to maintain its position at the forefront of the PCB assembly industry for years to come.

High Voltage Spark Testing: What You Need to Know

Spark Test Voltage is a vital part of the quality control process for a wide range of products and materials. It is used to determine the dielectric breakdown voltage of insulating oils and fluids, as well as the electrical insulation of electrical equipment such as transformers, cables, and switchgear. This test is crucial for ensuring the safety and reliability of these products and materials, and it is an essential part of the overall quality control process.The [Company] is a leading provider of high-quality testing and measurement equipment for a wide range of industries. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted provider of reliable and accurate testing solutions. The [Company] has a long history of providing top-quality products and services to its customers, and its commitment to excellence has made it a preferred choice for many businesses around the world.One of the [Company]'s flagship products is its Spark Test Voltage equipment, which is widely used in the electrical and power industries. This equipment is designed to accurately measure the dielectric breakdown voltage of insulating oils and fluids, as well as the electrical insulation of various types of electrical equipment. With its advanced technology and precision engineering, the [Company]'s Spark Test Voltage equipment is known for its reliability, accuracy, and ease of use.The importance of Spark Test Voltage in the quality control process cannot be understated. In the electrical and power industries, the reliability and safety of equipment and materials are of utmost importance. Without accurate and precise testing methods, it would be impossible to ensure that these products and materials meet the necessary standards and requirements. This is where the [Company]'s Spark Test Voltage equipment plays a crucial role, providing businesses with the means to effectively test and measure the dielectric breakdown voltage and electrical insulation of their products and materials.In addition to its reliability and accuracy, the [Company]'s Spark Test Voltage equipment is also highly user-friendly. With intuitive controls and easy-to-read displays, this equipment is designed to be highly accessible to operators of all skill levels. This ensures that businesses can carry out their quality control processes with confidence, knowing that they have a reliable and user-friendly testing solution at their disposal.Moreover, the [Company] also provides exceptional customer support and service, ensuring that businesses can get the most out of their Spark Test Voltage equipment. With a team of knowledgeable and experienced professionals, the company is committed to helping its customers with any questions or issues they may have. This level of support is invaluable to businesses, as it ensures that they can effectively integrate the Spark Test Voltage equipment into their quality control processes and maximize its benefits.The [Company] is continuously innovating and improving its Spark Test Voltage equipment, staying at the forefront of technological advancements and industry standards. This commitment to excellence ensures that businesses have access to the most advanced and reliable testing solutions available, allowing them to meet and exceed the necessary quality control requirements.In conclusion, the [Company]'s Spark Test Voltage equipment is an essential part of the quality control process for numerous industries. Its reliability, accuracy, and user-friendly design make it a preferred choice for businesses around the world. With exceptional customer support and a commitment to innovation, the [Company] is a trusted provider of high-quality testing and measurement solutions, helping businesses ensure the safety and reliability of their products and materials.

Innovative Multilayer Flexible PCB Technology Offers Enhanced Performance

Multilayer Flex PCB: The Future of Electronic InterconnectivityIn today's fast-paced and interconnected world, the demand for smaller, more flexible, and more efficient electronic devices is higher than ever. As technology advances, so does the need for innovative printed circuit board (PCB) solutions that can keep up with the changing landscape of consumer electronics. One company that is at the forefront of this innovation is {company name}, a leading manufacturer of advanced electronic interconnect solutions.{Company name} specializes in the production of multilayer flex PCBs, which are designed to provide unparalleled flexibility, reliability, and performance for a wide range of electronic applications. These advanced PCBs are constructed using multiple layers of flexible substrate materials, which are combined to form a highly adaptable and durable interconnect solution. The result is a PCB that can be bent, twisted, and shaped to fit into even the most tight and compact electronic devices, without sacrificing performance or reliability.With the increasing demand for smaller and more powerful electronic devices, the need for flexible and reliable interconnect solutions has never been greater. As a leading manufacturer of multilayer flex PCBs, {company name} is committed to providing its customers with the most advanced and innovative interconnect solutions on the market. By leveraging cutting-edge manufacturing techniques and materials, the company is able to produce PCBs that are not only highly flexible and durable but also provide exceptional electrical performance and signal integrity.One of the key advantages of {company name}'s multilayer flex PCBs is their ability to withstand extreme environmental conditions. Whether it is in a high-temperature industrial application or a harsh outdoor environment, these PCBs are designed to provide reliable and consistent performance, even in the most challenging conditions. This makes them an ideal choice for a wide range of applications, including aerospace, automotive, medical, and consumer electronics, where reliability and performance are critical.In addition to their flexibility and reliability, {company name}'s multilayer flex PCBs are also designed to provide exceptional electrical performance. By utilizing advanced materials and construction techniques, the company is able to produce PCBs that offer high-speed signal transmission, low electrical loss, and minimal electromagnetic interference. This makes them an ideal choice for applications that require high-frequency operation, such as wireless communications, data processing, and high-speed computing.{Company name} is also committed to sustainability and environmental responsibility in its manufacturing processes. The company takes a proactive approach to reducing its environmental impact by using environmentally friendly materials and production techniques, and by adhering to strict environmental regulations and standards. This ensures that customers can rely on {company name} not only for high-quality and high-performance products but also for solutions that are eco-friendly and sustainable.As the demand for smaller, more flexible, and more efficient electronic devices continues to grow, the need for advanced interconnect solutions such as multilayer flex PCBs will become increasingly important. {Company name}'s commitment to innovation, quality, and sustainability makes it an ideal partner for companies looking to stay ahead of the curve in the ever-evolving world of electronic interconnectivity. With its advanced manufacturing capabilities, cutting-edge materials, and unwavering commitment to customer satisfaction, {company name} is well-positioned to lead the way in the development of the next generation of electronic interconnect solutions.

Become More Efficient with Laser Stencil Technology

Laser Stencil Technology Revolutionizing Precision ManufacturingIn the world of precision manufacturing, the need for high-quality stencils is crucial for achieving accuracy and consistency in the production process. Laser stencils have emerged as a revolutionary technology that is transforming the way stencils are designed and manufactured. One company at the forefront of this innovation is {company name}, a leading provider of advanced laser stencil solutions.With a dedication to delivering cutting-edge technology and unmatched quality, {company name} has established itself as a trusted partner for manufacturers seeking top-of-the-line stencils. The company's commitment to excellence is evident in their state-of-the-art manufacturing facilities and their team of highly skilled engineers and technicians.Laser stencils are created using advanced laser cutting technology, which allows for the precise and intricate cutting of materials with exceptional accuracy. This method enables {company name} to produce stencils with finer details and tighter tolerances, resulting in superior performance and reliability in the manufacturing process.One of the key advantages of laser stencils is their ability to produce consistent and uniform patterns, ensuring that each component is manufactured to the exact specifications required. This level of precision is essential for industries such as electronics, aerospace, and medical device manufacturing, where the smallest deviation can lead to significant quality issues.Additionally, laser stencils offer enhanced durability and longevity compared to traditional stencils, thanks to the high-quality materials and advanced manufacturing techniques employed by {company name}. This means that manufacturers can rely on {company name}'s stencils to deliver exceptional performance over an extended period, ultimately reducing downtime and improving productivity.Furthermore, {company name} takes a customer-centric approach to its business, working closely with clients to understand their specific requirements and provide tailored solutions to meet their needs. This collaborative process ensures that each stencil is designed and manufactured to exact specifications, allowing for seamless integration into the customer's manufacturing process.The benefits of laser stencils are not limited to their superior quality and performance. They also offer environmental advantages, as the laser cutting process produces minimal waste and consumes less energy compared to traditional manufacturing methods. This sustainability factor is increasingly important for manufacturers looking to minimize their environmental footprint and reduce waste in the production process.{company name} has established itself as a leader in the laser stencil industry through its continuous investment in research and development, as well as its unwavering commitment to delivering excellence in every aspect of its business. The company's dedication to quality and innovation has earned it a reputation as a trusted partner for manufacturers seeking high-performance stencils that meet the demands of today's fast-paced and competitive manufacturing environment.As the demand for precision manufacturing continues to grow, the role of laser stencils in enabling high-quality production processes will become increasingly vital. With its expertise and dedication to innovation, {company name} is well-positioned to lead the way in advancing laser stencil technology and providing manufacturers with the tools they need to achieve exceptional results.In conclusion, laser stencils represent a significant advancement in precision manufacturing, and {company name} is at the forefront of this technology, providing innovative solutions that meet the demands of today's manufacturing industry. With its commitment to quality, performance, and sustainability, {company name} is poised to continue driving the evolution of laser stencil technology and shaping the future of precision manufacturing.

Ultimate Guide to Multi-Layer Flexible PCB Technology

Multi-Layers Flexible PCB: Revolutionizing the Electronics IndustryThe electronics industry is constantly evolving to meet the demands of consumers for smaller, lighter, and more efficient devices. In order to keep up with this demand, manufacturers are continuously looking for new and innovative technologies to integrate into their products. One such technology that is revolutionizing the industry is Multi-Layers Flexible PCB.Multi-Layers Flexible PCB is a type of printed circuit board that offers flexibility and versatility, making it an ideal choice for a wide range of electronic devices. This innovative technology allows for the creation of PCBs with multiple layers of conductive material, which can be bent, twisted, and folded to fit into tight spaces. This flexibility makes it an ideal choice for devices with unique shapes and designs, such as wearable technology, medical devices, and automotive electronics.One company at the forefront of this technology is {}. {}. With over {} years of experience in the electronics industry, {} has established itself as a leader in the development and manufacturing of Multi-Layers Flexible PCB. Their dedication to innovation and quality has made them a trusted partner for many leading electronics companies around the world.{}’s commitment to research and development has enabled them to create Multi-Layers Flexible PCB that meets the highest standards of performance and reliability. Their state-of-the-art manufacturing facilities and advanced production techniques allow them to produce PCBs with precise dimensions and intricate designs, ensuring that they meet the unique requirements of their customers.In addition to their technical expertise, {} also places a strong emphasis on sustainability and environmental responsibility. They have implemented stringent quality control processes to minimize waste and reduce their environmental footprint. By using eco-friendly materials and efficient production methods, they are able to offer Multi-Layers Flexible PCB that not only meets the demands of the industry but also aligns with their commitment to sustainability.The applications of Multi-Layers Flexible PCB are diverse and far-reaching. In the automotive industry, these PCBs are used to create advanced driver assistance systems, infotainment systems, and in-car communication devices. The medical industry benefits from this technology by using it to develop medical devices that are lightweight, durable, and comfortable for patients. In the field of consumer electronics, Multi-Layers Flexible PCBs are used in smartphones, tablets, and wearable devices, enabling manufacturers to create compact and stylish products without compromising on performance.One of the key advantages of Multi-Layers Flexible PCB is its ability to reduce the overall size and weight of electronic devices. This not only makes them more portable and convenient for consumers but also reduces the cost of materials and assembly for manufacturers. Furthermore, the flexibility of these PCBs allows for greater design freedom, which opens up new possibilities for creating innovative and cutting-edge products.As the demand for smaller, more efficient electronic devices continues to grow, Multi-Layers Flexible PCB is set to play a pivotal role in shaping the future of the electronics industry. With continued advancements in technology and manufacturing processes, companies like {} are well-positioned to drive this innovation forward and support the development of next-generation electronic devices.In conclusion, Multi-Layers Flexible PCB is a game-changing technology that is revolutionizing the electronics industry. With its flexibility, versatility, and potential for innovation, it has become an indispensable tool for creating smaller, lighter, and more efficient electronic devices. As companies like {} continue to push the boundaries of this technology, we can expect to see even more exciting developments in the years to come.

Top Active Components for Improved Performance: A Comprehensive Guide

Active Components, a leading provider of electronic components and solutions, has recently announced its expansion to new markets and the introduction of innovative products to meet the evolving needs of its customers.With a strong focus on research and development, Active Components has been at the forefront of technological advancements in the electronic components industry. The company has a proven track record of delivering high-quality products and reliable solutions to a wide range of industries, including automotive, aerospace, telecommunications, and consumer electronics.Active Components prides itself on its ability to anticipate market trends and engineering innovative solutions that address the changing needs of its customers. By leveraging its extensive industry expertise and dedicated team of professionals, the company has been able to stay ahead of the competition and maintain its position as a trusted partner for electronic components.One of the key factors contributing to the success of Active Components is its commitment to continuous improvement and the integration of cutting-edge technologies into its product offerings. The company's extensive product portfolio includes a wide range of electronic components such as microcontrollers, sensors, connectors, and power management solutions, all of which are designed to meet the stringent performance and reliability requirements of modern electronic systems.In line with its expansion efforts, Active Components has identified new market opportunities in emerging industries such as renewable energy, IoT (Internet of Things), and digital healthcare. By strategically aligning its product development and marketing efforts with these growing sectors, the company aims to further diversify its customer base and capitalize on the increasing demand for electronic components in these industries.Furthermore, Active Components has recently introduced a series of groundbreaking products that are poised to revolutionize the electronic components market. These new products leverage the latest advancements in materials science, manufacturing processes, and design technologies to deliver superior performance, enhanced reliability, and cost-effective solutions for its customers.To support its expansion and product development initiatives, Active Components has made significant investments in its manufacturing facilities, research laboratories, and talent acquisition. The company continues to foster a culture of innovation and collaboration, which enables its teams to explore new ideas, push the boundaries of technology, and deliver breakthrough solutions that address the most pressing challenges faced by its customers.In addition to its focus on innovation and expansion, Active Components remains committed to providing exceptional customer service and technical support to its clients. The company takes pride in its ability to build strong and long-lasting partnerships with its customers, understanding their unique requirements, and delivering tailored solutions that meet their specific needs.As Active Components continues to set new standards for quality and innovation in the electronic components industry, the company remains firmly committed to its core values of integrity, excellence, and customer satisfaction. By staying true to these principles and leveraging its technical expertise and industry insights, Active Components is well-positioned to achieve sustained growth and success in the global marketplace.In conclusion, Active Components' expansion efforts and the introduction of innovative products demonstrate the company's unwavering commitment to meeting the evolving needs of its customers and driving progress in the electronic components industry. With its strong focus on innovation, quality, and customer satisfaction, Active Components is poised to solidify its position as a leading provider of electronic components and solutions for years to come.

Quality Inductors: Everything You Need to Know

Common Inductors, a leading manufacturer in the field of electronic components, has been making waves in the industry with its innovative and high-quality products. With a strong commitment to research and development, the company has been able to consistently deliver cutting-edge solutions to its customers. Common Inductors has earned a reputation for excellence and reliability, and its products are trusted by industry professionals around the world.The company’s success can be attributed to its unwavering dedication to quality and customer satisfaction. Common Inductors’ products are known for their superior performance and durability, making them the top choice for a wide range of applications. Whether it’s for automotive, industrial, or consumer electronics, Common Inductors has the expertise and resources to meet the most demanding requirements.One of the key components in Common Inductors’ product lineup is its range of inductors. Inductors are passive electronic components that store energy in the form of a magnetic field, and they are essential in a variety of electronic circuits. Common Inductors offers a comprehensive selection of inductors, including chip inductors, power inductors, and high-frequency inductors, to meet the diverse needs of its customers.The company’s chip inductors are designed for use in compact and high-density circuit boards, where space is at a premium. Despite their small size, Common Inductors’ chip inductors deliver exceptional performance and reliability, making them the ideal choice for today’s miniaturized electronics. The company’s power inductors, on the other hand, are built to handle high currents and operate efficiently in demanding environments. With their robust construction and advanced materials, Common Inductors’ power inductors are capable of meeting the rigorous demands of power electronics.In addition, Common Inductors offers a range of high-frequency inductors that are optimized for use in RF and microwave circuits. These inductors are engineered to deliver superior performance at high frequencies, making them essential for wireless communication and other high-speed applications. With their precise winding and advanced core materials, Common Inductors’ high-frequency inductors are able to achieve low loss and high Q factor, ensuring optimal signal integrity in critical systems.Common Inductors’ commitment to excellence extends beyond its products, as the company also provides comprehensive technical support and customization services to its customers. Its team of experienced engineers is dedicated to assisting customers in finding the best inductor solutions for their specific applications. Whether it’s making modifications to existing products or developing entirely new designs, Common Inductors has the expertise and resources to deliver tailored solutions that meet the unique requirements of its customers.As a global leader in the electronic components industry, Common Inductors is recognized for its technical expertise, product quality, and customer service. The company’s products are widely used in a variety of applications, from consumer electronics and telecommunications to automotive and industrial equipment. With a strong focus on innovation and customer satisfaction, Common Inductors is poised to continue its leadership in the industry and provide advanced solutions for the evolving needs of the electronics market.

How to Check the Voltage of an Outlet: A Step-by-Step Guide

Homeowners are being urged to check the voltage of their electrical outlets following several reports of overloaded circuits and potential fire hazards. With the increasing demand for electricity in modern homes, ensuring that outlets are operating at the correct voltage is crucial for preventing dangerous electrical incidents.{Company name} is a leading provider of electrical safety and maintenance services. With years of experience in the industry, {Company name} has built a reputation for delivering high-quality solutions to homeowners and businesses alike. The company's team of skilled technicians is dedicated to ensuring that electrical systems are safe, efficient, and up to code.In recent months, {Company name} has observed a concerning trend of homeowners experiencing issues with overloaded circuits and electrical fires. Upon further investigation, it was discovered that many of these incidents were caused by outlets operating at an incorrect voltage. This discovery has prompted {Company name} to raise awareness about the importance of checking the voltage of electrical outlets and taking the necessary steps to ensure that they are functioning properly.According to {Company name}'s team of experts, the voltage of an outlet should match the standard voltage for the country in which it is located. In the United States, for example, the standard voltage for residential outlets is 120 volts. If an outlet is operating at a significantly higher or lower voltage, it can lead to a range of safety hazards, including electrical shocks, fires, and damage to electrical devices.To address this issue, {Company name} is encouraging homeowners to invest in a voltage tester, which is a simple and affordable tool that can be used to measure the voltage of electrical outlets. By regularly testing their outlets, homeowners can identify any voltage discrepancies and take appropriate action to rectify the situation.In addition to using a voltage tester, {Company name} recommends that homeowners schedule regular electrical inspections with a qualified professional. An experienced technician can thoroughly assess the electrical system, identify any potential issues, and make the necessary repairs or upgrades to ensure that outlets are operating at the correct voltage.Furthermore, {Company name} emphasizes the importance of being vigilant for warning signs of electrical problems, such as flickering lights, frequent circuit tripping, or burning odors. These indicators may suggest that an outlet is operating at an incorrect voltage or that there are other underlying issues with the electrical system.By raising awareness about the significance of checking outlet voltage, {Company name} aims to empower homeowners to take proactive measures in safeguarding their electrical systems and minimizing the risk of electrical hazards. With the right knowledge and tools at their disposal, homeowners can contribute to creating a safer and more secure environment for themselves and their families.{Company name} is committed to providing comprehensive electrical services that prioritize safety, reliability, and customer satisfaction. With a focus on delivering personalized solutions to meet the unique needs of each client, {Company name} continues to be a trusted resource for all electrical maintenance and safety needs. Whether it's conducting routine inspections, addressing voltage issues, or implementing preventive measures, {Company name} is dedicated to ensuring that electrical systems perform optimally and meet the highest safety standards.