Discover the Process of Multilayer PCB Fabrication for Efficient Electronics Production

By:Admin

{Company Name} is a well-established PCB manufacturer with a strong reputation for delivering high-quality products and exceptional customer service. With years of experience in the industry, they have developed a deep understanding of the intricate needs of electronic manufacturers, and are constantly refining their processes to ensure that they are able to meet the demands of the market.

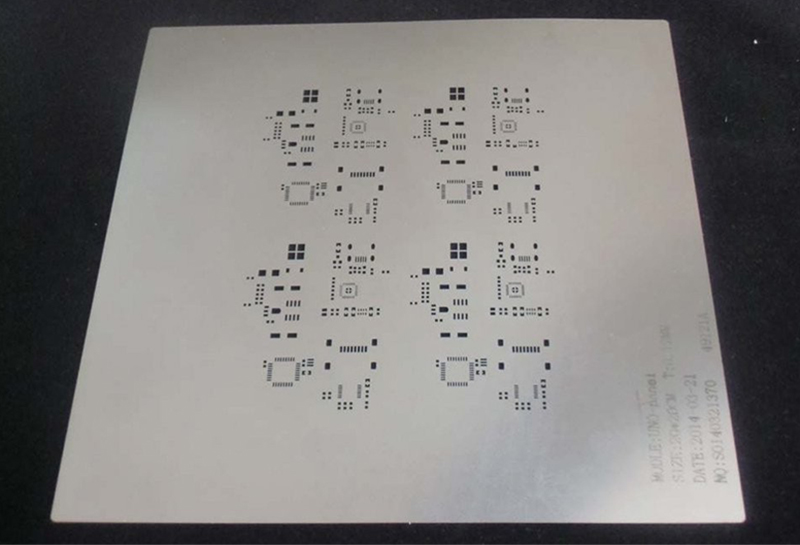

The new multilayer PCB fabrication services offered by {Company Name} are the result of extensive research and development, as well as significant investment in state-of-the-art manufacturing equipment. This has enabled the company to expand their capabilities and offer a wider range of PCB solutions to their clients. With the ability to produce multilayer PCBs with up to 12 layers, {Company Name} is well positioned to meet the needs of a wide variety of industries, including telecommunications, medical devices, aerospace, and more.

One of the key advantages of multilayer PCBs is their ability to accommodate a larger number of components in a smaller space, as well as their ability to provide improved performance and reliability. This makes them an ideal choice for applications that require high-density interconnection and optimal signal integrity. By expanding their capabilities to include multilayer PCB fabrication, {Company Name} is able to offer their clients a more comprehensive range of PCB solutions, and provide them with the flexibility they need to innovate and stay ahead of the curve in their respective industries.

In addition to their technical capabilities, {Company Name} is also known for their commitment to quality and their dedication to providing exceptional customer service. They understand that the success of their clients depends on the performance and reliability of their PCBs, which is why they have implemented stringent quality control measures throughout their manufacturing processes. From the selection of raw materials to the final inspection of finished products, {Company Name} ensures that every step of the fabrication process meets the highest industry standards.

Furthermore, {Company Name} takes pride in their ability to provide personalized support to their clients, offering guidance and expertise at every stage of the PCB manufacturing process. Their team of experienced engineers and technical specialists work closely with clients to understand their specific requirements, and provide tailored solutions that meet their unique needs. This level of personalized support has earned {Company Name} a loyal and satisfied customer base, and has cemented their reputation as a trusted partner in the electronics manufacturing industry.

The launch of {Company Name}'s new multilayer PCB fabrication services is a significant milestone for the company, and reflects their ongoing commitment to innovation and continuous improvement. By expanding their capabilities to include multilayer PCB fabrication, {Company Name} is well positioned to meet the evolving needs of the electronics industry and provide their clients with the high-quality PCB solutions they need to succeed in their respective markets.

With their unwavering dedication to quality, their commitment to customer satisfaction, and their technical expertise, {Company Name} is poised to become a leading provider of multilayer PCB fabrication services. As the demand for high-quality PCBs continues to grow, {Company Name} is well positioned to help their clients stay ahead of the curve and achieve their goals in an increasingly competitive industry.

Company News & Blog

How to Solder Surface Mount Technology (SMT) Parts for Electronics

Soldering SMT Parts with Precision and EfficiencyIn the ever-evolving world of electronic manufacturing, the demand for precise and efficient soldering solutions for surface mount technology (SMT) parts has been on the rise. As a leading provider of electronic manufacturing services, {} has been at the forefront of delivering innovative and reliable solutions to meet this demand. With state-of-the-art facilities and a team of experienced professionals, {} has proven to be a trusted partner for companies seeking high-quality soldering solutions for their SMT parts.At {}'s manufacturing facility, the process of soldering SMT parts is handled with the utmost care and precision. The company utilizes advanced soldering equipment and technology to ensure that each component is soldered with accuracy and consistency. {}'s team of skilled technicians are trained to work with a wide range of SMT parts, including surface mount resistors, capacitors, diodes, and integrated circuits, among others. This versatility enables {} to cater to the diverse needs of their clients, regardless of the complexity or scale of the project.One of the key factors that sets {} apart in the field of soldering SMT parts is their commitment to quality control. The company adheres to strict quality standards and conducts thorough inspections throughout the soldering process to ensure that every part meets the required specifications. This dedication to quality has earned {} a reputation for reliability and excellence, making them a preferred choice for companies seeking high-quality soldering solutions.{}'s dedication to efficiency is another aspect that has positioned them as a leader in the industry. The company continuously invests in advanced machinery and technology to streamline the soldering process, allowing for faster turnaround times without compromising on quality. This commitment to efficiency not only benefits {}'s clients by reducing production lead times but also contributes to cost savings, making their services a cost-effective solution for businesses seeking to optimize their manufacturing processes.With an unwavering focus on customer satisfaction, {} goes the extra mile to provide personalized service and support to their clients. The company collaborates closely with their clients to understand their specific requirements and challenges, allowing them to tailor their soldering solutions accordingly. Whether it's a prototype development project or a large-scale production run, {} is equipped to deliver customized soldering solutions that align with their client's unique needs and objectives.Furthermore, {}'s commitment to sustainability is evident in their efforts to minimize waste and reduce environmental impact in their manufacturing processes. The company adheres to eco-friendly practices and employs energy-efficient technologies, demonstrating their dedication to responsible and sustainable manufacturing.In summary, {} has established itself as a trusted and reliable partner for companies seeking high-quality and efficient soldering solutions for SMT parts. With a focus on precision, quality, efficiency, and customer satisfaction, {} continues to set the benchmark for excellence in the electronic manufacturing industry. As the demand for advanced soldering solutions continues to grow, {} remains fully equipped and prepared to meet the evolving needs of their clients, setting the stage for a future of innovation and success in electronic manufacturing.

Smt Pcb: Latest Developments in Printed Circuit Board Technology

SMT PCB, a leading provider of high-quality printed circuit boards, has recently made significant strides in the realm of technological innovation. With a focus on delivering cutting-edge solutions for a wide range of industries, SMT PCB has established itself as a trusted name in the world of electronic manufacturing.Founded in [year], SMT PCB has quickly risen through the ranks to become a formidable force in the industry. The company's commitment to excellence and customer satisfaction has earned them a loyal customer base, as well as numerous accolades and awards for their superior products and services.One of the key factors that sets SMT PCB apart from its competitors is its relentless pursuit of innovation. The company invests heavily in research and development, constantly pushing the boundaries of what is possible with printed circuit board technology. This dedication to innovation has resulted in the development of numerous groundbreaking products and solutions that have revolutionized the industry.One of the most recent breakthroughs from SMT PCB is the development of a new generation of ultra-thin, high-density printed circuit boards. These boards are specifically designed to meet the growing demand for smaller, more powerful electronic devices. With the proliferation of wearable technology, IoT devices, and other compact electronic products, there is an increasing need for printed circuit boards that can deliver high performance in a small form factor. SMT PCB's new ultra-thin, high-density boards are poised to meet this need, opening up new possibilities for the design and functionality of electronic devices.In addition to their focus on innovation, SMT PCB is also deeply committed to sustainability and environmental responsibility. The company has implemented rigorous environmental management systems to minimize their impact on the environment, and they continue to seek out new ways to reduce waste, energy consumption, and emissions in their manufacturing processes. This commitment to sustainability has earned SMT PCB recognition as a leader in green manufacturing practices.Furthermore, SMT PCB places a strong emphasis on quality control and assurance. The company has implemented strict quality management systems to ensure that every printed circuit board that leaves their facilities meets the highest standards of reliability and performance. With a combination of advanced testing equipment and a team of highly skilled technicians, SMT PCB is able to deliver products that consistently exceed the expectations of their customers.Beyond their impressive technological achievements, SMT PCB is also known for their exceptional customer service. The company takes pride in building strong, long-lasting relationships with their clients, and they are dedicated to providing personalized support and guidance throughout every step of the manufacturing process. This commitment to customer satisfaction has solidified SMT PCB's reputation as a trusted and dependable partner for electronic manufacturers around the world.Looking to the future, SMT PCB shows no signs of slowing down. With a strong foundation of technological expertise, a commitment to sustainability, and a passion for innovation, the company is well-positioned to continue leading the way in the printed circuit board industry. As the demand for smaller, more powerful electronic devices continues to grow, SMT PCB is poised to play a pivotal role in shaping the future of electronic manufacturing.In conclusion, SMT PCB is a company that stands at the forefront of technological innovation. With a track record of excellence, a dedication to sustainability, and a relentless pursuit of innovation, SMT PCB has established itself as a driving force in the industry. As the demand for high-quality printed circuit boards continues to rise, SMT PCB is well-equipped to meet these needs, and to continue pushing the boundaries of what is possible in electronic manufacturing.

Industry Leader to Release New Printed Circuit Board Technology

Smt Pcb, a leading provider of high-quality printed circuit boards, is making waves in the electronics industry with their innovative and reliable products. With a strong commitment to customer satisfaction and a dedication to continuous improvement, Smt Pcb has established itself as a trusted partner for companies in need of top-tier PCB solutions.Since its inception, Smt Pcb has been on a mission to deliver superior PCBs that meet the exact specifications and requirements of their clients. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, they have the capabilities to produce a wide range of PCBs, including single-sided, double-sided, and multi-layer boards. Whether it's for consumer electronics, automotive applications, or industrial equipment, Smt Pcb has the expertise and resources to deliver high-quality PCBs that exceed expectations.One of the key factors that sets Smt Pcb apart from its competitors is its unwavering commitment to quality. The company adheres to strict quality control measures throughout the entire manufacturing process, ensuring that each PCB that rolls off the production line meets the highest standards of reliability and performance. From the selection of raw materials to the final inspection of finished products, Smt Pcb leaves no stone unturned in their quest to deliver flawless PCBs to their clients.In addition to their focus on quality, Smt Pcb is also dedicated to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of the curve and anticipate the evolving needs of the electronics industry. By staying abreast of the latest technological advancements and industry trends, Smt Pcb is able to offer cutting-edge PCB solutions that empower their clients to create innovative and competitive products.Recently, Smt Pcb made headlines with the introduction of a new, groundbreaking PCB technology. This advanced technology promises to revolutionize the way electronic devices are designed and manufactured, offering unprecedented levels of performance, reliability, and flexibility. With this new technology, Smt Pcb aims to empower their clients to push the boundaries of what's possible in the world of electronic devices, opening up a world of new possibilities for innovation and creativity.The introduction of this new PCB technology has generated a wave of excitement and anticipation in the electronics industry, with industry experts and insiders praising Smt Pcb for their forward-thinking approach and dedication to pushing the boundaries of what's possible in PCB manufacturing. The company's commitment to innovation and continuous improvement has positioned them as a trailblazer in the industry, earning them the respect and admiration of their peers and clients alike.Looking ahead, Smt Pcb shows no signs of slowing down. With a strong focus on customer satisfaction, quality, and innovation, the company is poised to continue making waves in the electronics industry and solidify their position as a leading provider of high-quality printed circuit boards. As the demand for advanced PCB solutions continues to grow, Smt Pcb stands ready to meet the needs of their clients and exceed their expectations with best-in-class products and services. For companies in search of reliable, innovative, and high-quality PCB solutions, Smt Pcb remains the partner of choice.

High-Quality Ultrasound PCB Assembly Services for Medical Devices

Ultrasound PCB Assembly: Revolutionizing Medical TechnologyThe demand for advanced medical equipment and technology is on the rise, and one of the key components that is making significant contributions to this industry is ultrasound PCB assembly. With the continuous advancements in medical science and technology, the need for sophisticated and reliable imaging systems has become critical, and ultrasound technology has been at the forefront of this evolution.One company that has been instrumental in the development and manufacturing of ultrasound PCB assemblies is {}. With a strong emphasis on innovation and quality, {} has established itself as a leading player in the PCB assembly industry, particularly in the medical technology sector.{} specializes in the design and production of high-quality PCB assemblies that are specifically tailored to meet the demands of ultrasound technology. From component sourcing to assembly and testing, {} ensures that its PCB assemblies are of the highest standard, meeting the stringent regulatory and quality requirements of the medical industry. The company's commitment to excellence and cutting-edge technology has earned it a reputation for reliability and performance in the field of ultrasound PCB assembly.Ultrasound technology has significantly transformed the field of medical imaging, providing non-invasive and real-time visualization of internal organs and tissues. This has led to its widespread use in various clinical applications, including obstetrics, cardiology, oncology, and general diagnostic imaging. The accuracy and quality of ultrasound imaging depend on the precision and reliability of the PCB assemblies that power the ultrasound systems.The PCB assemblies used in ultrasound technology are highly specialized, incorporating advanced electronic components and circuitry that translate the ultrasound signals into clear and detailed images. These assemblies are also designed to withstand the stringent operating conditions of medical environments, ensuring the safety and effectiveness of the ultrasound systems.In addition to the technical expertise and quality manufacturing capabilities, {} also emphasizes the importance of regulatory compliance and industry standards. The company's ultrasound PCB assemblies undergo rigorous testing and inspection to ensure that they meet the strict requirements for medical device manufacturing. This commitment to quality and compliance underscores {}'s dedication to providing reliable and safe PCB assemblies for ultrasound technology.Furthermore, {}'s capabilities extend beyond manufacturing, as the company also offers comprehensive design and engineering support for custom ultrasound PCB assemblies. This collaborative approach enables {} to work closely with its customers to develop tailored solutions that address specific application requirements, ensuring that the PCB assemblies are optimized for performance, reliability, and cost-efficiency.With the increasing demand for advanced medical imaging technology, the role of ultrasound PCB assembly in driving innovation and progress in the medical industry cannot be overstated. Companies like {} play a pivotal role in this ecosystem, providing the technological backbone that powers the next generation of ultrasound systems.As the medical technology landscape continues to evolve, it is clear that ultrasound PCB assembly will remain a critical component in advancing the capabilities of ultrasound imaging. With its expertise, dedication to quality, and commitment to innovation, {} is well-positioned to be a key contributor to the ongoing advancements in ultrasound technology, ultimately benefiting healthcare professionals and patients worldwide.

High-Quality PCB Inductor for Your Electronic Devices

The demand for electronic components has been increasing significantly in recent years, driven by the growing use of electronic devices in various industries. In response to this demand, [company name] has been working tirelessly to advance the production of state-of-the-art electronic components, including PCB inductors, which play a crucial role in the functionality of electronic devices.PCB (Printed Circuit Board) inductors are essential components in electronic circuits, used to store and release energy in the form of magnetic fields. This allows for the regulation of current and voltage in electronic devices, making them essential for the proper functioning of various electronic systems. As the market for electronic devices continues to expand, the demand for high-quality PCB inductors has been on the rise.[Company name] has been at the forefront of the development and production of PCB inductors, with a strong commitment to quality and innovation. With a team of experienced engineers and researchers, the company has been able to develop cutting-edge PCB inductors that meet the highest standards of performance and reliability. The inductors are designed to withstand the rigors of various applications, from consumer electronics to industrial systems, making them suitable for a wide range of electronic devices.One of the key features of [company name]'s PCB inductors is their compact and lightweight design, which allows for easy integration into electronic circuits without adding unnecessary bulk or weight. This is particularly important for mobile and wearable devices, where space and weight are significant factors. In addition, the inductors are designed to operate efficiently at high frequencies, making them suitable for use in advanced electronic systems.To ensure the quality and reliability of its PCB inductors, [company name] has implemented stringent testing and quality control procedures throughout the production process. This includes thorough inspection of raw materials, precision manufacturing processes, and rigorous performance testing. As a result, the company has been able to consistently deliver PCB inductors that meet or exceed industry standards for performance and reliability.In addition to its commitment to product quality, [company name] has also focused on environmental sustainability in the production of its PCB inductors. The company utilizes eco-friendly materials and manufacturing processes, ensuring that its products have minimal impact on the environment. This commitment to sustainability has not only helped [company name] reduce its environmental footprint but has also resonated with environmentally conscious customers.Looking ahead, [company name] is poised to continue its leadership in the development and production of PCB inductors. The company's ongoing research and development efforts are focused on further enhancing the performance and efficiency of its inductors, in line with the evolving needs of the electronics industry. By staying at the forefront of technological advancements, [company name] is well-positioned to meet the growing demand for high-quality PCB inductors across various industries.In conclusion, PCB inductors are fundamental components in electronic circuits, and their demand is on the rise as electronic devices become increasingly pervasive. [Company name] has emerged as a leading manufacturer of high-quality PCB inductors, leveraging its expertise in engineering, research, and sustainability. With a commitment to innovation and quality, [company name] is set to meet the evolving needs of the electronics industry and continue to be a trusted supplier of PCB inductors for diverse applications.

Comparing Rigid and Flexible PCB: Understanding the Differences

Rigid and Flexible PCBs are some of the most essential components in modern electronic devices. Whether it's a smartphone, a computer, a car, or a medical device, PCBs play a crucial role in the functionality of these devices. {Company name} has been at the forefront of PCB manufacturing for over two decades. With a strong emphasis on quality, innovation, and customer satisfaction, {company name} has established itself as a trusted supplier of rigid and flexible PCBs to a wide range of industries including telecommunications, automotive, aerospace, and consumer electronics.Rigid PCBs are the traditional and most common type of PCB used in electronic devices. These boards are made of solid substrate materials such as fiberglass, and they are capable of supporting heavy components. Rigid PCBs are ideal for applications where durability and stability are paramount, such as in automotive electronics and industrial control systems.On the other hand, flexible PCBs are designed to be more versatile and adaptable to the shape and size requirements of the device they are used in. These boards are made of flexible substrate materials such as polyimide, which allows them to be bent, twisted, and folded without compromising their functionality. Flexible PCBs are widely used in portable electronic devices such as smartphones, tablets, and wearable technology.{Company name} has a comprehensive range of capabilities in the production of both rigid and flexible PCBs. Its state-of-the-art manufacturing facilities are equipped with advanced machinery and technology to ensure the highest quality and precision in every PCB produced. The company's team of experienced engineers and technicians are well-versed in the latest industry standards and best practices, allowing them to deliver PCB solutions that meet the most stringent requirements of their customers.In addition to its standard PCB offerings, {company name} also specializes in the design and production of custom PCBs tailored to the specific needs of its clients. Whether it's a complex multilayer rigid PCB for a telecommunications infrastructure project or a flexible PCB for a cutting-edge medical device, {company name} has the technical expertise and production capacity to deliver high-quality, custom PCB solutions.One of the key factors that sets {company name} apart from its competitors is its unwavering commitment to quality and reliability. The company adheres to strict quality control processes at every stage of the production cycle, from raw material inspection to final product testing. This rigorous approach to quality has earned {company name} the trust and confidence of its customers, who rely on the company for PCB solutions that perform consistently and reliably in their applications.Furthermore, {company name} is dedicated to environmental sustainability and ethical manufacturing practices. The company is certified to the highest industry standards for environmental management and occupational health and safety, demonstrating its commitment to minimizing its environmental footprint and ensuring the well-being of its employees.Looking ahead, {company name} continues to invest in research and development to stay at the forefront of PCB technology. The company is actively exploring new materials, processes, and design techniques to push the boundaries of what is possible in PCB manufacturing. By embracing innovation and continuous improvement, {company name} aims to remain a leader in the PCB industry and a go-to partner for companies seeking reliable and high-quality PCB solutions.In conclusion, {company name} is a reputable and reliable supplier of rigid and flexible PCBs for a wide range of industries. With its advanced manufacturing capabilities, commitment to quality, and dedication to innovation, {company name} is well-positioned to meet the evolving needs of the electronics industry and continue to serve as a trusted partner for its customers.

- The Latest Advancements in Artificial Intelligence and PCB Technology

Artificial Intelligence PCBs Revolutionizing the Electronics IndustryArtificial intelligence (AI) has become an integral part of many industries, and the electronics sector is no exception. With the increasing demand for smart and connected devices, the need for efficient and intelligent electronics components has never been greater. The introduction of AI-enabled printed circuit boards (PCBs) has brought about a revolution in the electronics industry, offering unprecedented levels of performance, efficiency, and adaptability.One company at the forefront of this revolution is {}. With a proven track record of innovation and excellence, {} has developed cutting-edge AI PCBs that are set to redefine the electronics landscape. By integrating AI technology directly into the PCBs, {} has created a range of products that offer enhanced functionality, improved reliability, and accelerated performance.The integration of AI into PCBs has opened up a world of possibilities for the electronics industry. Traditional PCBs are limited in their ability to adapt to changing conditions, but AI-enabled PCBs have the capability to learn and evolve, making them far more versatile and adaptable. This means that devices equipped with AI PCBs can optimize their performance in real-time, leading to improved energy efficiency, faster processing speeds, and enhanced user experiences.One of the key advantages of AI PCBs is their ability to analyze and interpret data in real-time. By leveraging machine learning algorithms, these PCBs can make sense of complex data sets and make intelligent decisions based on the information they gather. This has significant implications for a wide range of applications, from consumer electronics to industrial automation, where the ability to process and act upon data quickly and accurately is critical.Furthermore, AI PCBs have the potential to revolutionize the concept of predictive maintenance. By continuously monitoring the performance of electronic systems and identifying potential issues before they arise, AI-enabled PCBs can help prevent costly downtime and maintenance issues. This not only improves the reliability of electronic devices but also reduces the total cost of ownership for end-users.In addition to their performance benefits, AI PCBs also have the potential to significantly reduce the environmental impact of electronic devices. By optimizing energy consumption and reducing waste, these PCBs can contribute to the development of more sustainable and eco-friendly electronics.{}'s commitment to innovation and excellence has positioned them as a leader in the development of AI PCBs. Through continuous research and development efforts, they have been able to create a range of AI-enabled PCBs that are not only technologically advanced but also practical and cost-effective.As the demand for smarter and more efficient electronics continues to grow, the role of AI-enabled PCBs in driving this transformation is set to become increasingly significant. By offering unparalleled levels of performance, adaptability, and intelligence, these PCBs are poised to reshape the future of the electronics industry, opening up new possibilities for innovation and advancement.In conclusion, the integration of AI technology into PCBs has ushered in a new era of possibilities for the electronics industry. With their ability to learn, adapt, and make intelligent decisions, AI-enabled PCBs are set to revolutionize the way electronic devices are designed, manufactured, and utilized. As a pioneer in this field, {} is driving this revolution forward, and their AI PCBs are expected to play a crucial role in shaping the future of electronics.

Top 10 Multimeter Outlets for 2022: Find the Best Deals on Multimeters

Multimeter Outlet, a leading distributor of high-quality electrical testing equipment, is making waves in the industry with its wide range of products and exceptional customer service. This company has been providing customers with reliable multimeters, clamp meters, and other testing equipment for over a decade, earning a reputation for excellence and reliability.Multimeter Outlet offers a comprehensive selection of multimeters that are suitable for a wide range of applications, from basic electrical troubleshooting to advanced industrial testing. Whether it's for professional electricians, technicians, or DIY enthusiasts, Multimeter Outlet has the right tool for the job. The company's multimeters are known for their accuracy, durability, and user-friendly design, making them a popular choice among professionals and hobbyists alike.In addition to multimeters, Multimeter Outlet also carries a variety of clamp meters, insulation testers, and other electrical testing equipment. These products are designed to meet the needs of professionals in the electrical, HVAC, and automotive industries, as well as enthusiasts who enjoy working on electronic projects at home. With a commitment to quality and customer satisfaction, Multimeter Outlet has become a trusted source for all types of electrical testing equipment.One of the key factors that sets Multimeter Outlet apart from its competitors is its dedication to customer service. The company prides itself on providing exceptional support to its customers, offering expert advice, product demonstrations, and technical assistance. Whether customers are looking for a specific multimeter or need help troubleshooting an electrical issue, the team at Multimeter Outlet is always ready to help.Furthermore, Multimeter Outlet understands the importance of reliability and safety when it comes to electrical testing equipment. The company carefully selects its products from reputable manufacturers, ensuring that customers receive high-quality, dependable tools that meet industry standards. Additionally, Multimeter Outlet provides thorough product information and training resources to help customers use their equipment safely and effectively.As part of its commitment to customer satisfaction, Multimeter Outlet offers competitive pricing, hassle-free returns, and fast shipping options. The company understands that time is of the essence in the electrical industry, and strives to deliver products promptly to help customers stay on schedule and on budget. With a focus on efficiency and convenience, Multimeter Outlet has become a preferred supplier for professionals and enthusiasts alike.In conclusion, Multimeter Outlet is a trusted source for high-quality electrical testing equipment, including multimeters, clamp meters, and insulation testers. With a dedication to customer service, reliability, and safety, the company has established itself as a leader in the industry. Whether customers need a multimeter for basic troubleshooting or specialized testing, Multimeter Outlet has the tools and expertise to meet their needs. For more information, visit their website or contact their knowledgeable team for assistance.

Durable and Convenient Solder Board Holder for Efficient Electronics Work

The Solder Board Holder is an essential tool in the field of electronics and soldering. This versatile device is designed to securely hold circuit boards, allowing technicians and hobbyists to work on them without the risk of damage. The Solder Board Holder has become a staple in workshops and manufacturing facilities around the world, providing a reliable and stable platform for soldering and other electronic work.The Solder Board Holder is made of high-quality materials and features a durable construction that can withstand the rigors of daily use. Its adjustable arms and clamps provide flexibility, allowing users to position circuit boards at various angles for easier access and visibility while working. The holder is also equipped with non-slip feet, ensuring stability and preventing accidental movement during soldering.One of the key features of the Solder Board Holder is its ability to accommodate circuit boards of different sizes. Its adjustable arms and clamps can be easily repositioned to fit various board dimensions, making it a versatile tool for working on a wide range of electronic devices. This flexibility makes the Solder Board Holder a valuable addition to any workshop or production line, where multiple types of circuit boards may need to be worked on.In addition to its utility, the Solder Board Holder is also designed with user comfort in mind. Its ergonomic design reduces strain on the user's hands and wrists, allowing for extended periods of use without discomfort. This is especially important in manufacturing environments, where technicians may need to work on numerous circuit boards in a single day.The Solder Board Holder is a product of {}, a leading manufacturer of electronic accessories and tools. With a strong reputation for quality and reliability, {} has been a trusted name in the industry for over a decade. The company is committed to providing innovative solutions for the electronics market, and the Solder Board Holder is a prime example of their dedication to meeting the needs of technicians and hobbyists alike.{}'s dedication to quality is reflected in the design and construction of the Solder Board Holder. The company uses only the highest quality materials and thorough manufacturing processes to ensure that their products meet the highest standards. This commitment to excellence has earned {} a loyal customer base and a solid reputation as a manufacturer of top-tier electronic accessories and tools.In addition to its commitment to quality, {} also places a strong emphasis on customer satisfaction. The company provides excellent customer service and support, ensuring that their products meet the needs and expectations of their users. With a focus on innovation and reliability, {} has established itself as a leading provider of electronic accessories and tools, with the Solder Board Holder being just one of their many successful products.As the demand for reliable and efficient electronic tools continues to grow, the Solder Board Holder stands out as a trusted and essential device for technicians and hobbyists. Its versatile design, durable construction, and user-friendly features make it an invaluable asset in any workshop or production environment. With the backing of a reputable manufacturer like {}, the Solder Board Holder is sure to remain a staple in the electronics industry for years to come.

How to Source High-Quality PCBA for Fast Turnaround Times

Fast PCBA, a leading provider of high-quality printed circuit board assembly (PCBA) services, is making waves in the electronics manufacturing industry with their advanced technology and commitment to excellence. The company, founded in 2005, has quickly risen to prominence as a trusted partner for businesses seeking reliable and efficient PCBA solutions.Fast PCBA prides itself on its state-of-the-art facilities, which are equipped with the latest machinery and technology to ensure the highest level of precision and quality in every PCB assembly. Their team of highly skilled engineers and technicians are dedicated to delivering top-notch PCBAs that meet and exceed the expectations of their clients.One of the key factors that sets Fast PCBA apart from the competition is their focus on speed and efficiency. With their streamlined production processes and rigorous quality control measures, Fast PCBA is able to offer fast turnaround times without compromising on the quality of their products. This has made them a preferred partner for businesses in a wide range of industries, including telecommunications, automotive, consumer electronics, and medical devices.In addition to their commitment to delivering top-quality products in a timely manner, Fast PCBA also places a strong emphasis on customer satisfaction. They work closely with each client to understand their unique needs and specifications, and tailor their services to ensure that every project is completed to the highest standard. This dedication to customer service has earned them a stellar reputation in the industry and a loyal base of satisfied clients.Fast PCBA's comprehensive range of services includes PCB assembly, prototype assembly, turnkey assembly, and PCB manufacturing. They are capable of handling projects of all sizes and complexities, from small-scale prototypes to large-scale production runs. Whether a client requires a single PCB assembly or a complete turnkey solution, Fast PCBA has the expertise and resources to deliver.The company's commitment to innovation and continuous improvement is evident in their ongoing investment in research and development. They are constantly exploring new technologies and methodologies to further enhance the quality and efficiency of their PCBA services, staying ahead of industry trends and standards.As demand for electronic devices continues to grow, Fast PCBA is well-positioned to meet the needs of businesses looking for reliable and high-quality PCB assembly solutions. With their unwavering commitment to excellence, cutting-edge technology, and dedication to customer satisfaction, Fast PCBA has established itself as a leader in the electronics manufacturing industry.In conclusion, Fast PCBA's reputation for superior quality, speed, and customer service has made them a trusted partner for businesses seeking top-tier PCB assembly solutions. Their commitment to innovation and continuous improvement ensures that they stay at the forefront of the industry, meeting the evolving needs of their clients. Fast PCBA is poised for continued success as a provider of high-quality PCB assembly services.